SD Severe duty motors

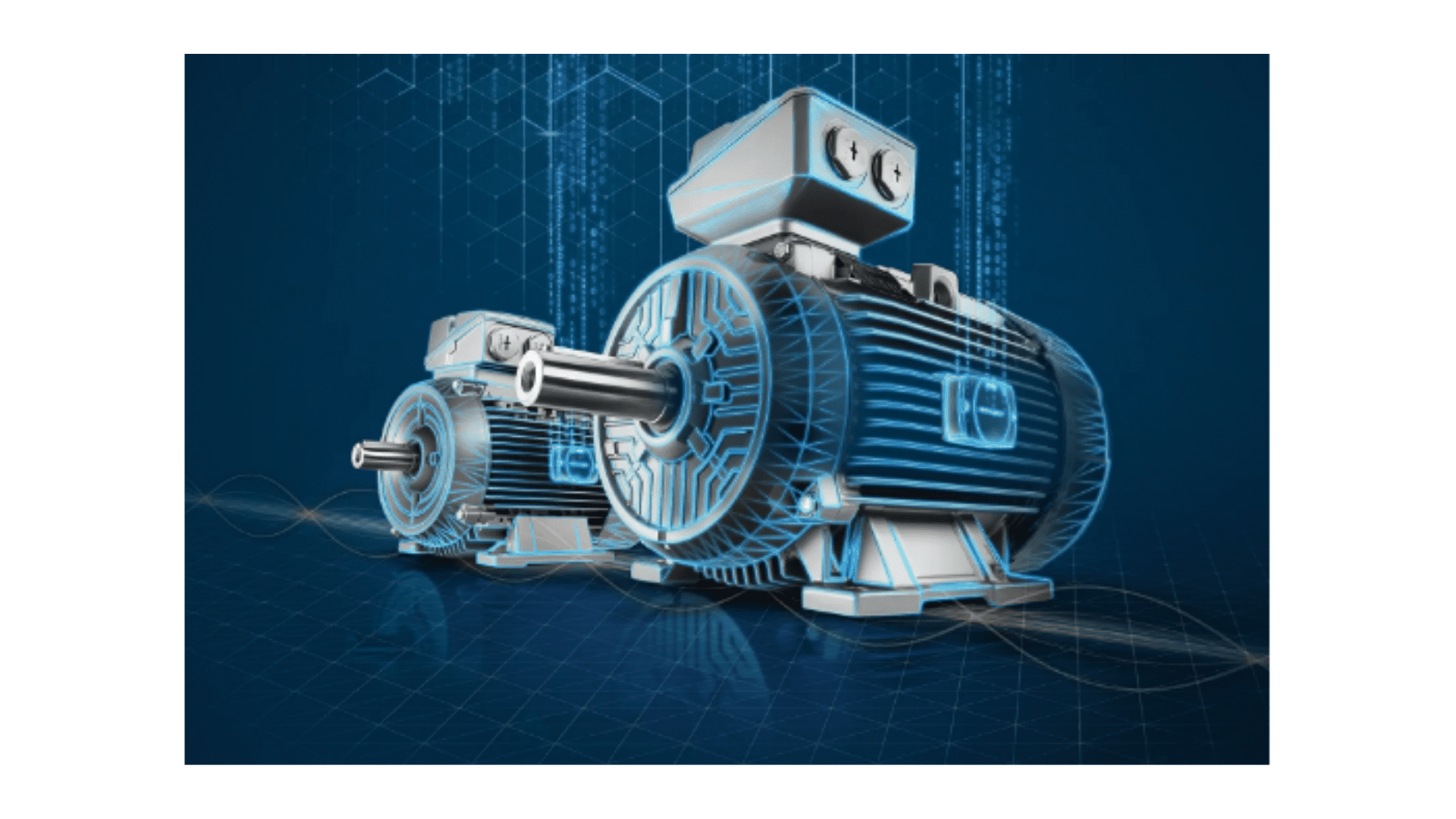

Innomotics SD low-voltage motor

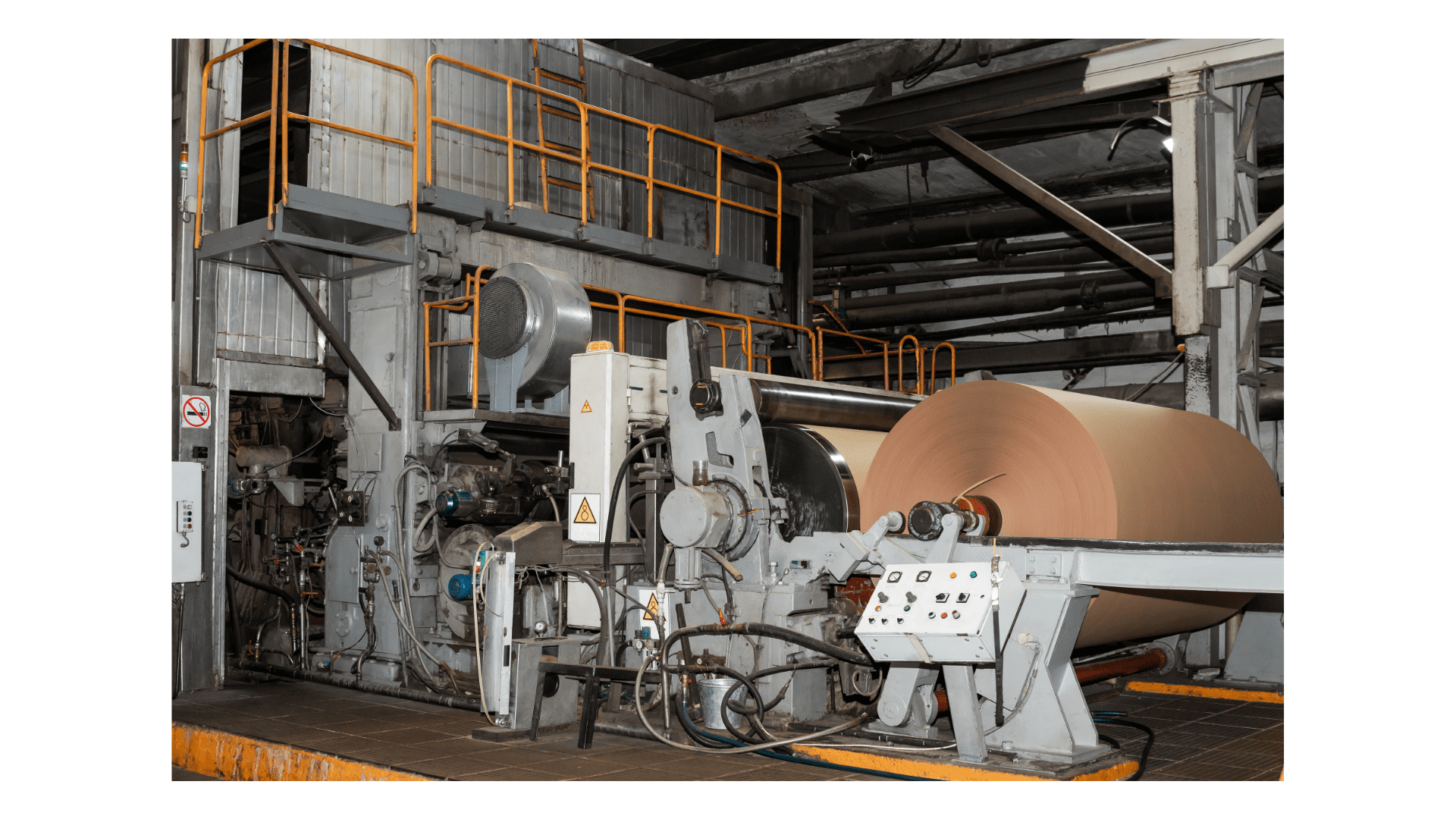

The heavy-duty motors are the first choice for all significant applications in both typical industrial settings and difficult situations because of their sturdy cast iron casing. They are incredibly adaptable, incredibly small, easy to handle, and dependable even under the worst of circumstances. Extremely high efficiency guarantee sustainable and cost-effective operation.

A customised solution for your unique needs is Innomotics SD.

The flange mounting design allows for flexibility, the tough design ensures dependability, and the efficiency class IE4 from 2.2 to 1.000 kW allows for maximum efficiency.

SD motors from Innomotics with a digital interface

The digital communication capability of the Innomotics SD motors is a clear advantage. This has numerous advantages that are beneficial to engineering during its whole life cycle.

