Servo geared motors

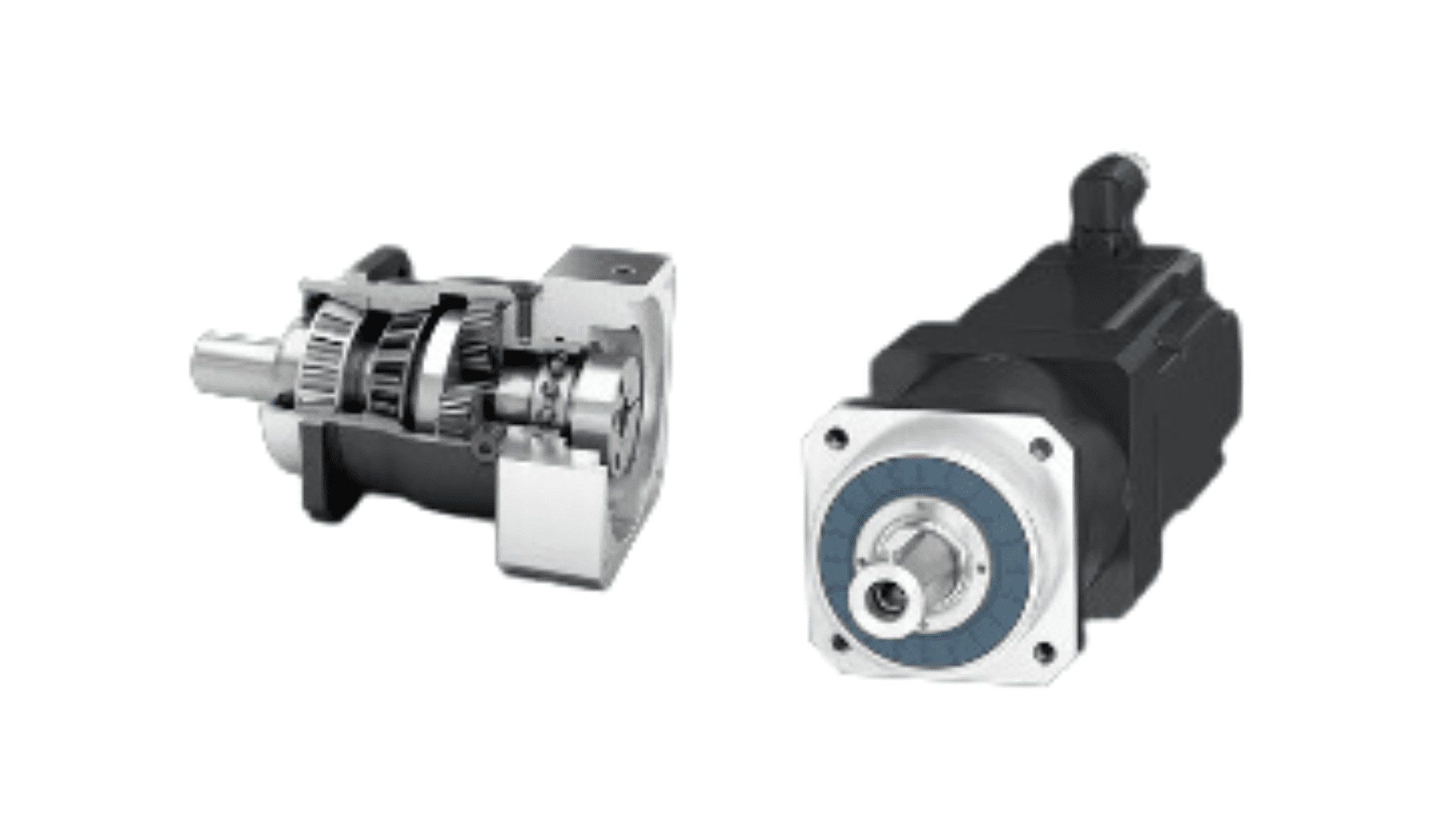

Gear-driven motors are suitable for a variety of uses. We provide a large variety of geared motor variations because geared motors are incredibly adaptable. Numerous applications can be served by servomotors outfitted with affordable planetary gearboxes and great precision.

In motion control applications, you gain from compactness and smooth operation. Using a KS adapter, gearboxes can be mounted to our servomotors and main motors in addition to a premounted option. Our motors that come with standard gearboxes perfectly complete the line-up.

