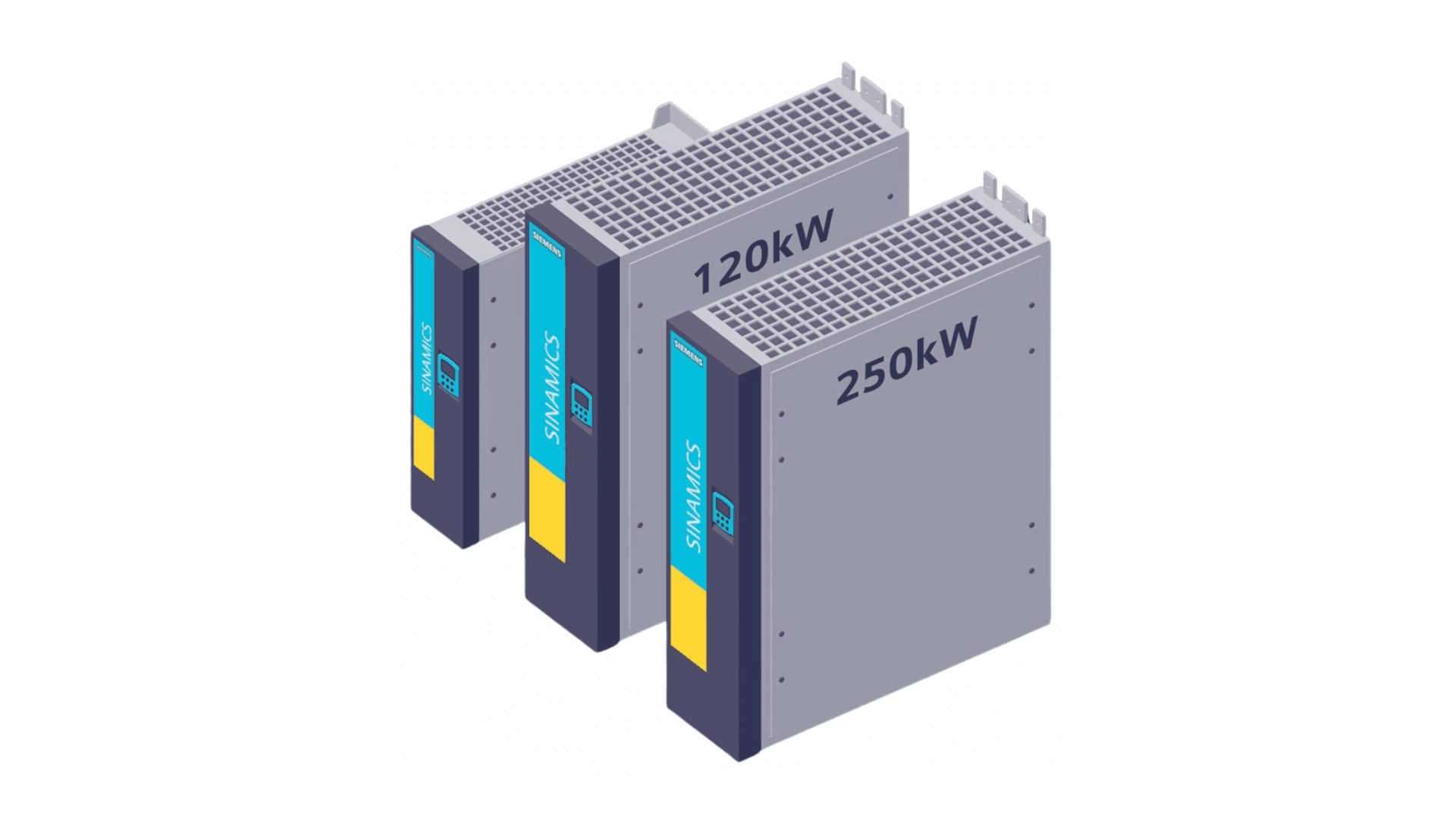

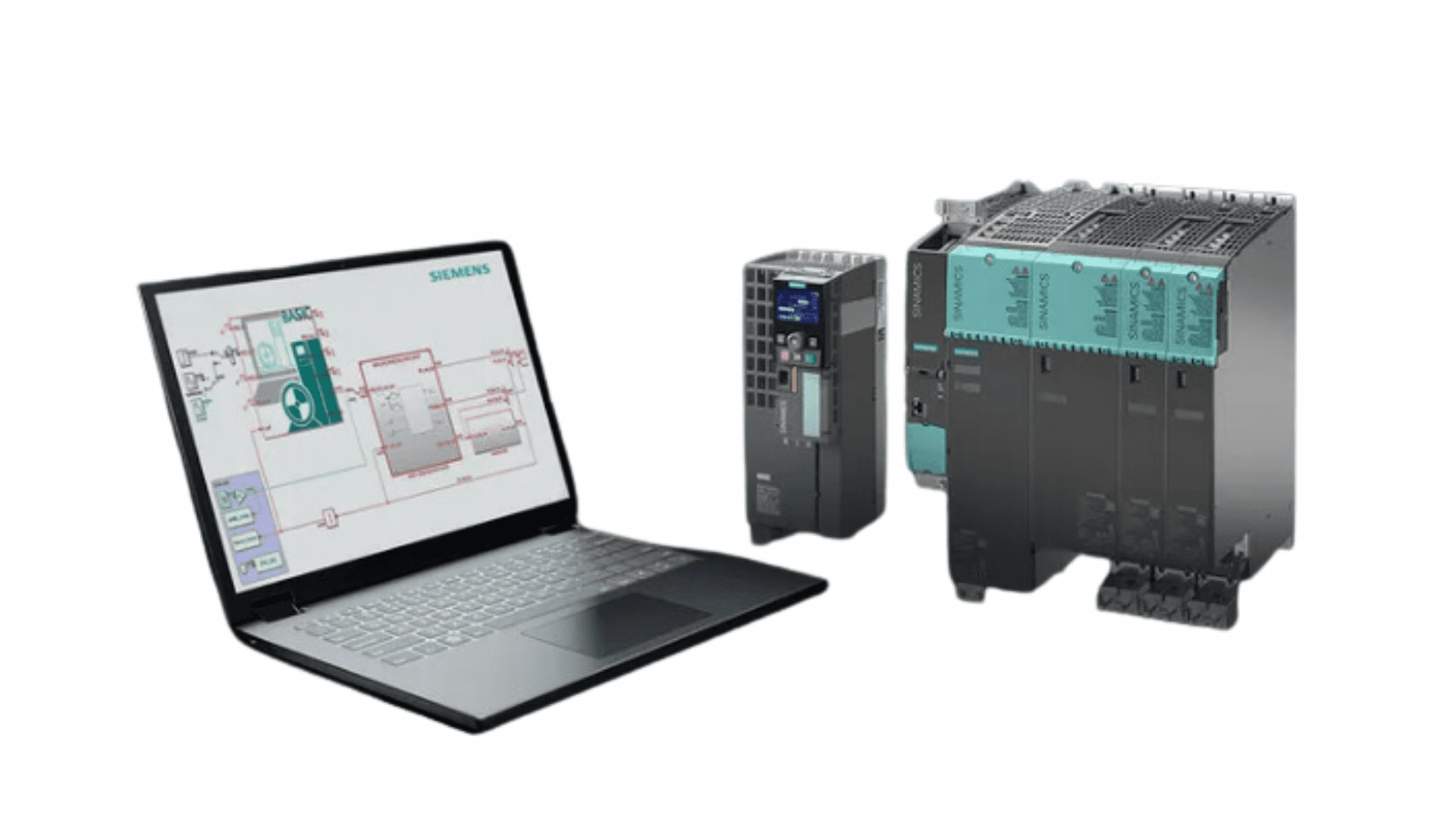

the flexible and high-performance drive system

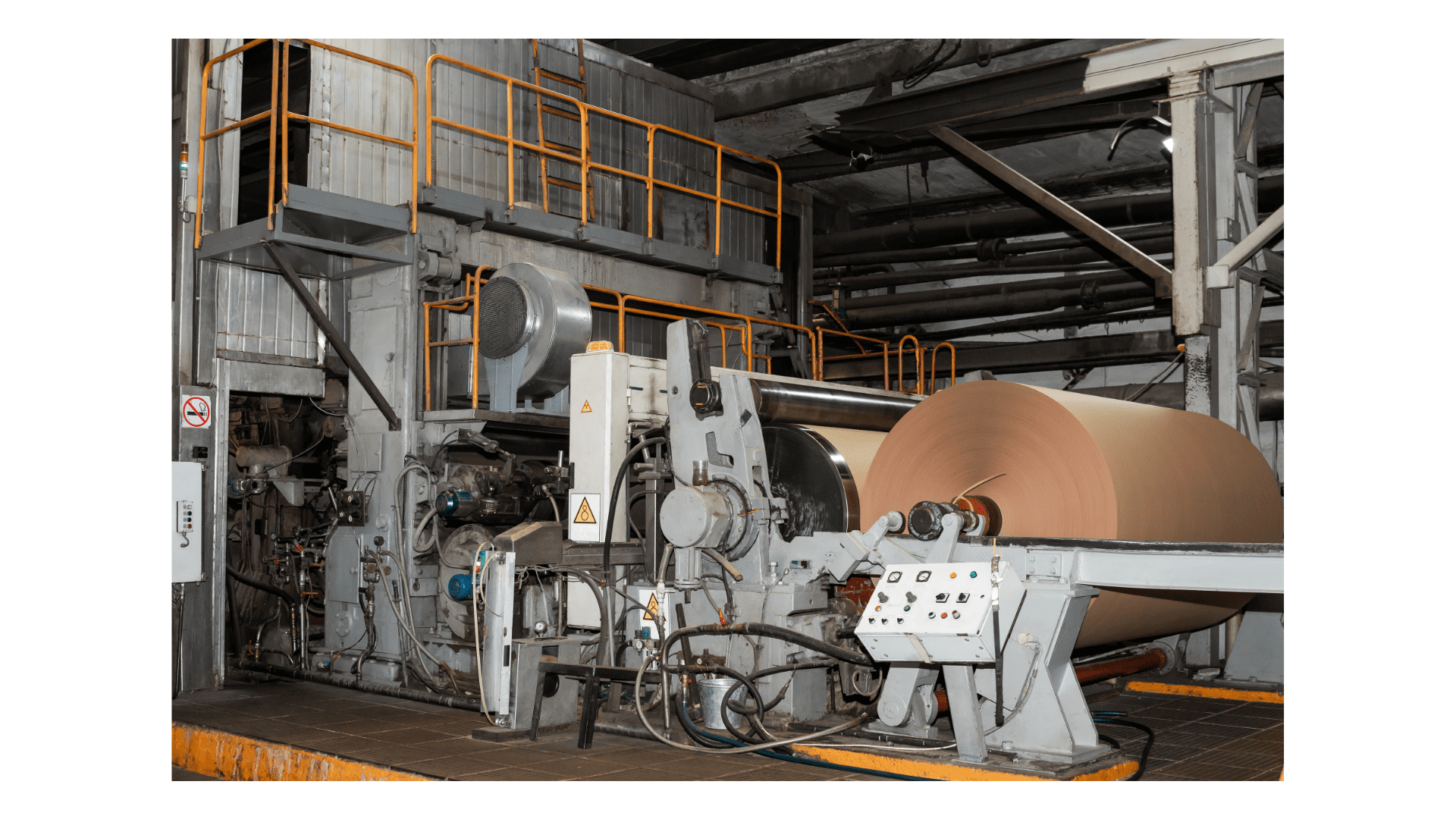

You are choosing a system that provides the best performance, productivity, and flexibility when you choose SINAMICS S120. You may quickly and easily configure the drive system that best suits your needs with this modular system, and that’s true for practically any drive application.

Universal. Precise. Safe.

Universal

- SINAMICS S120 allows power and closed-loop control performance to be freely combined

- Greater flexibility with central closed-loop control intelligence

- Performance for vector and servo control can be freely selected

Precise

- Lower life cycle costs when operating plants and systems

- All components can be parameterized, programmed and commissioned with the Totally Integrated Automation (TIA) engineering platform without any system discontinuities

- The functions are predominantly implemented using a comprehensive range of embedded software

Safe

- Universal, standardized safety concept – Safety Integrated

- Integrated safety functions: STO, SBC, SS1, SS2, SOS, SLS, SDI, SSM, SLP, SP, SBT

- Seamless implementation of safety functions in accordance with SIL 2 (EN 61508) and PL d (EN ISO 13849-1)

Efficient diagnostics and maintenance – at any time from any place

