Innomotics XP explosion-proof low voltage motors

Low voltage motor Innomotics XP

Even in the worst of circumstances, our sturdy Innomotics XP low voltage motors operate for an incredibly long time and with perfect dependability—on both the mains and all available converters. Our Ex motor programme is finished, meeting all standards while operating with the highest level of efficiency and safety. We also provide double-protected drive solutions for special needs.

Meets and exceeds efficiency requirements

- IE3 efficiency for all motors

- IE4 ≥ 250 kW, Ex Ec, Ex tb/tc

- Highest System efficiencies (IES)

Simple and reliable Platform concept

- Harmonized motor selection for all variants

- Consistent performance values

- Simplified spare parts concept

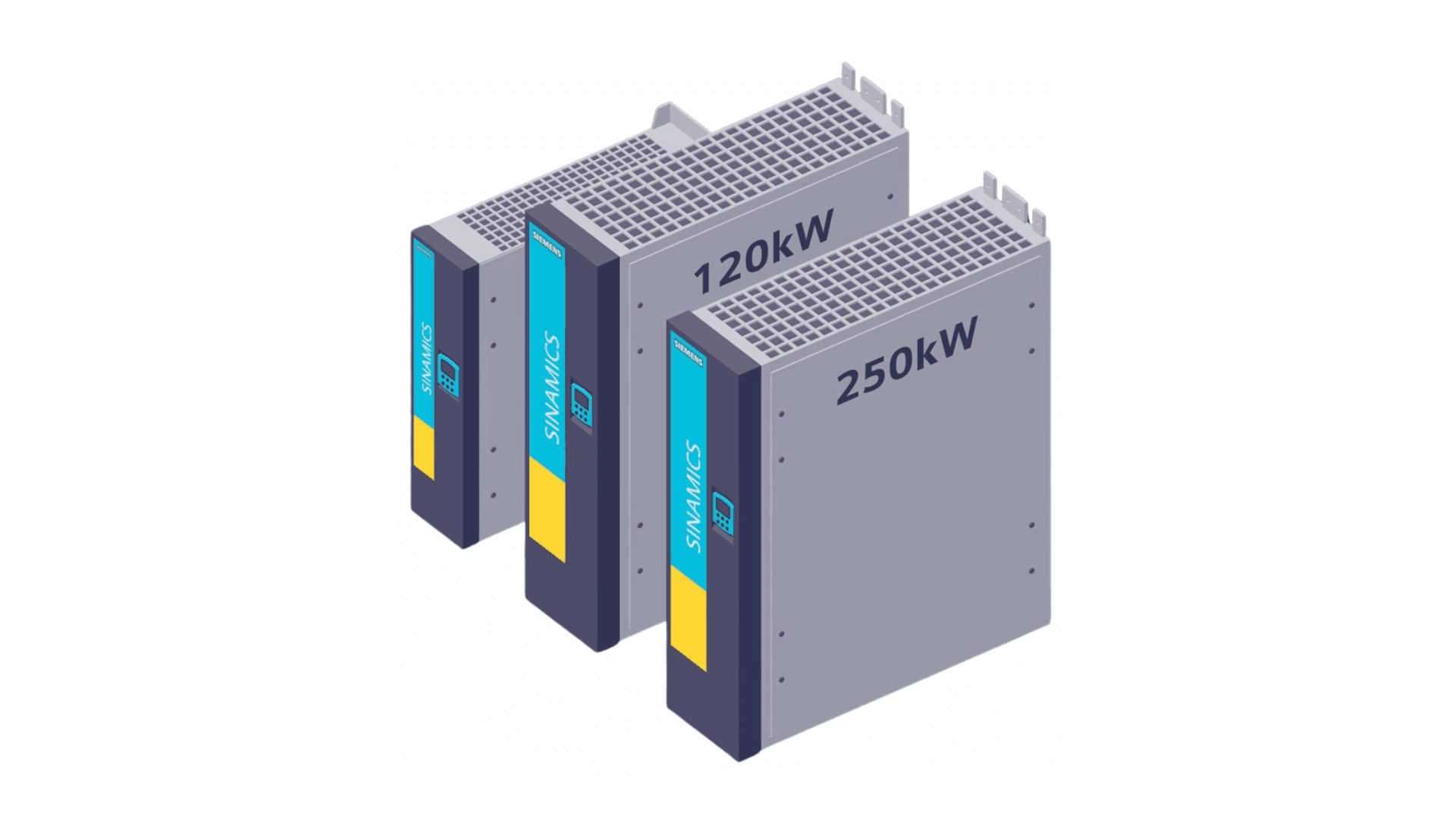

Converter operation with any converter

- Operation with Innomotics G / S series

- 3rd party PMW converters

- optionally up to 690V with and without filter

Accepted by leading end customers

- Specification fulfillment through a variety of optional designs

- Special series for starting current up to a maximum of 700% or 600%

Flameproof motors for all demands

- Version for gas group IIC (including hydrogen)

