SIMOTICS M-1PH8 main motors

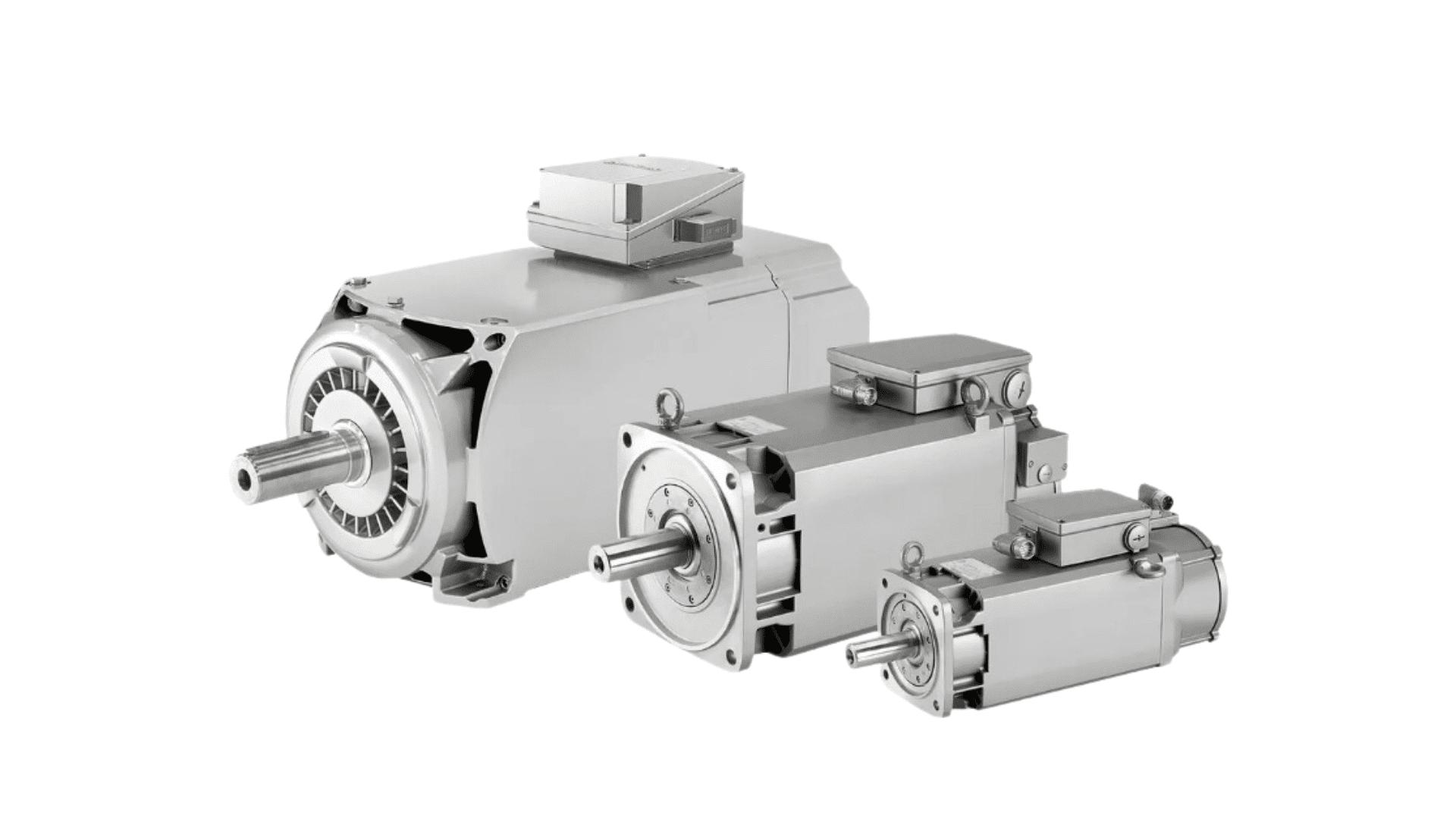

The SIMOTICS M-1PH8 motor is specifically engineered to function as the primary drive in manufacturing machinery and machine tools. The motors are offered with synchronous-reluctance technology in addition to asynchronous and synchronous variants. For almost all drive applications, there is a SIMOTICS M-1PH8 motor that is appropriate, based on an adaptable modular kit architecture.

Set up now

Overview of the product range

The intricate modular design provides many cooling and protection levels, along with multiple ways to incorporate the primary motor physically and electrically.

