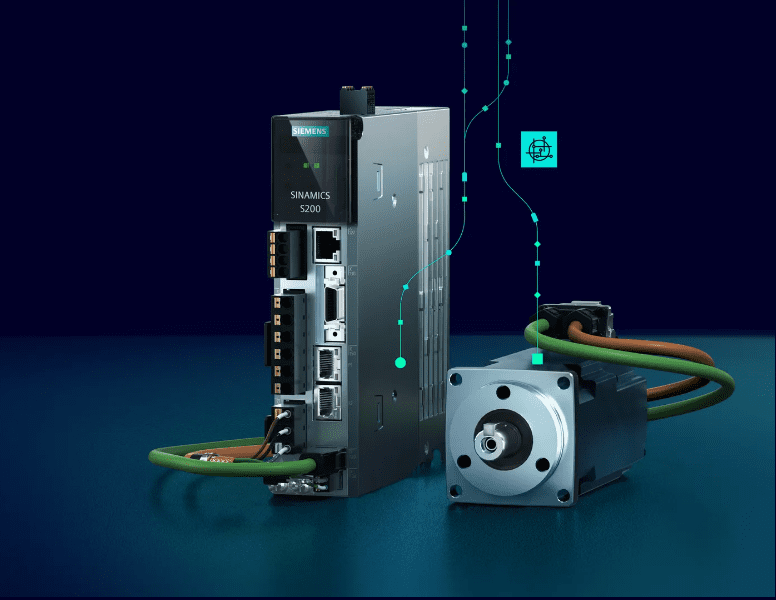

Drive System SINAMICS S200 Servo

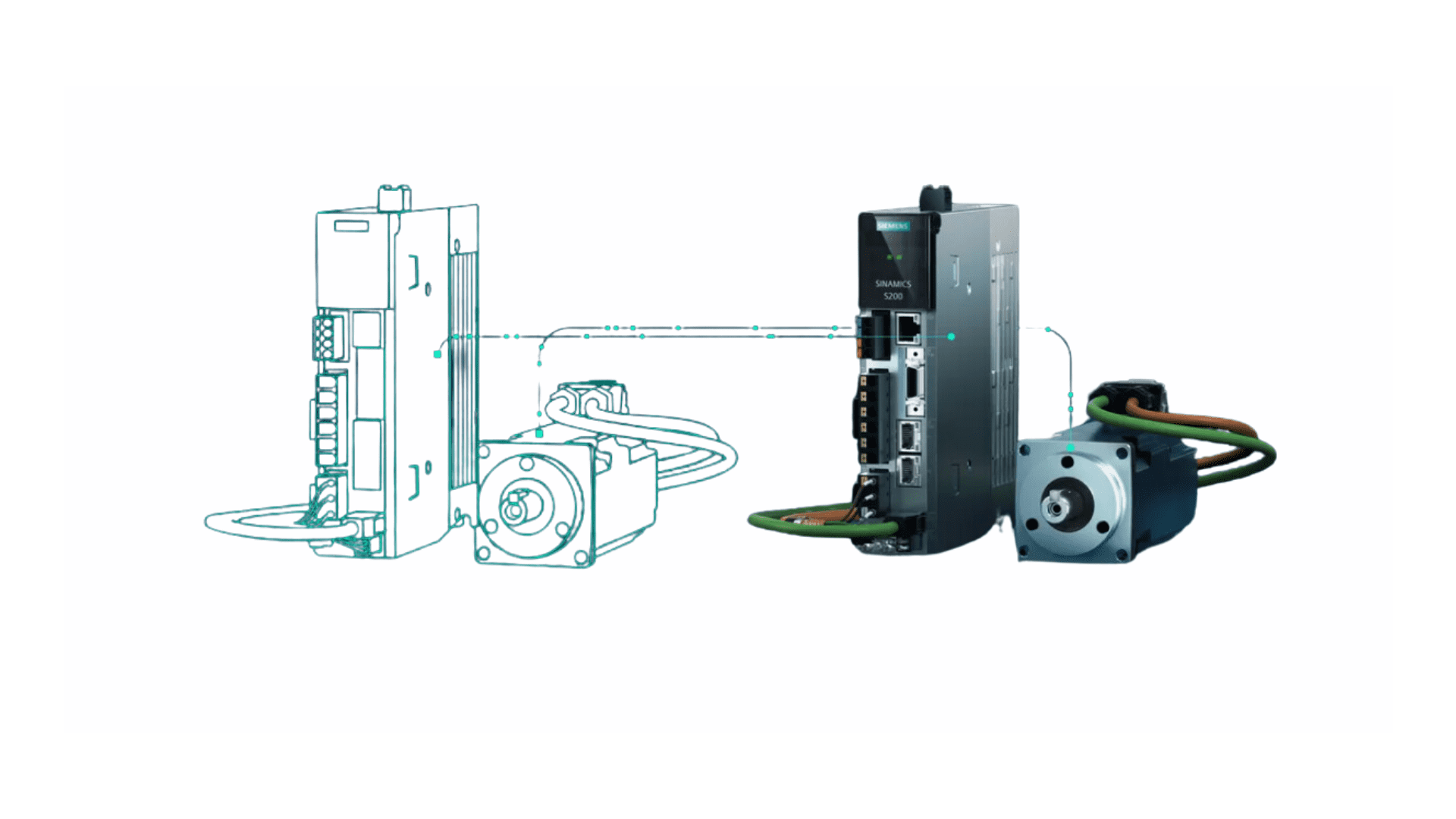

Enjoy an effective and efficient system solution! Included in the system are Motion Connect cables, a SIMOTICS S-1FL2 servo motor, and a SINAMICS S200 servo drive. A wide range of common applications can be addressed by this system, which has been specifically built with a power range of 0.1kW to 7kW and multiple communication options including PROFINET IRT and pulse train

Servo On! Move Beyond.

In the ever-evolving market of today, we always strive to strike the ideal balance between increased productivity and enhanced efficiency at a reduced cost. The SINAMICS S200 servo drive system, the newest member of the SINAMICS family, excels in this situation.

Performance optimized

- Response optimized with fast current controller cycle as well as PROFINET IRT communication to controllers

- Power optimized with up to 350% overload capacity

- Precision optimized with up to 21 bits high-resolution encoder

Easy to use

- Reduced space requirement thanks to the compact system design

- Easy control with integrated holding brake control and brake resistor

- Easy engineering via Webserver and SINAMICS Startdrive

- Easy implementation with global standards and certifications

Fit for future

- Fit for your applications via flexible hardware solutions and complete TIA offering

- Fit for digitalization on machine simulation with SINAMICS DriveSim.

- Fit for your security needs by providing reliable protection and secure access to your automation processes.