Connect 400 / Inspire IQ Fleet

You can deploy an affordable, cloud-based solution for continuous condition monitoring and comprehensive fleet management of your low-voltage motors 24/7/365 with the plug-and-play Connect 400 connectivity module and Inspire IQ Fleet analysis app.

Your low-voltage motors’ availability, performance, dependability, and efficiency may all be improved in a variety of applications with the help of the MindSphere application Inspire IQ Fleet, whether you’re monitoring brand-new motors or adaptably upgrading the existing base. Perform maintenance on your motors in advance, basing it on accurate condition data and interval information.

Maximum efficiency at fixed speed

A new EU Directive states that low voltage motors up to 1,000 kW must reach an efficiency rating of IE3 or above as of July 1, 2021. In a second phase, efficiency class IE4 will be required for the 75-200 kW performance range starting in mid-2023.

The well-proven Innomotics SD motors are already available with the very high-efficiency class IE4 – from 2.2 kW to 1,000 kW – for mains operation up to shaft height 450.

Motors with Innomotics SD standard

The Innomotics platform’s Heavy Duty motors have long been notable for their exceptional performance and excellent dependability, even in the most demanding applications.

haft elevations 71–315

One of the world’s most compact motor ranges is the Innomotics SD line, which is produced with cutting-edge technologies. The motors’ design and the idea of modular add-ons guarantee optimal flexibility and little work during installation.

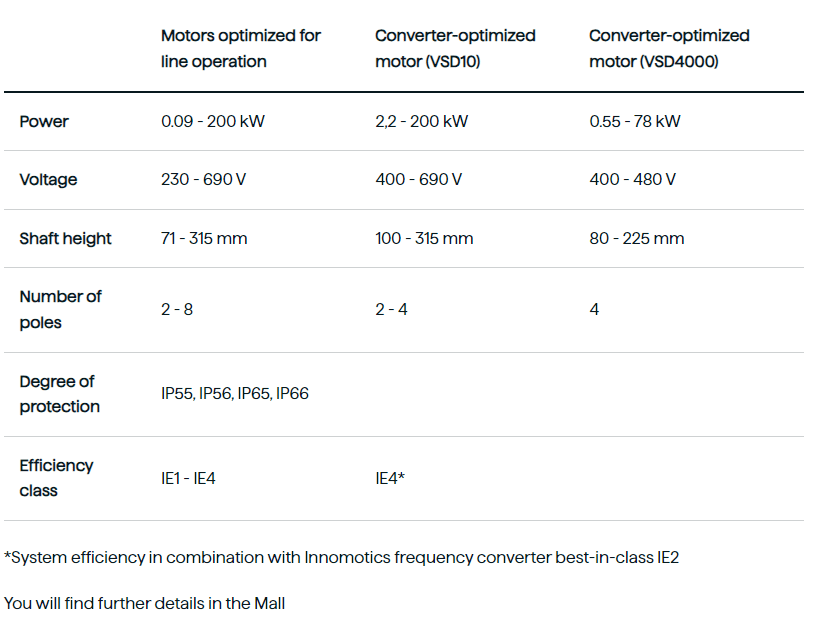

One grid-optimized standard motor and two converter-oriented motor lines for variable-speed drives with a frequency converter and motor are available for frame sizes 71 through 315.

Product overview

Motors designed with line operation in mind

Line operation is possible with the well-proven Innomotics SD motors up to motor efficiency rating IE4. When comparing motors with an IE3 efficiency class to motors with an IE4 efficiency class, you can save up to 3% on your energy consumption. Due to its revolutionary manufacturing processes, the InnomoticsSD motor series is among the world’s most compact. For example, highly conductive materials guarantee good starting and switching behaviour and low rotor losses. Installing the modular mounting idea requires little effort and offers complete flexibility.

These line motors can be used on the converter if desired, in addition to directly on the line.

Variable speed drive motors, or converter-optimized motors

Based on the Innomotics SD family, which has shaft heights ranging from 71 to 315, are the Innomotics SD VSD motors. As a result, their design matches that of the matching line motors because their mechanical components are the same. Through suitable dimensioning of the active portion and VSD-specific rating plate data, the motors are fitted to the converter. Furthermore, a great deal of the options, terminal box location, construction kinds, motor protection, and other modifications accessible for line motors are also available for VSD motors.