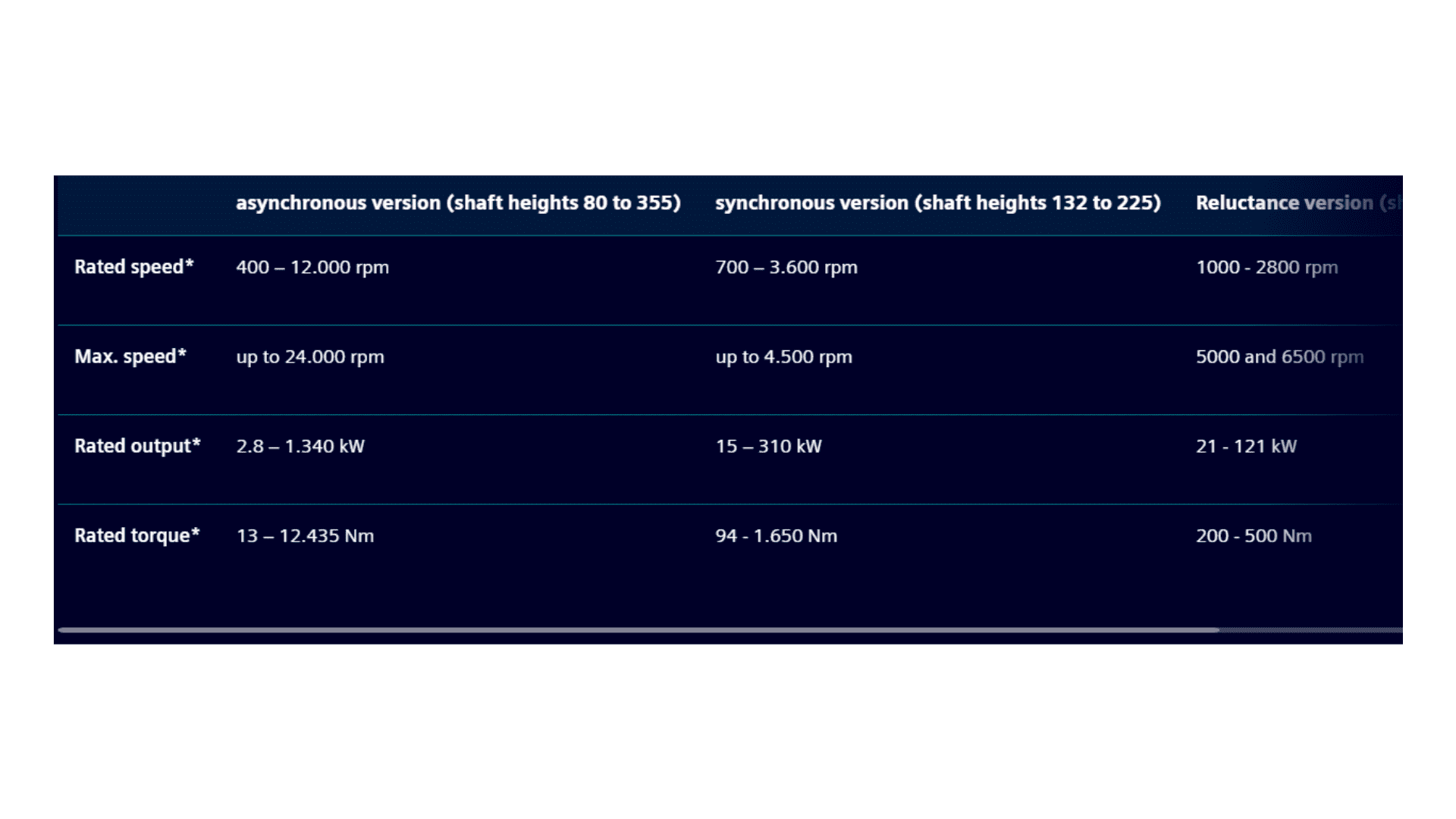

SIMOTICS M-1PH8 – Asynchronous version

For applications where accurate, smooth running characteristics and precise controllability of the axes are the primary focus, in addition to higher drive power. Additionally, they can be used in conjunction with SINAMICS G120 converters, whose broader speed range, as compared to normal main motors, expands the applications that they can realise. They may now tackle novel, more compact machine concepts as a result.