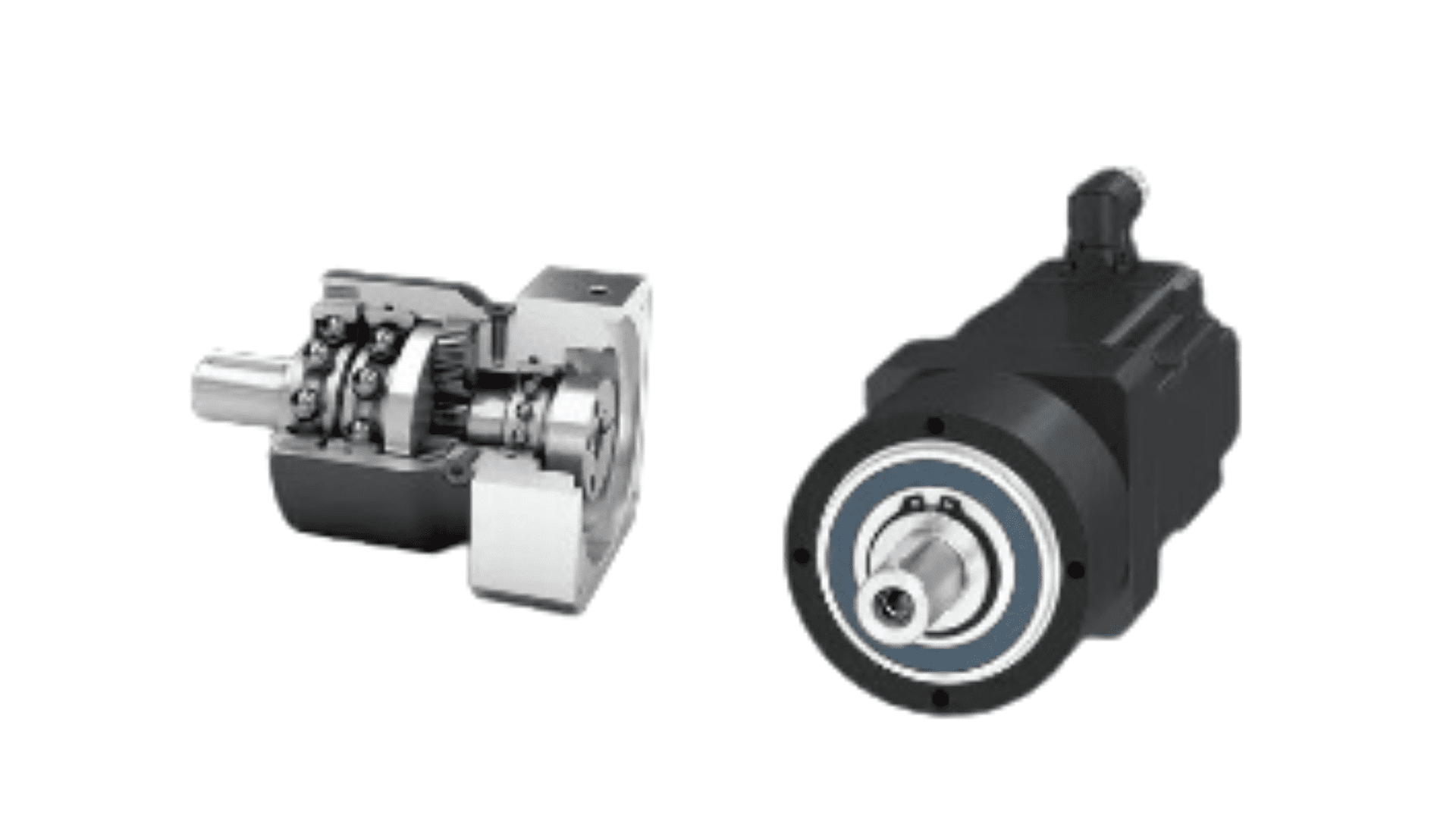

Servo planetary geared motors SIMOTICS S-1FK2: the pre-mounted gearbox solution

The maximum number of cycles is made possible by SIMOTICS S-1FK2 servo planetary geared motors, which also provide light gearbox variants with low moments of inertia or ones whose moments of inertia have been modified to precisely move large loads.

The large range of gearbox sizes and ratios allows the gearbox to be precisely matched to the application. The digital twin of the geared motors in the TIA selection tool makes the thermal dimensioning as easy as it is for a servomotor.