Select your ideal system step by step

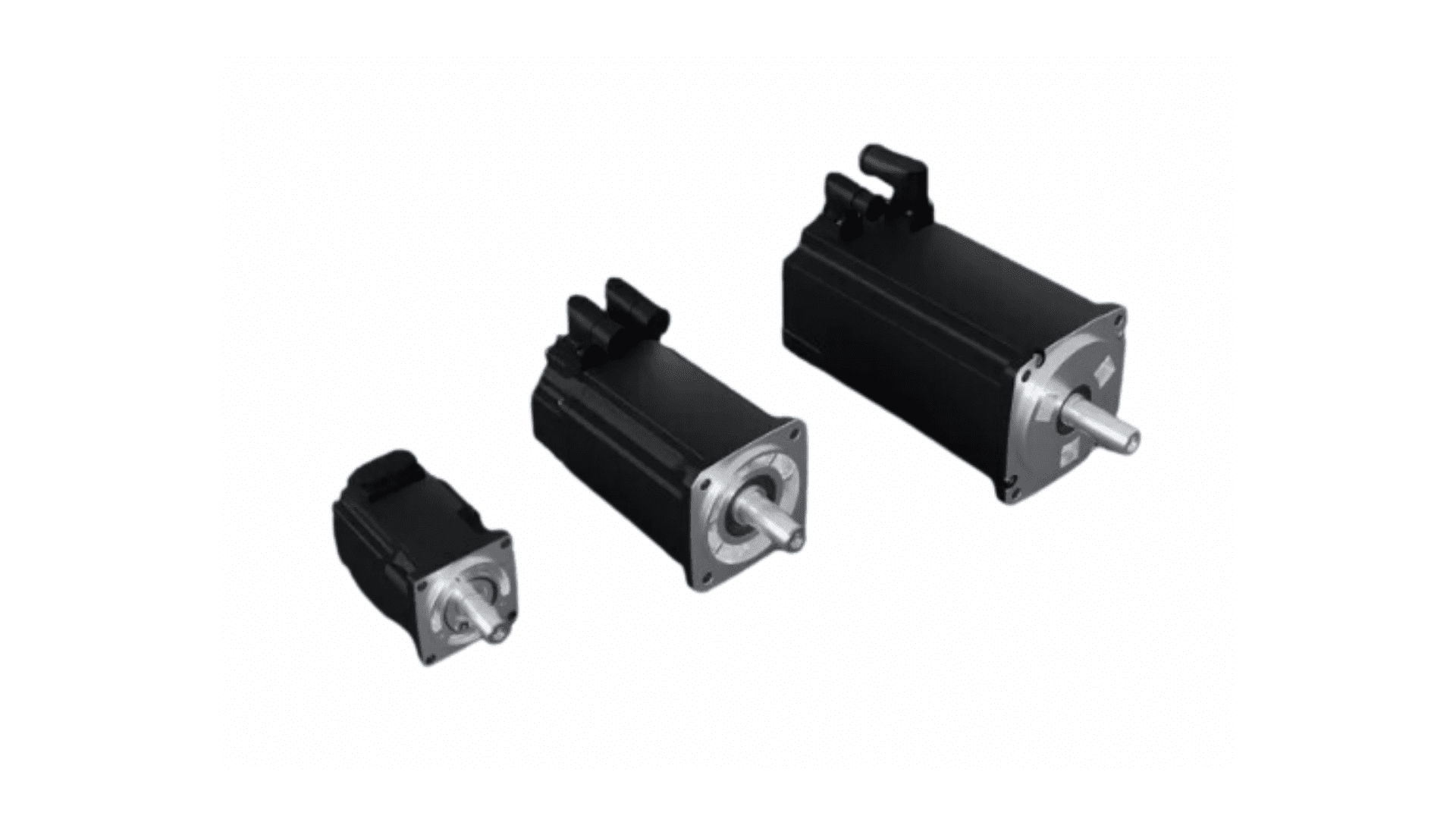

Step 1: Select the dynamic servomotor

SIMOTICS S-1FL2 exhibiting dynamic functionality

Get precise performance from the servo motors SIMOTICS S-1FL2. It responds to minuscule variations in speed or position and has a high-resolution encoder with up to 21 bits, which guarantees accurate and seamless control in typical applications. It assists users in lowering maintenance expenses and increasing productivity thanks to its battery-free design.

- Low inertia servo motors

- Medium inertia servo motors

- High inertia servo motors

Advantages

- High dynamic via ultra rotor inertia

- Maximum speed up to 6500rpm

- Help increase productivity with up to 350% overload capacity

- Reduced space requirement thanks to reduced motor length

Step 2: Select the optimal servo drive

SINAMICS S200 with optimized performance and options for versatility

It’s easy to include the servo drive into your current setup. It comes in two versions: basic and standard, and it integrates flawlessly with SIMATIC controllers. Standard version has communication types such as PROFINET RT/IRT (PN) or Pulse train (PTI) to fulfil different application needs.

Advantages

- Fast current controller with cycle time of 125µs (PN).