SIMOTICS M-1PH8 – Synchronous version

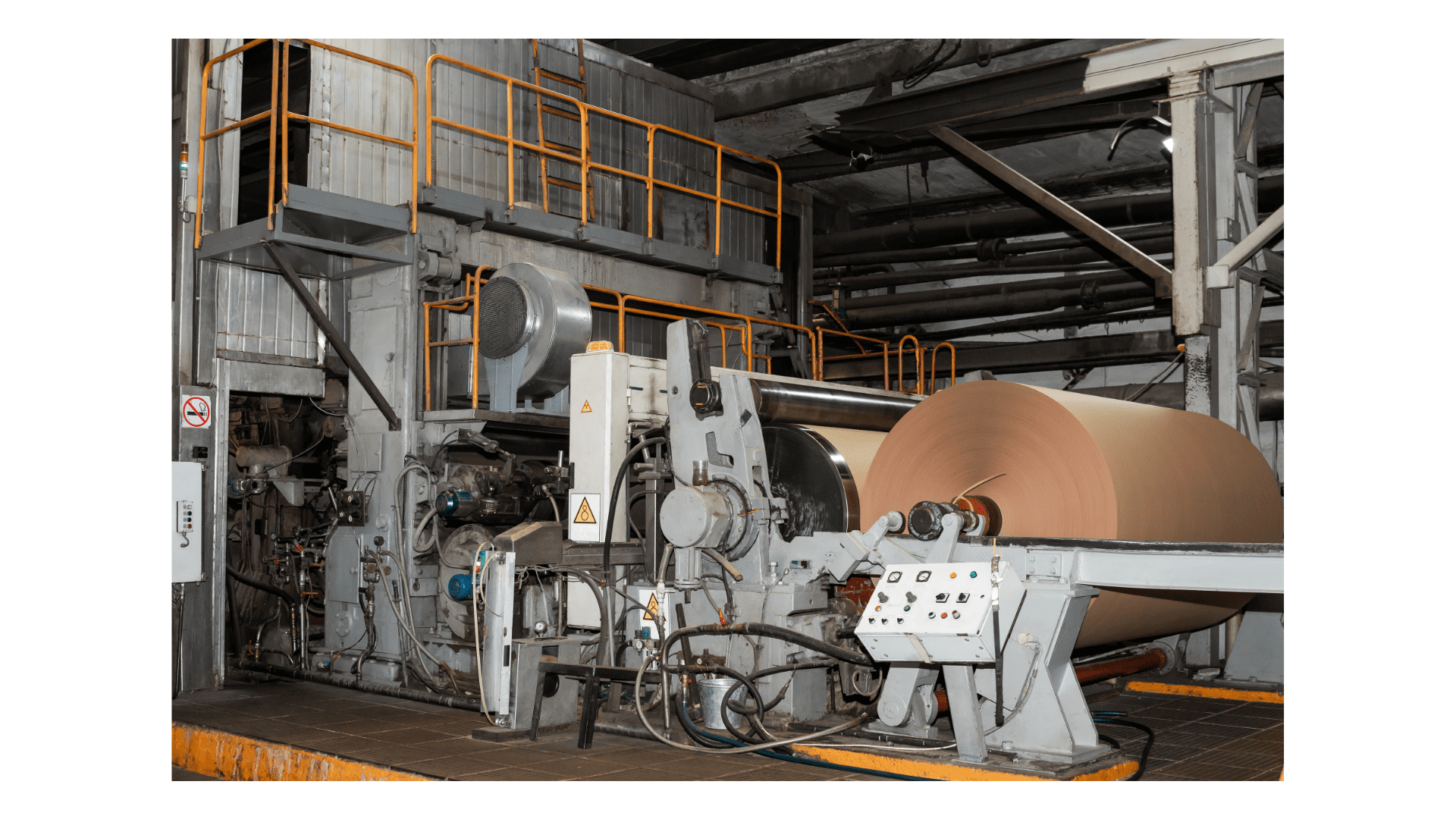

Our tiny SIMOTICS M-1PH8 synchronous motors offer unparalleled smooth running performance when high rated torques are the main focus. Offering a multitude of choices, they may be easily tailored to any need and come with water cooling or forced ventilation. This is a common requirement not only for printing machines and machine tools, but also for rod mills, servo presses, and other equipment.

SIMOTICS M-1PH8 – Reluctance version

Reluctance motors made by SIMOTICS M-1PH8 are a good option for applications requiring a high energy throughput and a reduction in life cycle costs.

The motors with reluctance exhibit remarkably elevated power density and efficiency. Both an improved “Efficiency” and an improved “Performance” version are offered.

Offering a multitude of choices, they may be easily tailored to any need and come with water cooling or forced ventilation. Applications such as extruders in blow moulding machines, winders, wire drawing machines, compressors, or servo pumps are typical examples of main drive operations with brief idle times.

Technical overview

The dynamic powerhouses for mechanical and plant engineering

Quick and simple commissioning and trouble-free operation are guaranteed by the carefully harmonised power components, electronic rating plates, and the possibility to integrate the motors via the DRIVE-CLiQ system interface. Additionally, they can handle high duty cycles, quick rising times, and remarkable precision in terms of torque, speed, and placement because of the system’s harmonisation.

M-1PH8 Main Motors are squirrel cage motors covering a particularly broad performance spectrum.

Benefits:

- Extended power range from 2.8 kW to 1340 kW

- Flexible configuration options

- High smooth running characteristics and ruggedness thanks to the outstanding true running and low vibration severity at maximum speeds of up to 24,000 rpm

- High dynamic performance and short accelerating times

- Simple and flexible connection system

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.