Benefits

- Optimum adaptation of the torque-speed ratio and/or the mass moment of inertia ratio between the motor and load

- Premounted, tested and ready to run servo geared motor solutions based on 3 gearbox variants

Product selection

SIMOTICS S-1FK2 with NLC gearbox

The NLC gearbox has a high degree of rigidity and is ideal for strong radial and axial loads because of the preloaded tapered roller bearing. Water and dust are protected by the IP65 sealing system.

- Rated output torques: 1.51 … 240 Nm

- Gearbox transmission ratios: 3 … 100

- Gearbox stages: 1 and 2-stage

- Torsional backlash: 7 … 10 arcmin

- Degree of protection: IP 65

- Type of construction: IM B5

SIMOTICS S-1FK2 with NRK gearbox

NRK gearboxes are appropriate for larger radial and axial forces because of their big output bearing. Because these gearboxes have no internal friction, they can also operate at higher speeds.

- Rated output torques: 2.25 … 450 Nm

- Gearbox transmission ratios: 3 … 100

- Gearbox stages: 1 and 2-stage

- Torsional backlash: 8 … 20 arcmin

- Degree of protection: IP64

- Type of construction: IM B14

SIMOTICS S-1FK2 with NRB gearbox

With the maximum power density, the NRB is the lightest gearbox available. Its low friction bearing design allows it to run at high speeds with minimal temperature rise.