- Economic variant for applications in gas group IIB

- terminal boxes in Ex eb design, optionally in Ex db

smooth operation even at extreme temperatures

- Standard version from -20°C to 40°C

- Optional for high temperatures up to +60°C

- Optional for low temperatures down to -55°C without preheating

Global, Local and Marine Certificates

- Complete portfolio in ATEx and IECEx

- Country certificates for EAC, China, India

- Marine certificates DNV GL, BV, ABS etc.

Fits for aggressive atmospheres or offshore use

- Degrees of protection IP55 to IP66

- Coatings in corrosion protection class up to CX (25 years durability)

- Conductive coating for high electrostatic loads

solutions for your industry

Oil and gas

The driving technology employed in the oil and gas industry is subjected to tremendous demand. This is true regardless of the deployment location—offshore on the high seas, in the Arctic, or in the desert—and the severe explosion risk that is inherent in both commodities. This is taken into consideration in the Innomotics XP CHEMSTAR edition, which is specifically made for the oil and gas sector. Even in the harshest circumstances associated with the production and transportation of oil and gas, the motors’ basic and extra characteristics are integrated to minimize lifetime costs and maximize plant availability and safety.

Chemical industry

In the chemical industry, flammable liquids, gases, and solids undergo a range of frequently intricate conversion and processing steps. Many distinct plant components carry the risk of exploding, for instance, because flammable solvents are present or because certain labour procedures may result in the creation of so-called hybrid combinations. These have low minimum ignition energy and contain both potentially explosive gas and dust. It follows that the motor must run consistently and effectively even in chemically hostile environments. Maximum dependability and safety are guaranteed by the motor’s precise customization to these environmental conditions in the Innomotics XP CHEMSTAR variant, which was created especially for the chemical industry.

Fit for use on the high seas – Marine certificates for flameproof Innomotics XP

Working on the high seas can be dangerous. These include platforms used for offshore drilling and production, oil tankers, explosive chemicals, and liquid natural gas (LNG), where extra care must be taken. On such ships or platforms, the list of dangerous places where motors are used, both above and below deck, is extensive.

The major propulsion systems, bow thrusters, azimuth drives, compressors, and other pumps and fans are located below deck. Places above deck that pose a risk include deep-well pumps, winches, cranes, and boosters. Maximum safety is ensured in each of these sites by Innomotics XP motors housed in explosion-proof enclosures; their suitability for marine applications is further supported by the following significant international marine certification:

- LR – Lloyds Register (UK)

- DNV GL – Det Norske Veritas / Germanischer Lloyd (Norway / Germany)

- BV – Bureau Veritas (France)

- RINA – Registro Italiano Navale (Italy)

- ABS – American Bureau of Shipping (USA)

- KR – Korean Register of Shipping

Foodstuffs – reliable protection, even when there’s dust around

Fine dusts can cause hazardous explosions in silos, mills, and conveyor systems in some parts of the food business. For example, flour dust explosion is thought to be especially hazardous while processing grains and making bread. Ex tb and Ex tc dust explosion protection for our Innomotics XP motors are specifically designed to withstand these dangerous circumstances. Their dust-tight container, which is IP65 certified for Zone 21, keeps important dust accumulations inside. Their enclosing surface temperatures are restricted to the point where they cannot ignite the dusty atmosphere around them. The Innomotics XP’s ventilation system is also intended to make sure that sparks never happen. Any electrostatic charge or discharge is successfully prevented by specially conductive paint finishes.