- Fast communication via PROFINET IRT

- 8KHz PWM frequency for reliable operation

- Reduced space requirement thanks to compact system design

- Optimized cost with Integrated brake resistor and holding brake control

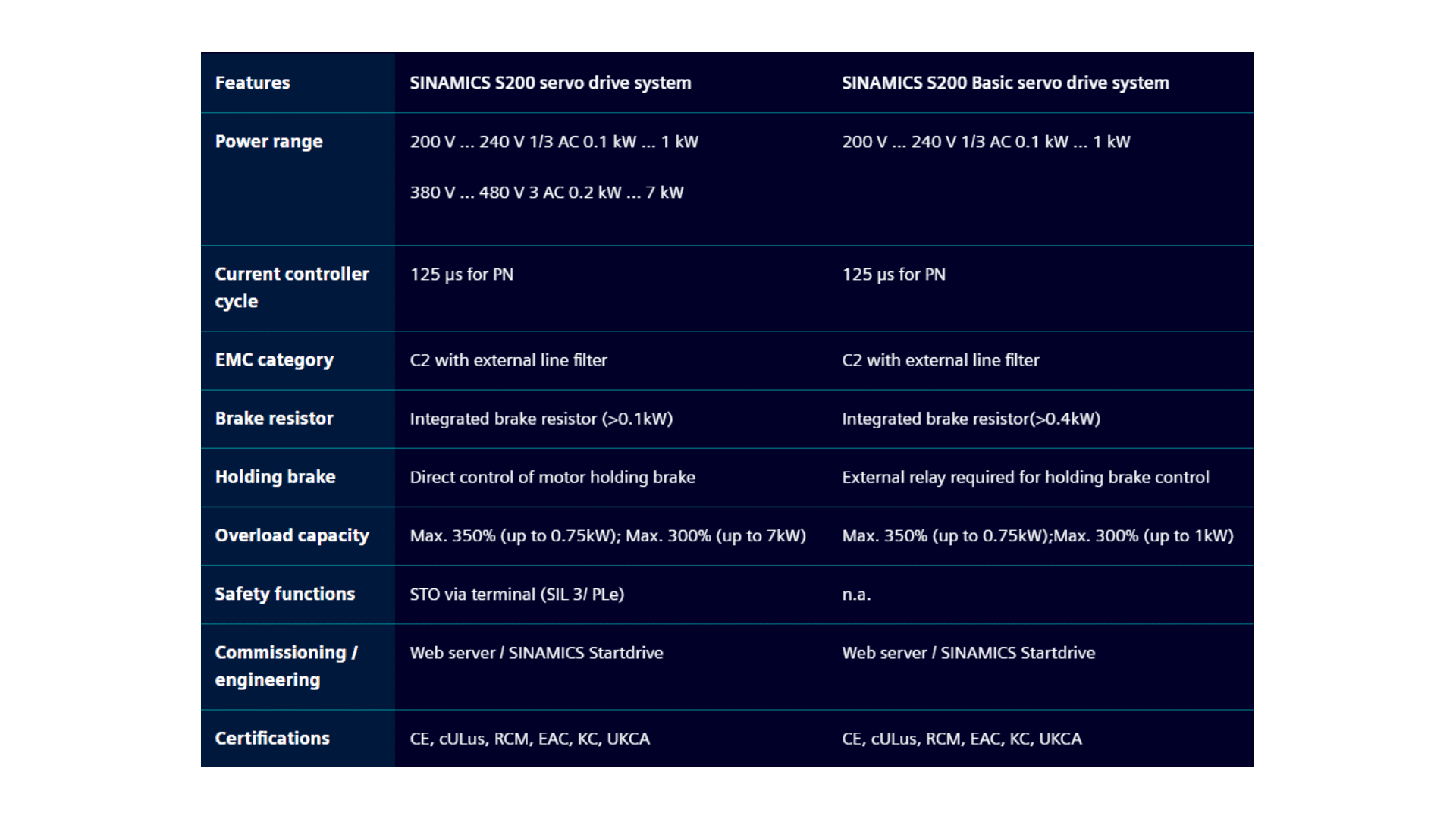

SINAMICS S200 servo drive

Equipped with a wide variety of functions that make it perfect for standard applications.

- Power rating:

1/3AC 200V 0.1- 1kW

3AC 400V 0.2- 7kW - STO via terminal (SIL3 / PLe)

- Integrated brake resistor (>0.1kW)

- Direct control of motor holding brake

SINAMICS S200 Basic servo drive

Designed for entry-level basic applications

- Power rating:

1/3AC 200V 0.1 -1kW - Integrated brake resistor (>0.4kW)