- Rated output torques: 2.2 … 650 Nm

- Gearbox transmission ratios: 3 … 320

- Gearbox stages: 11, 2 and 3-stage

- Torsional backlash: 6 … 22 arcmin

- Degree of protection: IP64

- Type of construction: IM B14

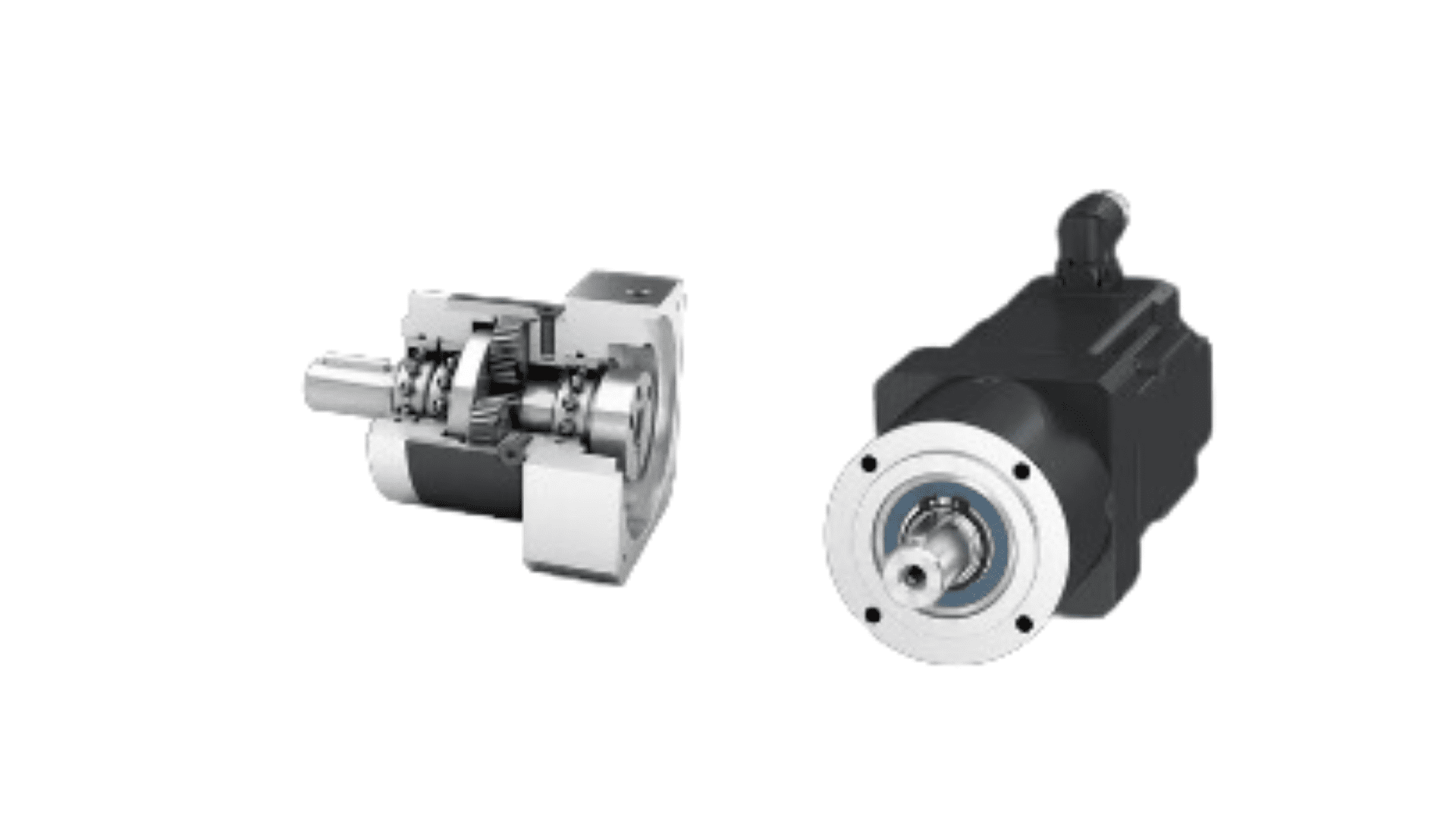

SIMOTICS S-1FK7, S-1FT7 planetary geared motors

Servomotors with planetary gearboxes are the optimum choice for motion control applications with high to very high accuracy and dynamic response requirements.

Three different versions are available, depending on the requirements:

SIMOTICS S-1FK7 / S-1FT7 servomotors with SP+ planetary gearboxes

- Torsional backlash: ≤ 4 or ≤ 6 arcmin (one or 2-stage)

- Efficiency: > 94 or > 97 % (one or 2-stage)

