SIMOTICS M-1FE built-in motors

Our SIMOTICS main motors are tailored to the increasing demands of modern plant and mechanical engineering. Available in robust asynchronous or synchronous designs, they are characterized by short rise times and tackle even the most extreme load cycles with a high accuracy in speed, torque and positioning.

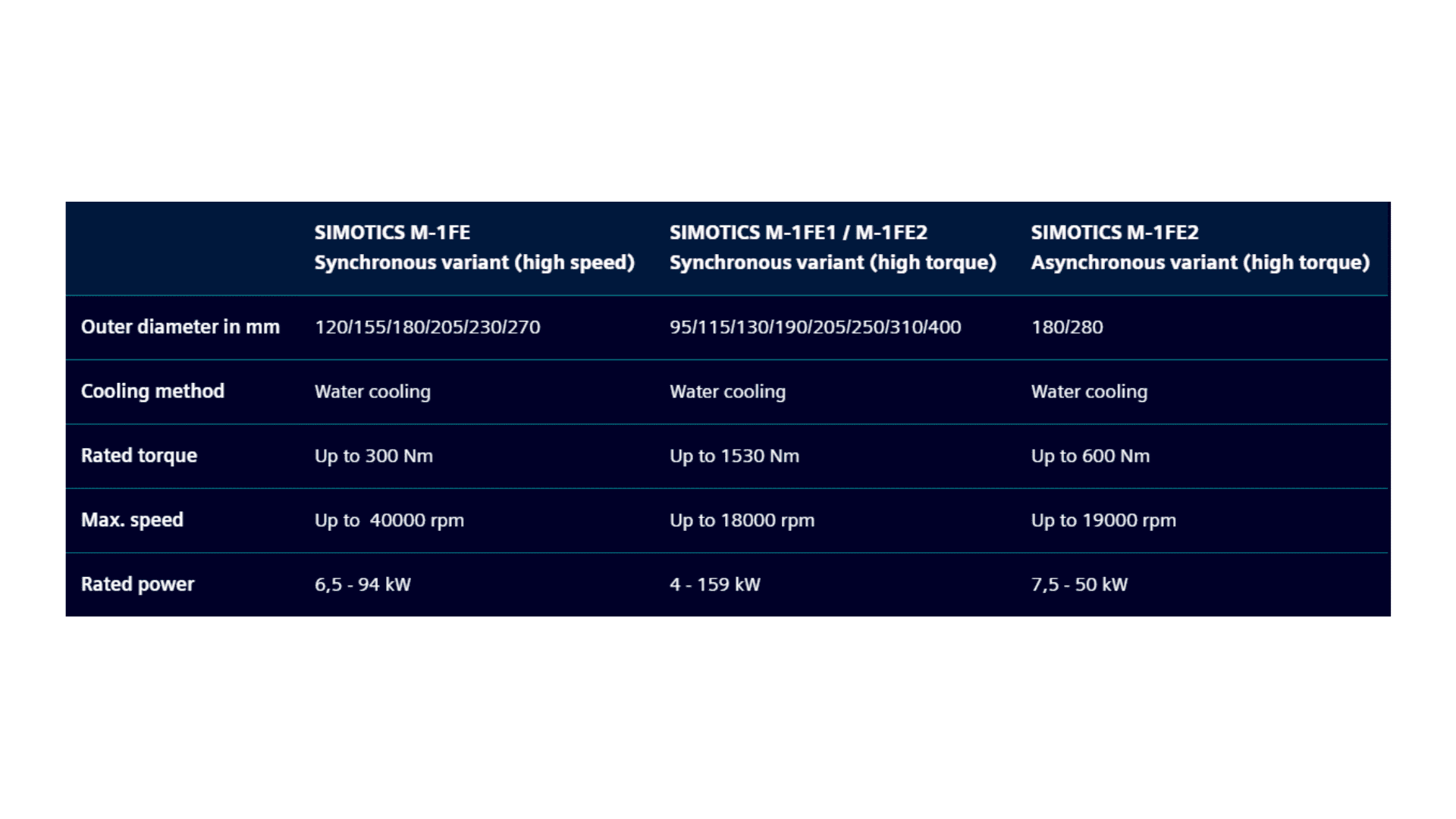

Overview of the product range

There are synchronous and asynchronous SIMOTICS M-1FE built-in motor versions available with water cooling. You can choose between the high torque and high-speed variations based on the required speed or torque.

SIMOTICS M-1FE2 is the new generation of built-in motors in asynchronous technology

- For directly driven motor spindles in turning, milling, grinding, and multitasking machines, SIMOTICS M-1FE2 asynchronous built-in motors are utilized.

- They have a far better torque density, faster maximum speeds, a larger constant power range, and a higher overload than the previous series.

- This implies that applications for machines in job shops and mold manufacturing, as well as turning, milling, and grinding machines, can be addressed more thoroughly in addition to the SIMOTICS integrated synchronous motors.

SIMOTICS M-1FE1 synchronous built-in motors for the highest speeds and torques

The SIMOTICS M-1FE1 synchronous built-in motors are designed specifically for use in machine tools and are characterised by their compact size and outstanding dynamic performance. Their exceptional machining quality, quick ramp-up periods, maximum precision, and smooth operation define them. Versions for very high torque utilisation or high maximum speeds (high speed) are available, depending on the application. There are no mechanical gearbox components involved in the direct transfer of mechanical motor power to the spindle. Both the rotor and stator feature water cooling and are machined and ready for installation.

Technical overview

Benefits at a glance

- Compact design obtained by dispensing with mechanical components

- Short acceleration and braking times

- High degree of rigidity thanks to large internal rotor bores (and a therefore large shaft diameter)

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.