SINAMICS variable

frequency drives

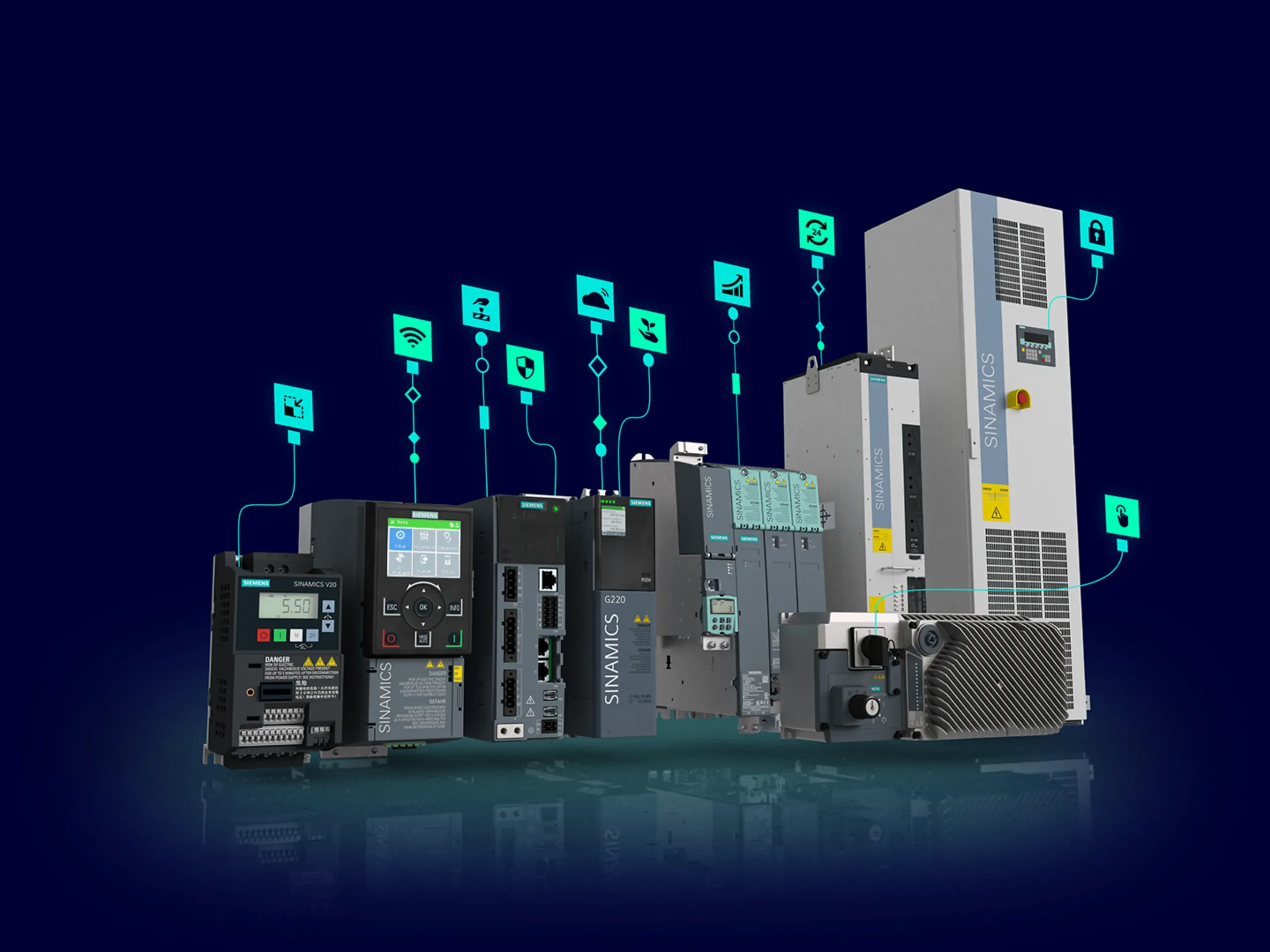

The best option for any driving application is a SINAMICS variable frequency drive. Our drives can accommodate varying voltage ranges, including low, medium, and direct current (DC). Advance your apps to the next generation for a digital and sustainable future with greater efficiency and adaptability.