- Gearbox transmission ratios: 4 to 50

- Mounting type: Coaxial with a coupling

- Degree of protection: IP 65

- Mechanical design: Solid shaft design with and without feather key

SIMOTICS S-1FK7 servomotors with NP planetary gearbox

- Torsional backlash: ≤ 12 arcmin

- Efficiency: > 97 %

- Gearbox transmission ratios: 5 and 10

- Mounting type: Coaxial with a coupling

- Degree of protection: IP64

- Mechanical design: Solid shaft with feather key

SIMOTICS S-1FK7 DYA directly mounted planetary gearbox

- Torsional backlash: ≤ 8 arcmin

- Efficiency: > 97 %

- Gearbox transmission ratios: 5 and 10

- Mounting type: Coaxial, directly mounted

- Degree of protection: IP64

- Mechanical design: Especially compact, solid shaft with feather key

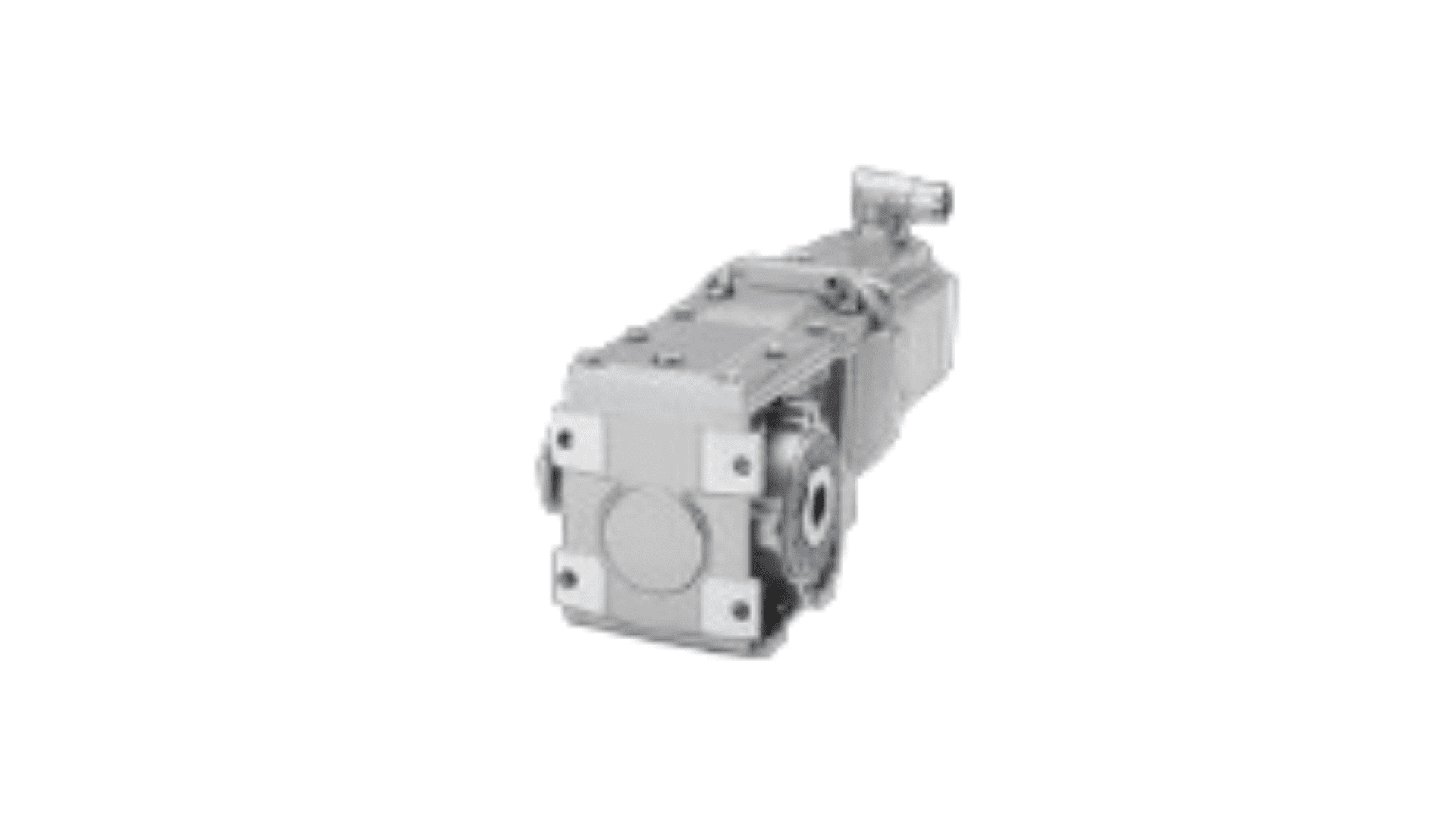

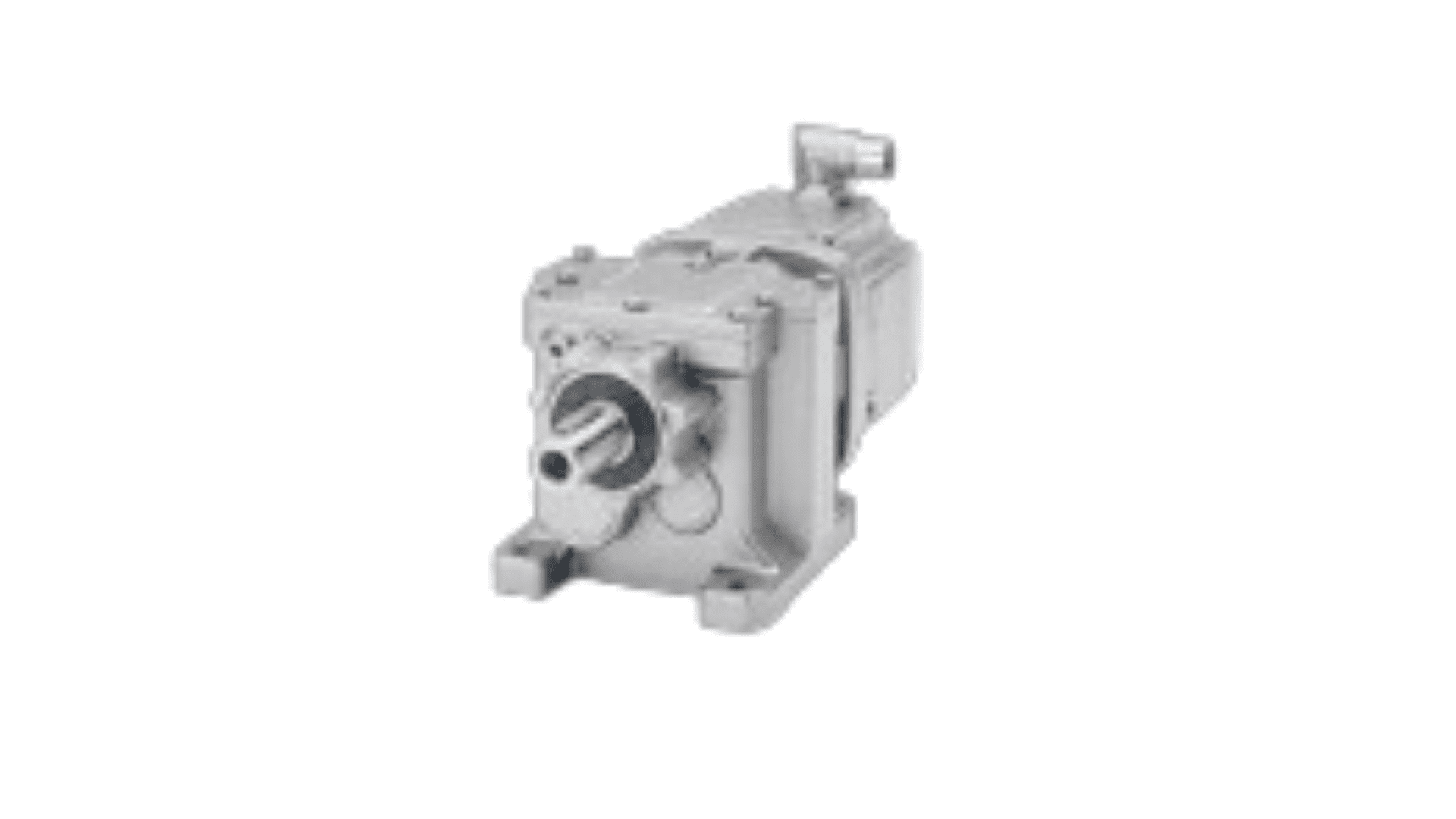

SIMOTICS S-1FG1 servo geared motors – open to accept a wide range of gearboxes

SIMOTICS S-1FG1 servo geared motors are compact geared motors. When compared to standard geared motors with induction motors, they set themselves apart as a result of their more compact dimensions, lower weight and higher dynamic performance. The range of types encompasses helical, parallel shaft, bevel and helical worm geared motors in the usual sizes and speed/torque graduations. SIMOTICS S-1FG1 servo geared motors use the same gearbox heads as for SIMOGEAR geared motors.

Benefits

- Extremely compact design as a result of the direct mounting (because there is no coupling cage between the motor and gearbox)