With the SINAMICS web server, you may use any web-capable device to access your SINAMICS S120, no matter where you are at the moment. You can cut expenses and overhead by employing the SINAMICS web server for diagnostics, maintenance, or integrating your own webpages.

High efficiency

- Fast overview about the current configuration and condition of the drive

- Diagnostic information and messages are displayed in easy to understand plain text and in several languages

- The device functionality can be updated from any network-compatible PC (locally or by remote access)

- Fast and simple overview of helpful links to support troubleshooting

Highest flexibility

- Parameter lists defined by the user are displayed

Parameter lists can be created, managed and deleted

Cross-axis parameter lists all possible - Users with various rights can be configured

- There is no dependency on the commissioning tool (Starter/Startdrive)

High degree of user-friendliness

- English, German, Chinese, Italian, French, Spanish

- Machine documentation can be archived

- Your own logbooks can be directly saved in the drive (information can be simply exchange between service and maintenance)

In the realm of digital drives, SINAMICS S120

With digital drive data, you can jumpstart a productive future with greater transparency, efficiency, and simplicity as well as reduced effort, errors, and expenses.

TIA Selection Tool now incorporates SINAMICS S120

To facilitate speedy and transparent dimensioning and configuration, the SINAMICS S120 Booksize Active Line/ Motor Modules are first integrated into the TIA Selection Tool. This makes it simple for you to use application-specific criteria to define your automation and drive design, including control, motor, gear unit, and converter. After that, the Industry Mall gathers the necessary product lists and paperwork for your order.

Quick: Complete project configuration with just a few inputs

Easy: Technically always up-to-date about product portfolio and innovative approaches

Smart: Smart selection wizard for error-free configuration and ordering, pre-testing and simulating

“SINAMICS DriveSim Basic” simulation

All SINAMICS S120 device types can be realistically simulated with the help of the virtualization solution “SINAMICS DriveSim Basic”; it requires little parameterization work and is simple to use.

The simulation tool imports a standardised “Functional Mockup Unit” (FMU) straight from source. Before the design stage, drive configurations in machines can be simulated, adjusted, and optimised using specific drive parameters and interfaces that are accessible. Unlike the actual product, the simulation simply lets you configure the drive’s functional portions. Time is saved, the planning process moves more quickly, and quality is raised.

By using “SINAMICS DriveSim Basic,” mechanical interaction, including virtual commissioning of the PLC, and control system testing and validation are made possible automatically.

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.