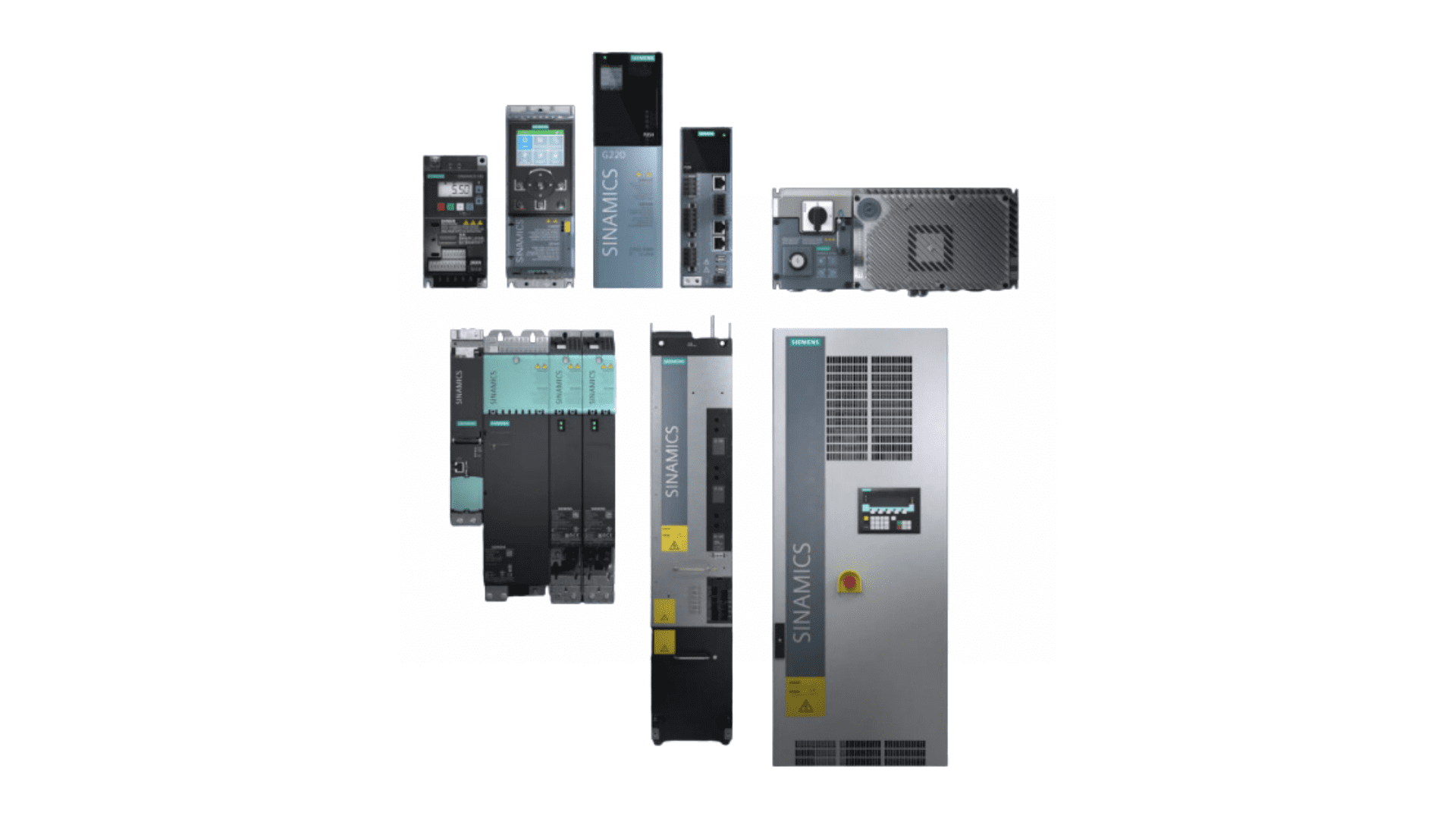

Low voltage drives

A wide range of applications can benefit from low-voltage frequency converters. For instance, when materials need to be positioned, treated, pumped, or compressed. In addition to saving energy, variable-speed operation improves process availability and quality.

Medium voltage drives

converters of intermediate voltage for motor voltages between 1.4 and 13.8 kV. When the needed drive power and/or voltage is too high for low-voltage drive solutions, medium-voltage drive converters for high-voltage motors are utilized to handle specific applications.

Servo drives

The highest dynamic requirements for both single- and multi-axis applications are satisfied by these servo drivers. The ideal choice for numerous applications needing high-precision, dynamic motion control, such as robots, machine tools, packaging machines, continuous material handling, cranes, rolling mills, test stands, and material handling.

DC converters

With many benefits in terms of dependability, usability, and operational performance, DC technology remains the most affordable and well-proven drive solution for a variety of applications due to its dynamic performance, robustness, and affordability.

Motivating uses of the future generation

You need look no further than our SINAMICS variable frequency drives to propel industry innovations. They drive the development of cutting-edge, next-generation applications that cater to the particular requirements of each sector. Our drives encompass everything from moving, positioning, processing, and milling to pumping and ventilation. Prepare to push the boundaries of your applications.