- Maintenance-free and lubricated for life

- High efficiency and low torsional backlash

- Low running noise due to the helical teeth

Servo bevel geared motor

- Transmission ratio range: 3.5 to 244.3

- Torque range: 15 to 8160 Nm

- Efficiency, two/three-stage: 96 / 94 %

- Torque transmission rotated through 90°

- Solid shaft or hollow shaft with different shaft fastenings

- Flange and foot-mounted, tapped group of holes, torque arm

Servo parallel shaft geared motor

- Transmission ratio range: 3.6 to 413

- Torque range: 17 to 5140 Nm

- Efficiency, two/three-stage: 96 / 94 %

- Parallel torque transmission

- Solid shaft or hollow shaft with different shaft fastenings

- Flange and foot-mounted, tapped group of holes, torque arm

Servo helical geared motor

- Transmission ratio range: 3.4 to 373

- Torque range: 14 to 5200 Nm

- Efficiency, two/three-stage: 96 / 94 %

- Axial torque transmission

- Shaft with feather key

- Foot and flange-mounted desig

Servo worm geared motor

- Transmission ratio range: 6.2 to 102.5

- Torque range: 46 to 1480 Nm

- Transmission ratio-dependent efficiencies from 60 up to 90 %

- Torque transmission rotated through 90°

- Solid shaft or hollow shaft with different shaft fastenings

- Flange and foot-mounted, tapped group of holes, torque arm

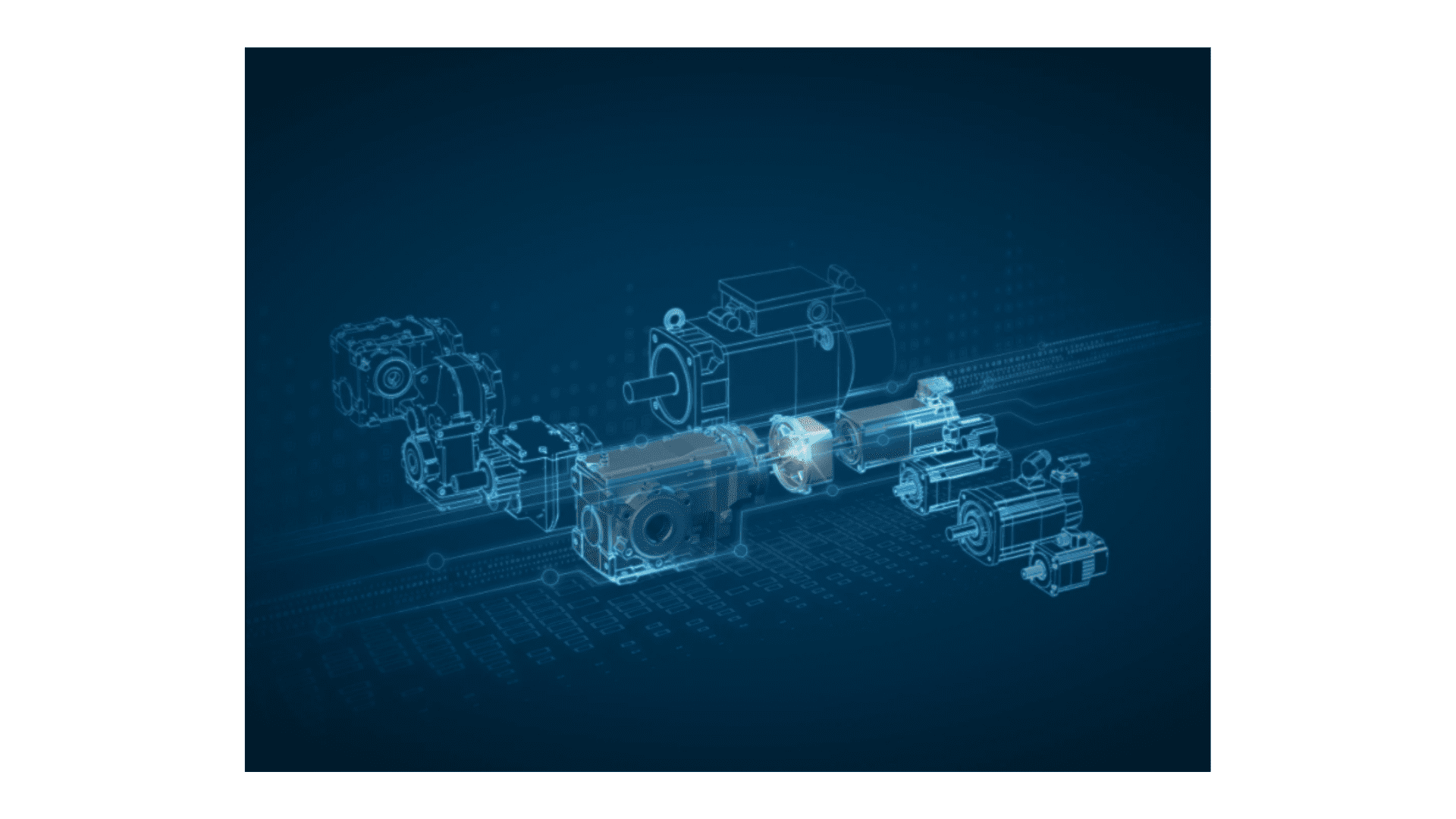

SIMOGEAR KS coupling adapters

SIMOGEAR KS coupling adapters provide an additional flexible solution to connect SIMOTICS motion control motors to various SIMOGEAR gearbox units.

This method greatly simplifies handling by allowing several kinds of gearboxes to be attached to SIMOTICS servomotors or main motors. Some benefits of this adapter solution include reduced costs and downtime due to easy installation and removal, optimised stock inventory, and lack of torsional backlash.

This idea allows connections to be made as usual for highly precise applications without the need for a feather key. Applications with strict criteria for precision, position, dynamic performance, compactness, and weight are particularly well-suited for this solution.

Benefits

The SIMOGEAR gearbox portfolio from Siemens can be simply connected using the KS adapter. Four different gearbox types are available:

- Helical gearboxes

- Parallel shaft gearboxes

- Bevel gearboxes

- Helical worm gearboxes

Optimum adaption of the torque-speed ratio and/or the mass moment of inertia ratio between the motor and load.

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.