- External relay required for holding brake control

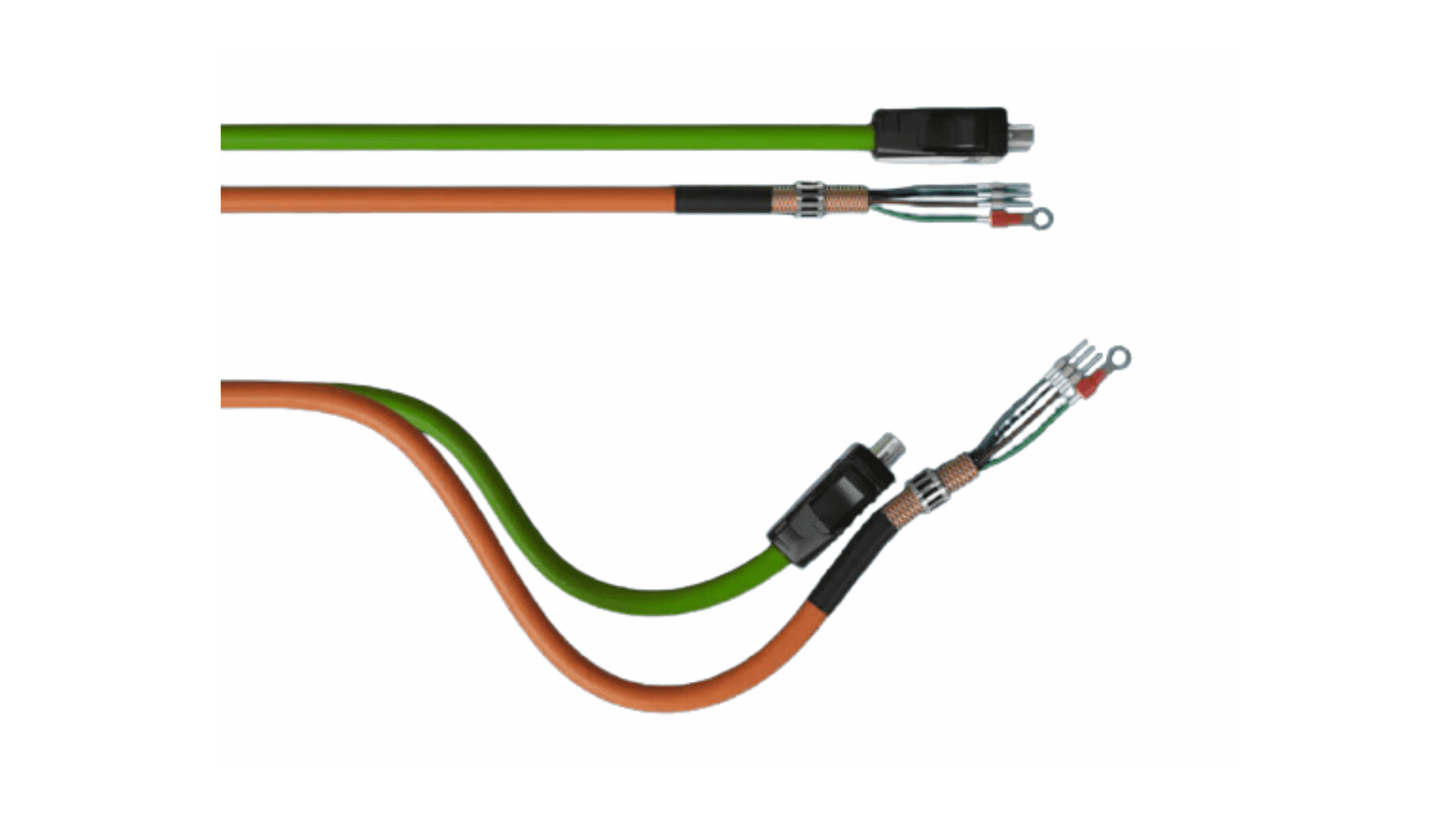

Step 3: Select the matching cables

MOTION-CONNECT 350 and 380 for ease of use

It’s easy to include the servo drive into your current setup. It comes in two versions: basic and standard, and it integrates flawlessly with SIMATIC controllers. Standard version has communication types such as PROFINET RT/IRT (PN) or Pulse train (PTI) to fulfil different application needs.

- Standard cables

- Flexible cables

Advantages

- Easy installation with one-push-lock connection technology

- Effective connectivity thanks to hybrid connector, which brings power, encoder and brake connection together

- Length is up to 30 meters without extension cables needed

Step 4: Select the suitable controller

As a scalable system easily adapted to your needs

From the SIMATIC controller to the SINAMICS servo drives and SIMOTICS servo motors, the motion control system is optimally coordinated to meet diverse motion control requirements.