Accelerating the industry’s sustainable and digital transformation

What are some ways to increase production efficiency? Quicken your transition to digital? and develop greater sustainability?

Our SINAMICS variable frequency drives provide the solution. They enable your digital transformation by giving you the data you need to continuously increase production efficiency and sustainability. They are also energy-efficient and versatile enough for any application. With our drives, you can take advantage of extensive lifecycle services, effective engineering and software tools, and integrated safety and security features. Put another way: All the resources you require, both now and in the future, to handle the applications of the future.

1. Drive systems with high efficiency: aim for sustainability

70% of industrial energy is used by electric drives, which have significant cost reduction potential. Our SINAMICS family provides innovative technology and tailored solutions that satisfy both present and future standards.

SINAMICS drives improve energy efficiency, while digitalization turns drive data into valuable insights and increases productivity with Predictive Maintenance Services. We provide the expertise to increase drive productivity, energy efficiency, and resource conservation. Act now with SINAMICS drives for endless possibilities in drive system optimization, achieving about 60% energy savings and sustainable operations through specialized motors, sensors, analytics and Digital Twins.

Decarbonisation

We are constantly improving our drive system output to achieve net zero operations by 2030. Siemens has also started down the path of environmentally friendly purchasing.

Resource efficiency

Our Digital Twins of drives help to design the correct size of the drive train, thus preventing a waste of resources, while drive train lifetime extension can be achieved by condition monitoring and predictive maintenance.

Energy efficiency

Siemens provides state-of-the-art drive technology that satisfies both present and future standards. In addition, the company offers digital solutions for energy transparency that enable system optimisation and around 60% in energy savings.

Circularity

Our services for a circular economy with “Repair, Refurbish and Remanufacture” extend the lifecycle of our drives and further contribute to sustainability.

Drive System Services – analogue or digital

We maintain your production and offer the foundation for further development. We provide a range of services for low-voltage drive systems, including SIMOTICS Motion Control motors and SINAMICS variable frequency drives, and we are available to help in all sectors. Throughout the course of your machine’s lifetime, we will be available to you whenever you need us.

Efficient Motion Control – Time for other perspectives!

Machine builders face many major obstacles as the industry seeks increasingly advanced robotics and motion control solutions. They have to prioritise the safety of both operators and machines, deal with a shortage of competent people, and adjust to growing complexity. Effective motion control systems hold the key to the solution.

2. Safety and Security Integrated

Choosing Safety In addition to guaranteeing technical safety, integrated SINAMICS drives offer thorough support for safety-related issues. Motion control systems that have seamlessly integrated safety technologies, backed by certified parts and engineering in TIA Portal, operate more efficiently.

Validating parameterization and finishing safety control loops from sensors to actuators are the goals of safety acceptance and activation tests. When electromechanical components are removed, wear is eliminated by electronic shutdown, spare costs and maintenance are decreased, and space is reduced. Even when safety reactions are in progress, ongoing diagnostics are ensured via drive communication to the power supply. Personalised safety ideas with PROFIsafe communication facilitate deployment, boost output, and save downtime.

Additionally, we are strengthening SINAMICS drives—and consequently, your computers—against external cyberattacks with the new Security Integrated features.