- Converter-optimized asynchronous motor (VSD10)

The investment-optimized system, which consists of an Innomotics SD VSD10 motor and an Innomotics converter, allows for quick commissioning using a data matrix code for preset converter parameters, as well as straightforward selection using a catalogue or engineering tool. When the motors are perfectly matched to the converter’s operating conditions, system losses are reduced, leading to high energy efficiency.

- Converter-optimized synchronous reluctance motor (VSD4000)

For particularly energy-efficient operation, the best choice is a system consisting of a Innomotics reluctance motor and a Innomotics converter. The reluctance technology ensures particularly high dynamic performance and high efficiencies even in the partial load range, as well as high process quality.

Your benefits at a glance

The effective line motor for various needs

- For severe duty applications, the following motor lines are available: Eagle Line (export to NAFTA nations), Performance Line (process industry) and Basic Line (mechanical engineering). one idea for all international markets.

- Throughout the whole performance range, a catalogue range of 2.2 kW is available for the line motors in efficiency class IE4.

The right converter motor is matched with the Innomotics converters.

When combined with converters from the Innomotics drive family, motors designed for converter operation in synchronous and asynchronous reluctance technology provide an ideally matched, extremely efficient system. They surpass the global MEPS standards. Predefined parameters in the converter are provided by the data matrix code stamped on the motor rating plate.

Energy conservation and environmentally friendly production

High energy savings and environmental protection are made possible by the IE3 and IE4 efficiency class motors. production in compliance with the strictest environmental regulations. Lacquers and impregnation don’t require solvents.

Enhanced power and a compact design

- In machines, the motor’s size frequently has a big impact. In addition to saving room, the extremely small design makes machine and plant connection easier.

- When space is limited and a normal motor cannot fit, higher power motors may be the answer—even in applications with extreme workload. This is so that they can have a lower shaft height while still providing the same power rating.

