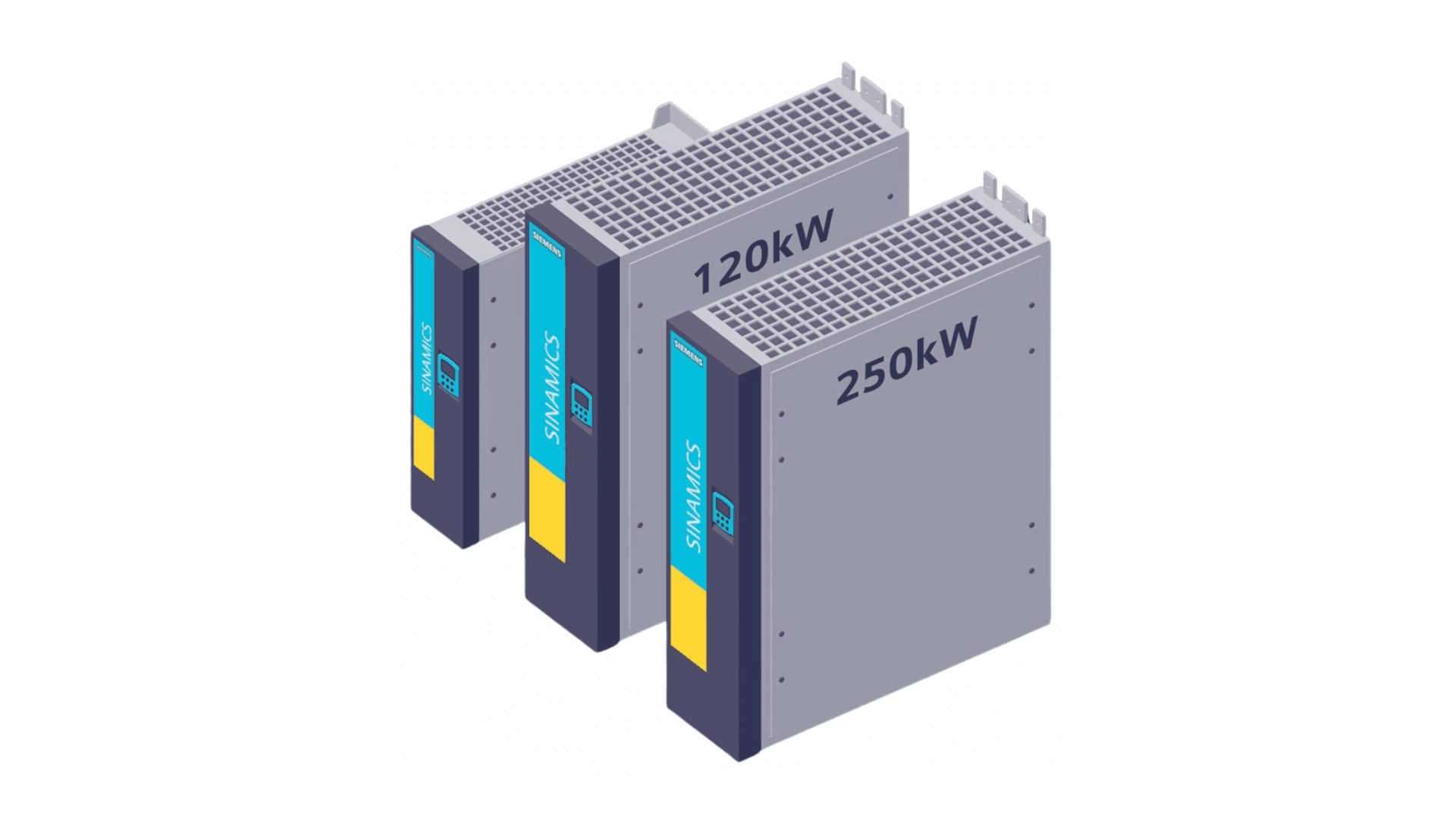

The variable frequency drive for all industries is the SINAMICS G220.

The new high-performance variable frequency drive, SINAMICS G220, is made to tackle issues in every industry, both present and future. SINAMICS G220 elevates digital drive technology to a new level, enhancing application efficiency, security, and future-proofing through enhanced hardware and software.

inventiveness in every little thing

SINAMICS G220 is now capable of handling the problems of the future in all industries, owing to a plethora of novel features.

Efficient

- Utilise the best Clean Power technology available for reduced harmonic distortion (THDi < 5%) and improved control over high-efficiency motors to maximise your energy usage.

- Your selection and commissioning periods are shortened by engineering tools like the integrated web server and SINAMICS Startdrive.

- By integrating the drive system with TIA Portal, you may streamline processes and boost output.

Secure

- Thanks to User Management & Access Control and Security Integrated features, you can secure who has access to your automated operations.

- Your machines will meet the highest safety requirements thanks to Safety Integrated functionalities up to SIL 3 (Safety Integrated Level), PL e (Performance Level), and Category 4 in accordance with IEC 62061 and ISO 13849-1 standards.