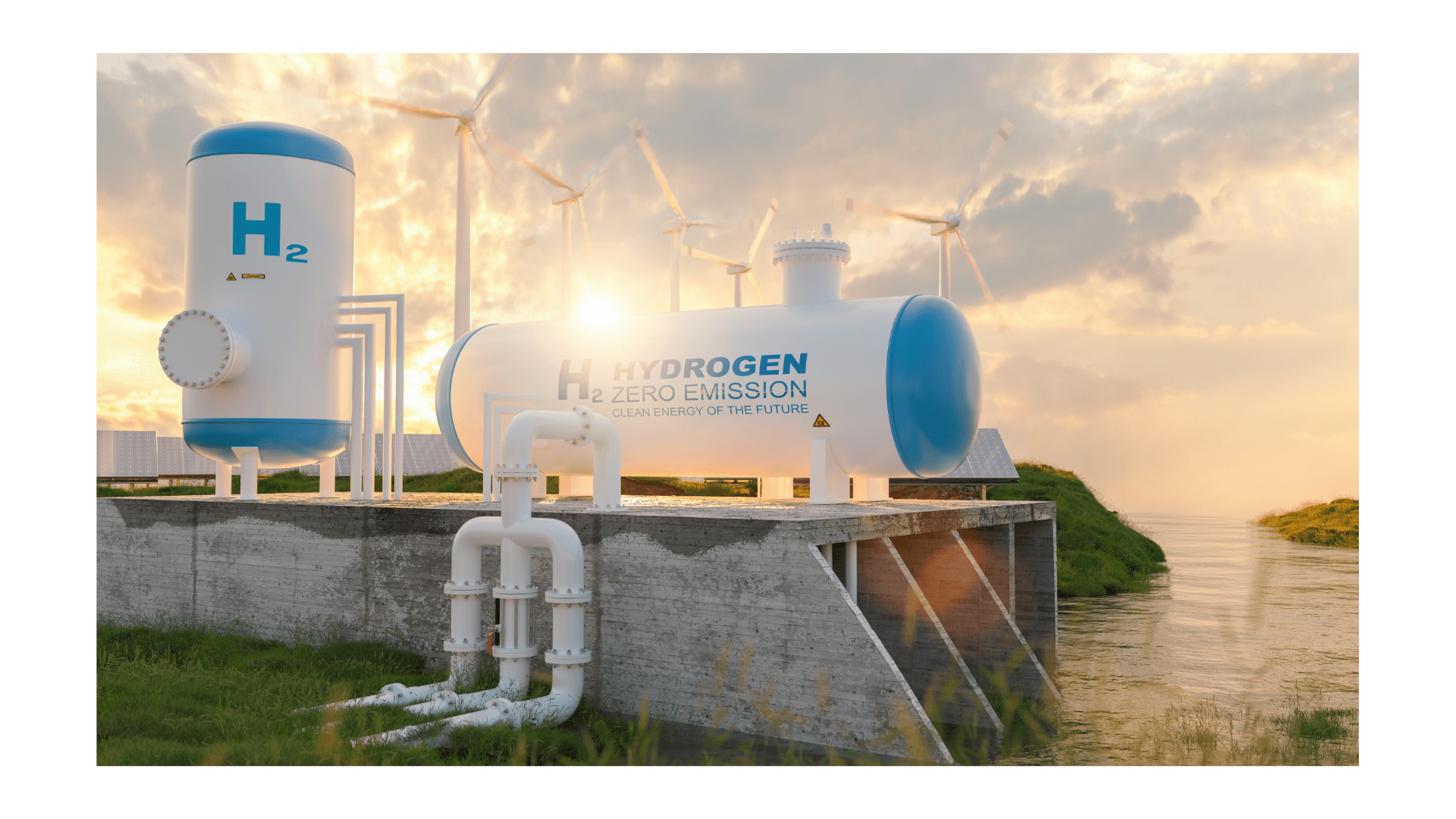

Predestined for the hydrogen industries – Innomotics XP motors for Ex-Zone 1 gas group II C

Since the hydrogen industry works with one of the most explosive gases ever, explosion protection is especially crucial. This also holds true for the motors, which are utilised in every stage of the process—from production to storage and transportation to final use. Auxiliary drives, heat exchangers, and compressors utilised in several process steps are examples of typical applications. We provide Innomotics XP motors, which are intended for gas group IIC and have a concept that has been proven thousands of times over in the processing and handling of extremely explosive gases, for all drive applications along the hydrogen value chain.