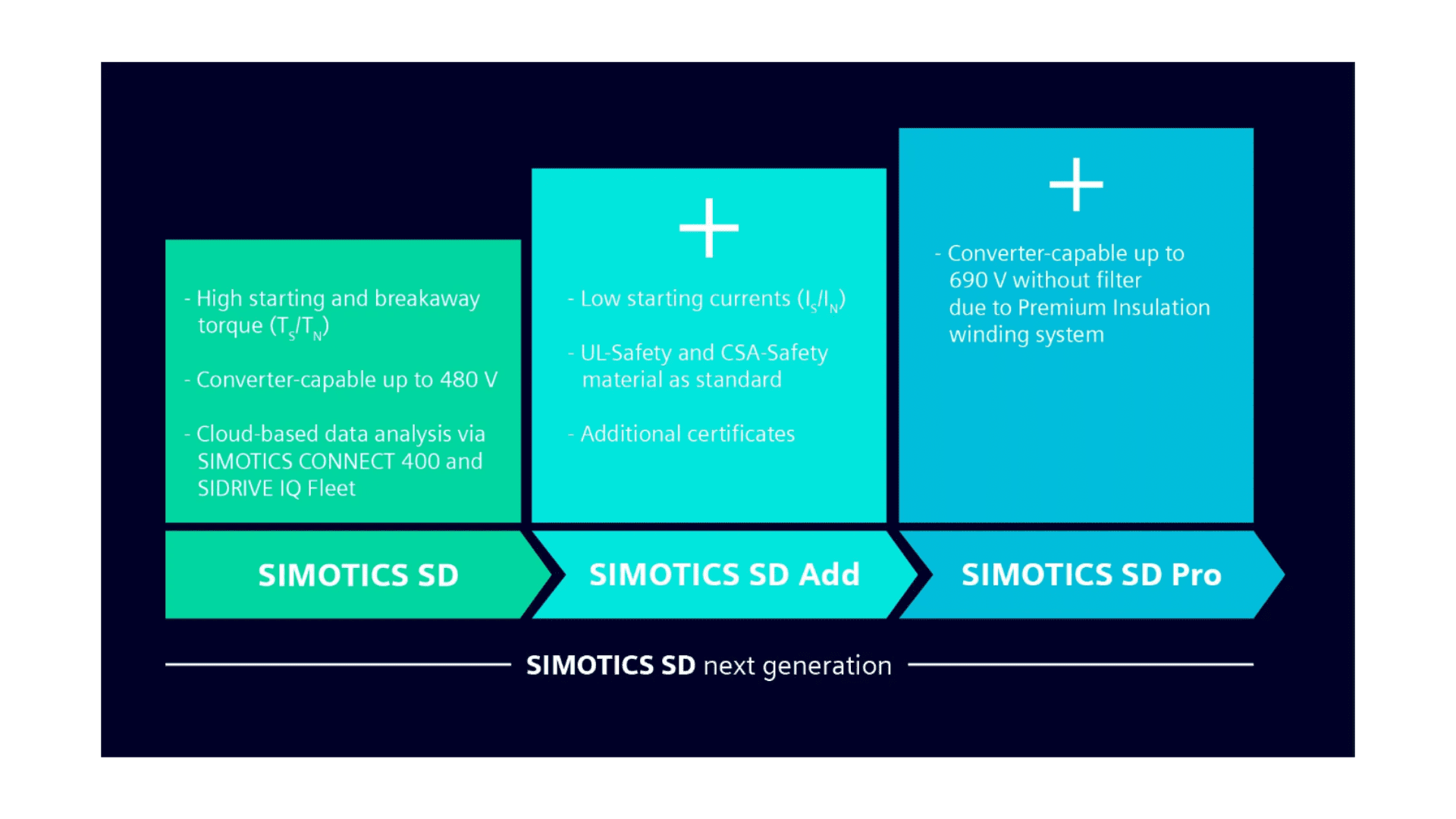

Next-generation motors from Standard Innomotics SD

A new scalable generation of low voltage motors is prepared for digitalization with the release of Innomotics SD next generation. Because of its outstanding performance and wider range of applications, this motor family guarantees drive technology that will not lag behind.