The right solution for every application

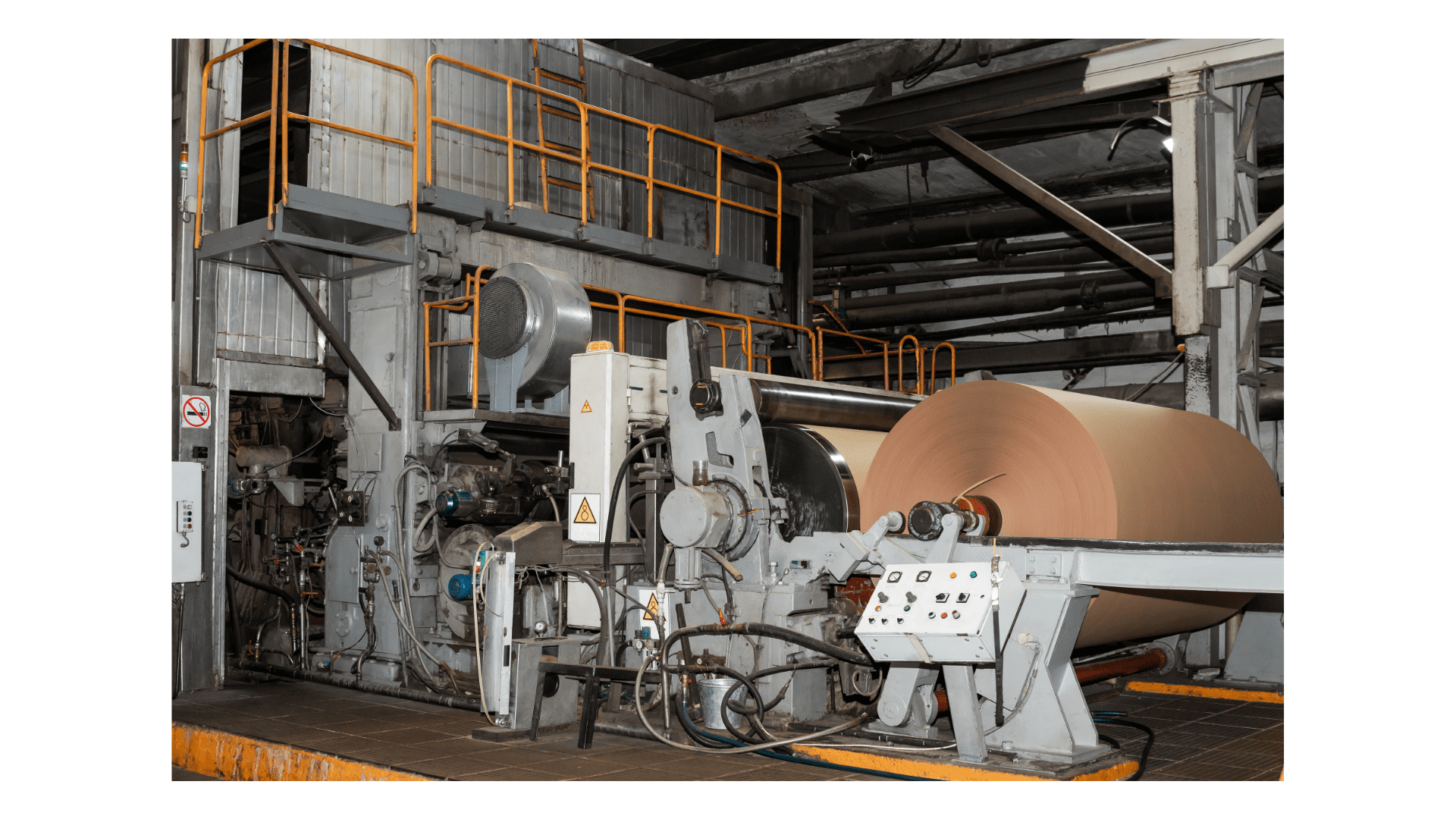

Pumps, fans, and compressors can run continuously and energy-efficiently with the help of SINAMICS. Our drives make it possible to implement durable, energy-efficient solutions for hoisting gear, lifts, and roller or chain conveyors in fundamental conveyor technology. Additionally, SINAMICS guarantees the exact positioning of each axis and permits the coordinated interpolation of many axes, which is useful in intricate robotic or handling applications. For continuous operations requiring high speed and torque precision, including centrifuges, agitators, extruders, and all kinds of production machines, as well as all machining applications, SINAMICS drives are the best option.

SINAMICS – the perfect fit for any industry

We offer solutions to meet current and future challenges in motion control. With its comprehensive features and innovative design, the SINAMICS family can be used in any industry. Our drives ensure that all processes are energy efficient and reliable. The SINAMICS family offers extensive safety features and a high degree of protection which makes it the ideal fit for harsh environments. Industry-specific integrated software features and the Digital Twin help you implement your applications faster and easier.

3. Siemens Xcelerator for Digital Drivetrain

Digital technologies provide safety, sustainability, and efficiency gains without requiring a complete rebuild of the infrastructure. Our Digital Drivetrain portfolio includes all aspects of the workflow, including digital twin simulation for both virtual and physical commissioning and sizing. Platform-spanning communication is facilitated by seamless engineering tools, which also make integration simpler.

Drive data is analysed by cloud or edge apps for event tracking, predictive maintenance, and downtime reduction. Reliability is increased when anomalies are discovered early. Energy optimisation for increased sustainability and efficiency is supported by drive data visibility. Cloud solutions are enhanced by edge computing to enable quick problem-solving. In order to guarantee drivetrain health and effective operation, SINAMICS drives can be connected to Industrial Edge or cloud platforms. This allows for thorough data analysis, anomaly identification, and predictive maintenance using clever algorithms.

Effective Engineering for Automation

Boost your machine development productivity to spur innovation and boost your edge over competitors. Utilise all of the possibilities to create novel machine concepts.

SINAMICS Drive Software – the right function for every application

The SINAMICS Drive Software ensures that our SINAMICS variable frequency drives operate smoothly and reliably. It offers comprehensive functionality, is easily expandable and enables the greatest possible flexibility for a wide range of applications.

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.