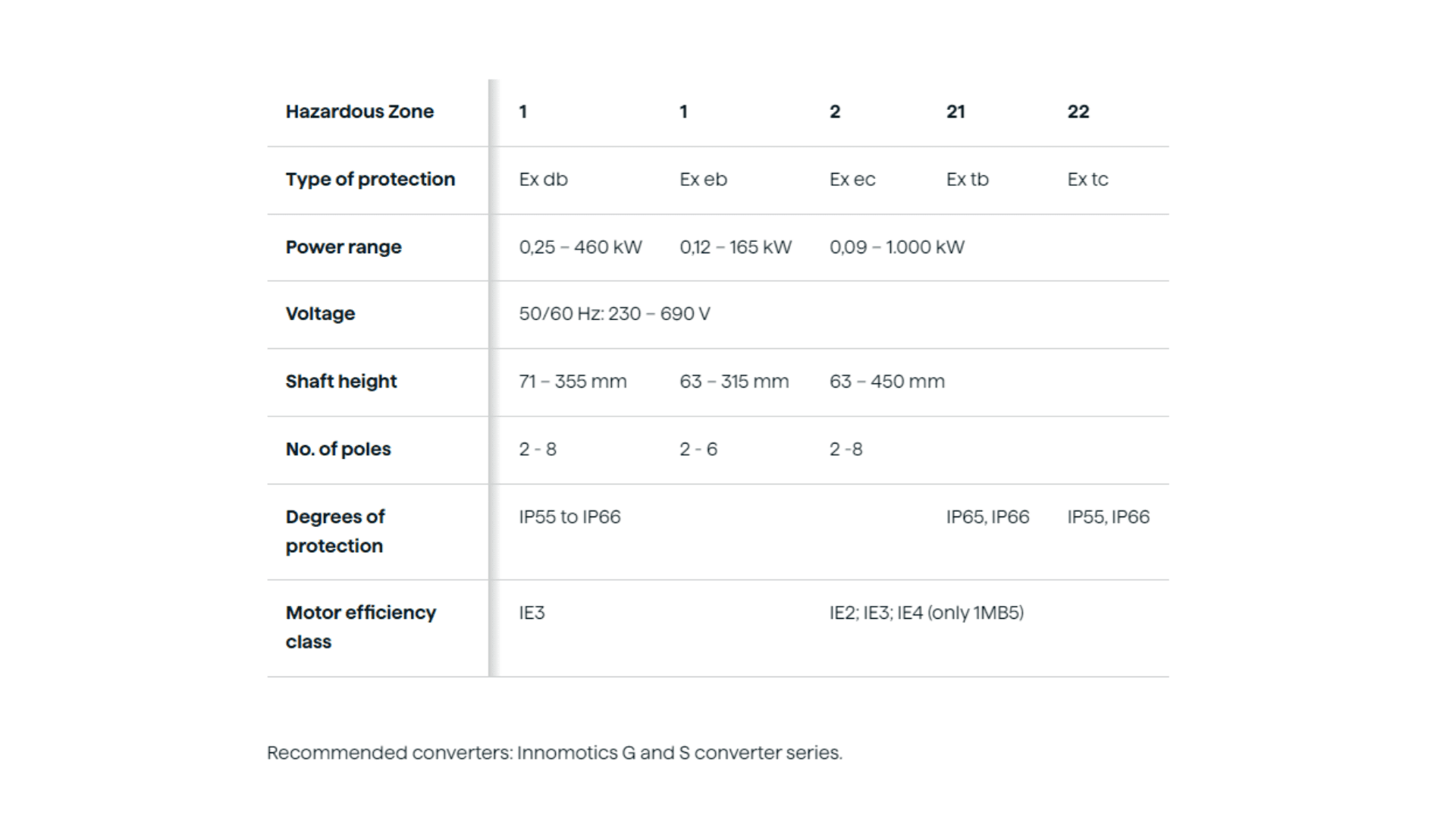

For pump and fan application we recommend our Innomotics XP motor in type of protection increased safety Ex eb. The technical and price economically optimized motor concept for the chemical industry fits best for or direct on-line (DOL) applications in outputs from 0.25 to 165 kW.

Motors with flameproof Ex db IIC protection are optional and work well for compressor applications as well as pumps and fans. They are the best in class when used with any frequency converter in the power range of 0.09 to 460kW, and they can be used on the mains or alternatively.

We can satisfy the preset needs of the hydrogen industry by combining our chemical industry-specific solution, Innomotics XP CHEMSTAR, with it.

Explosion protection and potentially explosive zones

Things to know about potentially explosive working environments, which aspects must be taken into account in a risk assessment, and into which zones potentially explosive areas can be divided.

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.