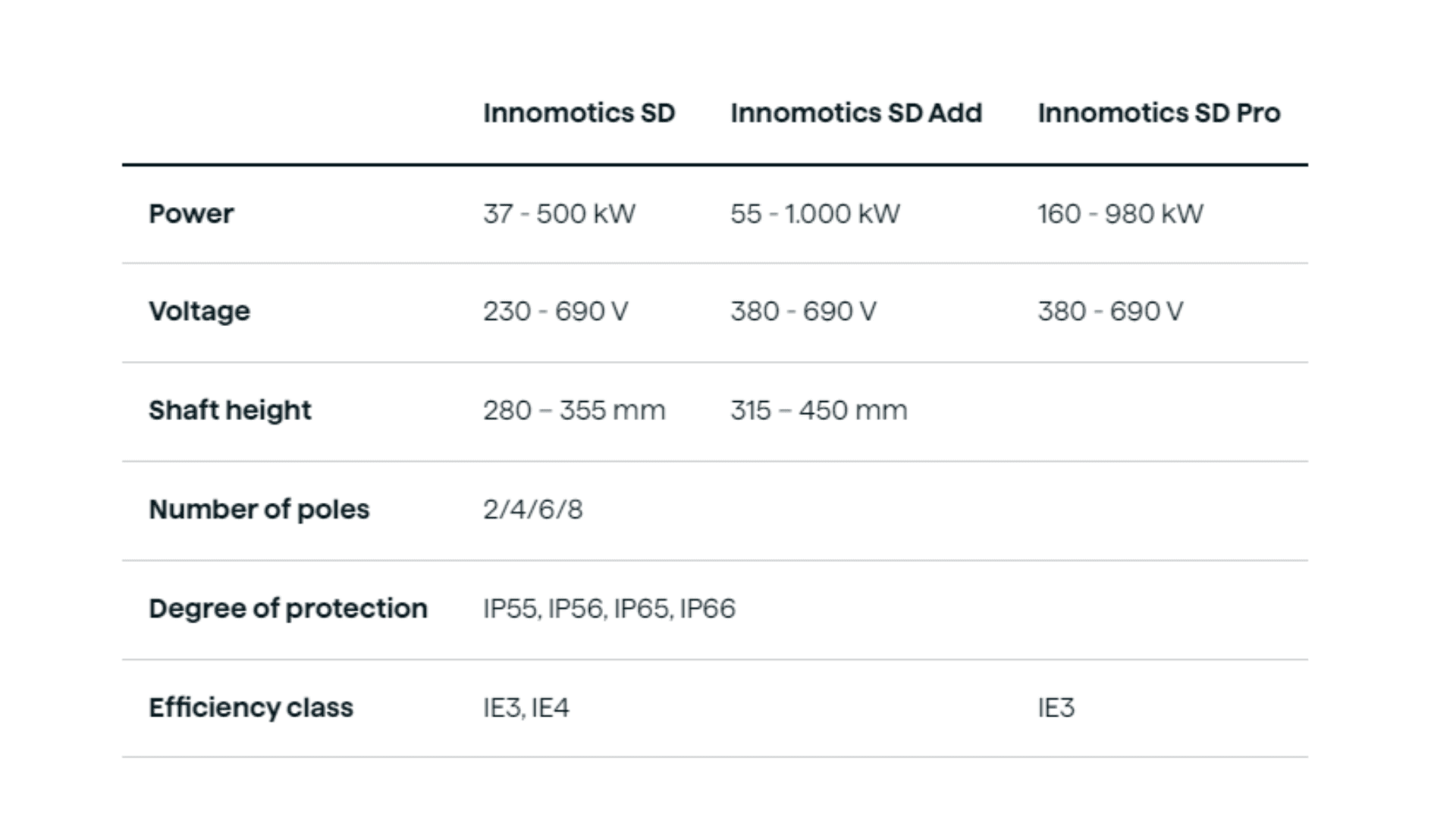

Shaft heights 280 – 450

Dust and vibrations cannot slow them down, nor can aggressive environments in the process industry. Their optimized design allows compact dimensions with a high power density. A standardized range of options and the flexible terminal box concept allow easy integration in different plant configurations and applications.

Product overview

Innomotics SD

High starting and break-loose torques are characteristics of the original Innomotics SD version. The motors are IQ Ready thanks to SIMOTICS Connect, a sensor box installed on the motor.

Innomotics SD Add

With its low starting currents and global certificates, the Innomotics SD Add version is made for applications up to 1,000 kW in all significant international markets and regions. In addition, a great deal of industry-specific needs and process industry specifications can be fulfilled due to its low beginning currents, which also improve operating quality.

Innomotics SD Pro

The third variation has exceptional scalability and versatility. In any plant or system configuration worldwide, the Innomotics SD Pro motors can be run directly from the line supply or via a converter up to 690 V. The distinctive combination of significant worldwide certificates and IE3-based efficiency stability, which is independent of the 50 Hz or 60 Hz line frequency, are two of the Innomotics SD Pro’s special features.

Innomotics SD Add and Innomotics SD Pro offer global certificates. They are therefore ready for use in all major world regions and markets. They can be used as standard in the European Union and North America. They are supplied with the electrical values stamped on the rating plate in accordance with IEC and EISA requirements. Like with the Eagle-Line for the smaller shaft heights, the motors represent a NEMA version electrically (mechanically acc. to IEC). In addition, many other country-specific certificates are available.

Benefits

Digitalization enables optimisation.

Utilise the digital pioneer to maximise service activities and increase process transparency.

- Digital twin: Streamline and increase the flexibility of engineering and design processes.

- The Innomotics Digital Data app promotes transparency and streamlines commissioning by providing mobile users with access to technical data, spare parts, and operating instructions.

- The digital platform for full drive systems, Inspire IQ Fleet offers increased serviceability, dependability, transparency, and process efficiency.

The best possible design

- improved flexibility and efficiency during installation.

- Future-proof and compact design: For a higher power density at similar performance levels.

- Smaller overall dimensions: To save space and make replacement easier.

- A new idea for a terminal box that will allow for more flexibility when integrating systems.

- Better operational quality: For low starting currents (IS/IN) or high beginning or break-loose torques (TS/TN).

- Applications that are flexible: up to 690 V for mains and converters.

Concepts for energy efficiency that are focused on the future increased competitiveness as a result of energy conservation.

- Adherence to efficiency classifications IE3 and IE4: Optimise energy conservation and considerably lower overall cost of ownership.

- IEC 61800-9-2 compliance with IES2 for Innomotics drive systems:

Find out how minimal Innomotics SD motor system losses are when used with SINAMICS converters. - Efficiency stability: Gain from continuously high efficiency at any line frequency between 50 and 60 Hz.

Simple and fast processes

Acquire the next level of performance throughout the whole value-added chain.

- Extremely quick delivery: Increase your planning flexibility and time.

- Additional setup choices:

Use a larger selection of standardised alternatives to receive quotations more quickly and receive responses more quickly. - Global reach: Adherence to local regulations and the main international certifications.

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.