- SIMATIC S7-1200

- SIMATIC S7-1500/T

- ET200SP Open controller

- SIMOTION

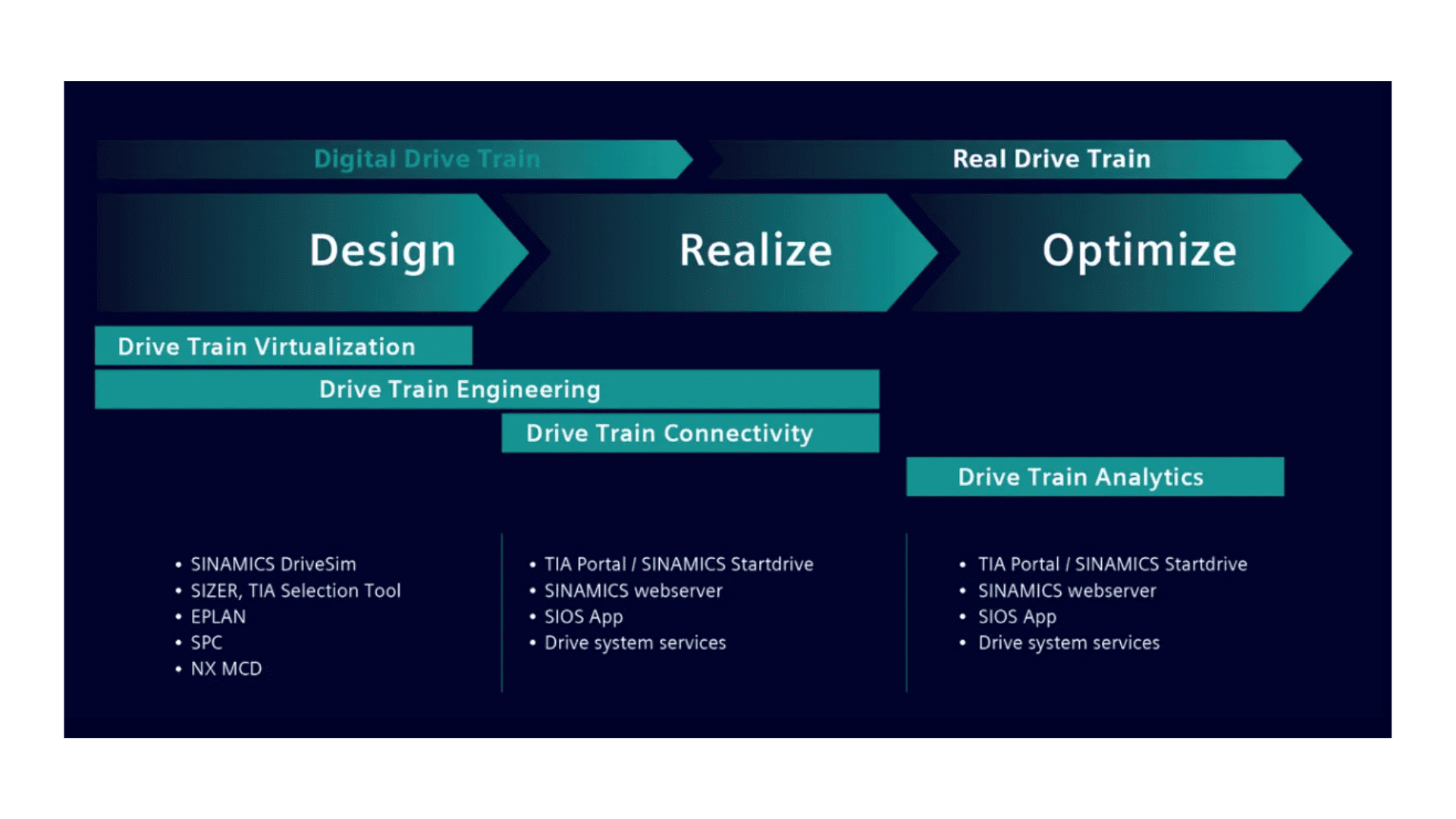

Digital engineering journey

Increasing the impact of sustainability

Future industries will be productive, efficient, and sustainable. Your manufacturing will be more resource- and energy-efficient as well as ecologically friendly with our motor systems and digital solutions.

- Make informed choices to support your sustainability goals: to help make your buying decision easier, Siemens introduces Siemens EcoTech label. It is an environmental declaration for our products based on product-specific evaluations of sustainability relevant KPIs.

- Detailed life cycle analysis: With the Environmental Product Declaration (EPD), you will be able to analyze the life cycle of your drive system.

- Save time and resources: With the digital twin in DriveSim Designer, you can save time and resources in the design phase by simulating and virtualizing the drive system.

- Save tons of paper: With ID-Link, you can scan the QR code on our drive to obtain all relevant information such as technical data, certificates, manuals and much more.

Technical overview

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.