- S2 System redundancy, IP55 protection, and 3C3 coating ensure that your system will always be available—even in challenging conditions.

Future-proof

- You may speed up time-to-market by designing, commissioning, and optimizing your application with the help of the digital twin.

- The diagnostics and cloud and edge monitoring increase the dependability of your system.

- Your ability to adapt to changing market demands is enhanced by a seamless system portfolio, hardware, and software options.

How to overcome the difficulties in motion control today

The Siemens Xcelerator line now includes SINAMICS G220 drives, the first SINAMICS drives. As such, especially with relation to digitization, it is made to address a range of issues and provide new opportunities.

Effective choice and simple commissioning

Because the drive system has an integrated web server, it can be easily configured, quickly diagnosed, and maintained from a variety of smart devices, including a phone, tablet, and laptop. Additionally, Startdrive TIA Portal fully integrates SINAMICS G220, cutting down on commissioning time.

The multifunctional motor

Flexible hardware and software options enable SINAMICS G220, designed for a wide range of sectors and demands, to meet your unique requirements.

Highlights

- With the optional IIoT module, increase transparency by allowing the drive and Industrial Edge to exchange high frequency data.

- Utilise SINAMICS software tools such as Safety Extended and Motor Control Extended to enhance the performance of your apps.

The drive with low harmonics

SINAMICS G220 Clean Power, which has an integrated Active Infeed Unit, lowers line harmonics. Usually, the overall harmonic distortion is limited at less than 5%.

Highlights

- Lower system losses in transformers and cables to enable up to 100% utilisation.

- Avoid harmonics with the main connection.

- Increase the lifespan of machinery and motors by maintaining a steady output voltage.

System Overview

laying the foundation for energy-efficient and sustainable propulsion systems

Future industries will be productive, efficient, and sustainable. Your manufacturing will be more energy and environmentally friendly with our innovative driving systems and digital services.

- Make wise decisions to further your sustainability objectives: Siemens has introduced the Siemens EcoTech logo to facilitate easier purchasing decisions. It is an environmental statement for our products derived from product-specific analyses of pertinent KPIs related to sustainability.

- Save time and resources: By simulating and virtualizing the drive system, you can save time and resources during the design process with the help of the digital twin in TIA Portal and SINAMICS DriveSim Advanced.

- Reduce harmonics: Clean Power technology enables a more effective and sustainable driving system by reducing line harmonics to the lowest possible level (THDi 5%) via the integrated infeed unit.

- Lower energy consumption: With SINAMICS Drive Software, you benefit from energy-saving functions and best-in-class motor control.

- Enhance transparency: With Analyse My Drives Edge, you can analyze the drive train and application data to enable efficiency in the optimization phase.

- Detailed life cycle analysis: With the Environmental Product Declaration (EPD), you will be able to analyse the life cycle of your drive system.

- Save tons of paper: With ID-Link, you can scan the QR code on our drive to obtain all relevant information such as technical data, certificates, manuals and much more.

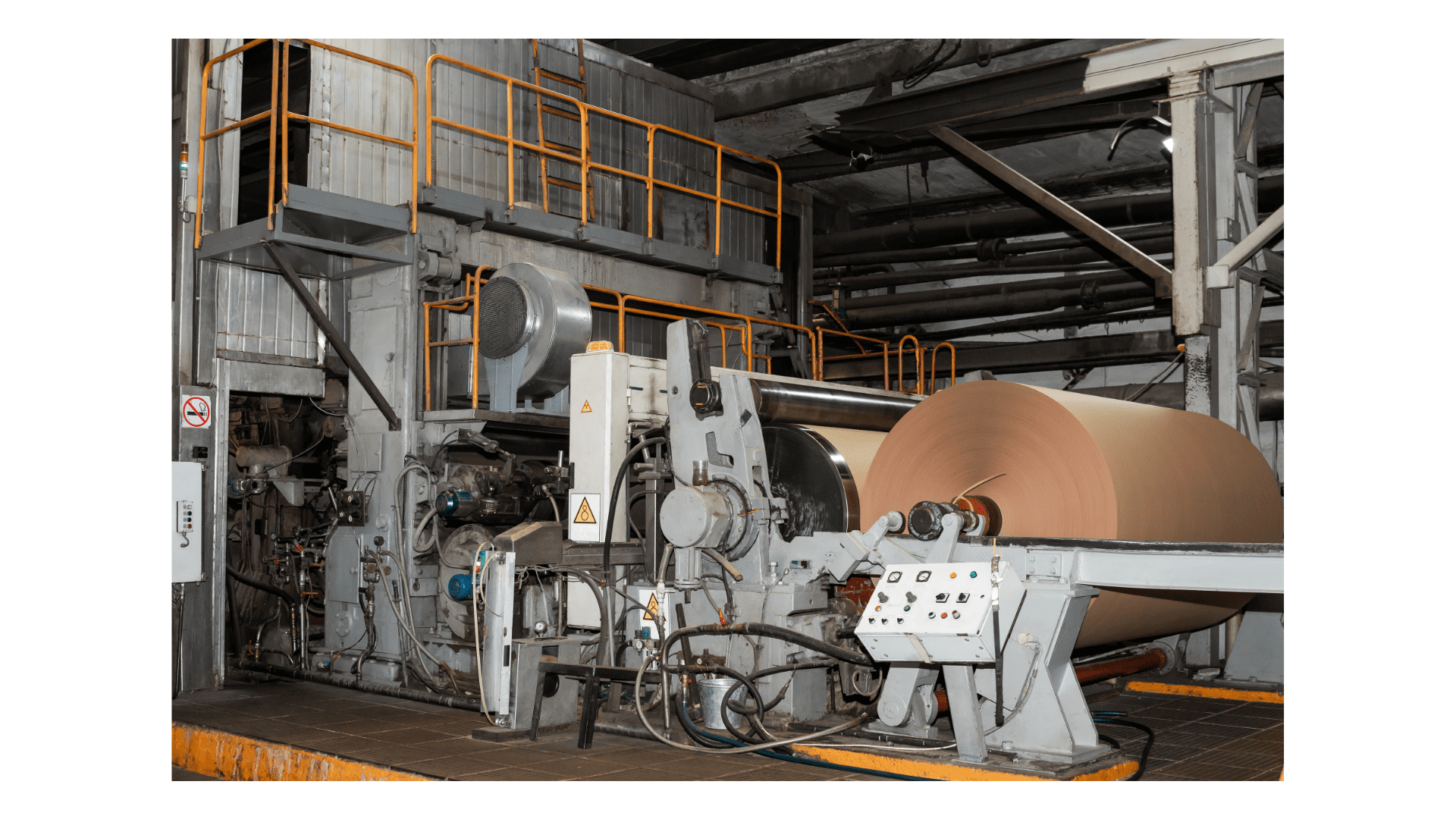

Ideal for all sectors

SINAMICS G220 is a feature-rich modular frequency drive that can be used in a wide range of industries, but it is particularly well-suited for the food and beverage, chemical, pharmaceutical, oil and gas, and maritime sectors.

In all sectors

SINAMICS G220 can be used in moving, processing, pumping, ventilating, compressing, and positioning applications and meet even the most demanding needs because of its extensive feature set and creative design.

Food and Drink

- Maximum flexibility: The food and beverage sector is characterised by the unique needs of each customer. These needs can be swiftly and simply satisfied with SINAMICS G220 by adding the required hardware option or software feature.

- Standardisation: The food and beverage (F&B) business is a very varied one, with a wide range of applications such as centrifuges, spray dryers, and mixers deployed throughout many nations. Manufacturers can standardise their factories globally using SINAMICS G220 since it complies with international rules and standards.

Pharmaceutical

• High adaptability: SINAMICS G220 can keep up with the fast-paced environment of the pharmaceutical industry. It is an ideal fit for the industry since it is a versatile drive system.

• Enhanced availability: The SINAMICS G220’s S2 redundancy, sturdy IP55 design, and 3C3 coating, which are appropriate for hostile situations, ensure the system’s availability. The integrated cyber security features of SINAMICS G220 protect user access to the automation process while maintaining the security of your data.

Chemicals

- Safe in all settings: Even in the most taxing circumstances, machines must operate dependably and safely. The chemical sector is a perfect fit for SINAMICS G220 because of its 3C3 coating and IP55 high level of protection. More dependability can be achieved by supporting S2 redundancy with SINAMICS G220.

- Possibility of optimisation: Utilising resources as efficiently as possible is more important than ever in these times of resource scarcity and growing expenses. More transparency is available with SINAMICS G220, which gives you meaningful data for process analysis and optimisation.

Oil & Gas

- Reduced costs: Since a plant’s continuous throughput is used to gauge its efficiency, any malfunction incurs large downtime expenses. By guaranteeing the availability of machines and systems with integrated webservers for quick diagnostics and maintenance via various customers, SINAMICS G220 lowers these losses.

- High degree of safety: In order to protect people and plants in hostile situations, the oil and gas business requires extensive machine safety. SINAMICS G220 can meet even the most demanding requirements because of the OM-SMT option module, which guarantees safe motor temperature for ATEX applications with an ATEX certified motor protection, and the Safety Integrated Extended software licence SIL3 / PLe.

Marine

- Less harmonics and emissions: The marine industry aims to reduce its carbon footprint, which means that applications need to be as energy efficient as possible. In addition, harmonics must be limited to a minimum, especially in an island grid. With SINAMICS G220 Clean Power, both goals can be achieved.

- High level of protection: To guarantee the availability of all systems and applications, all components must be extremely robust. Thanks to IP55 protection and 3C3 coating on the electronics, SINAMICS G220 is ideally suited for the marine industry.

Suitable for a variety of applications

Moving

The drive for both basic and extremely dynamic conveyor belts and stacker cranes is Moving SINAMICS G220.

Processing

The drive for continuous operations with high speed and torque accuracy is SINAMICS G220.

Pumping

SINAMICS G220 is suitable for pumping, ventilating, and compressing applications.

Positioning

SINAMICS G220 is the drive for the positioning of individual or multiple coordinated axes.

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.