EXPECT MORE.

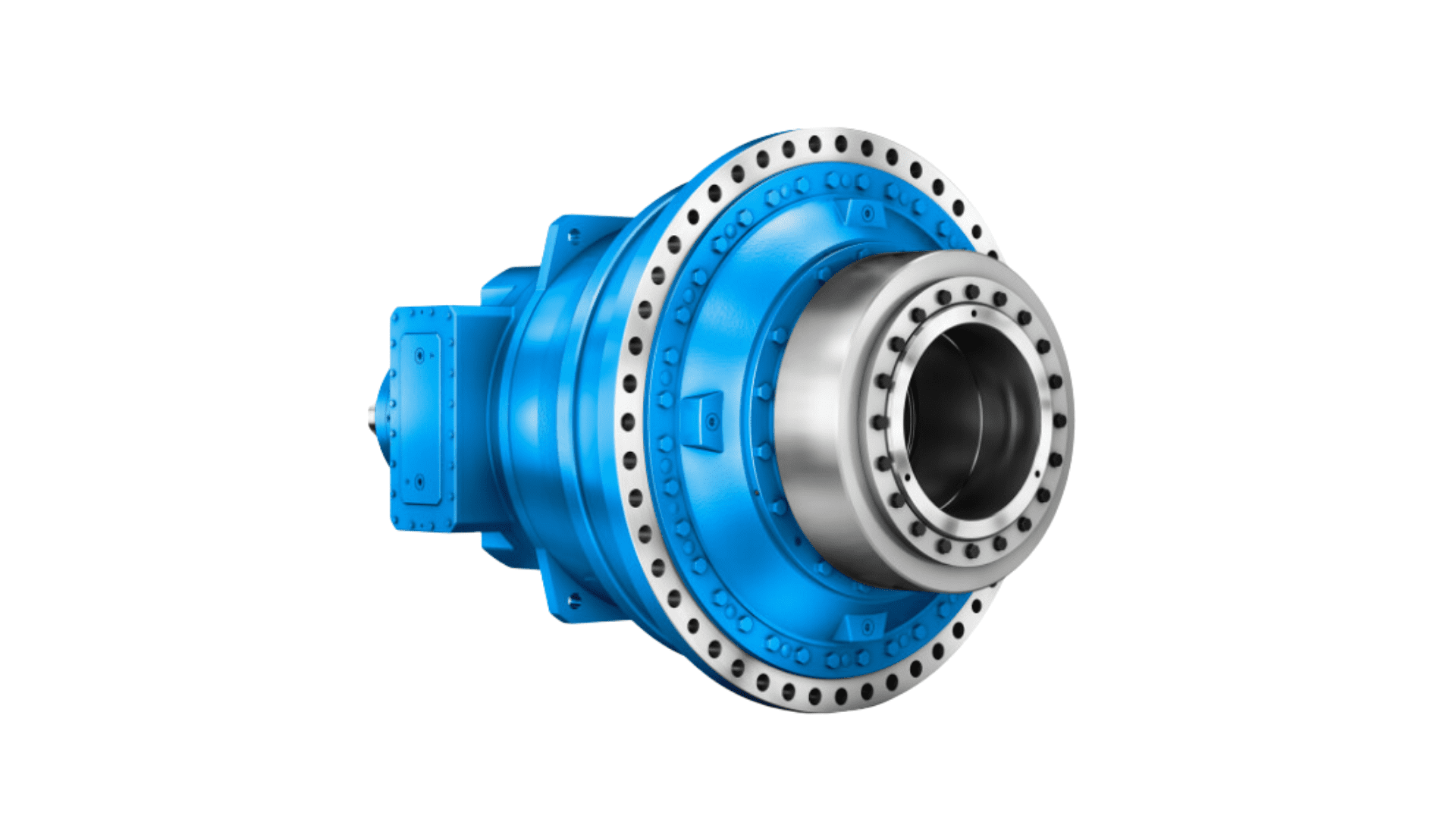

PLANUREX 3

AIM HIGHER.

- Planetary gear unit for horizontal and vertical mounting positions

- Rated torque from 480,000 Nm up to 5,450,000 Nm (17 sizes)

- Transmission ratios from i = 1:45 up to 1:300

The world of driving has many elements to premium. These are the outcomes of what consumers expect from a product and how those expectations are met. These standards are redefined with our PLANUREX 3 gearboxes. PLANUREX 3 is the brand name for a new generation of premium planetary gearheads that are incredibly power-tight and multifunctional.

A comprehensive range of fully standardized planetary gear units, rapid global delivery, an outstanding price/performance ratio, and a high degree of adaptability are all provided by PLANUREX 3. The idea achieves the best possible balance between availability, prices, and power density.

Our gear units need to be able to handle the highest loads along with massive axial and radial forces because plants are frequently run at or beyond their design limitations. As a result, we provide incredibly small premium drive solutions with PLANUREX 3, which guarantees optimum operational reliability even with sporadic loads and satisfies the strict criteria of continuous operation. This new gear generation significantly increases the availability of your work machine and provides the maximum power density together with incredibly durable gear units.

The series offers you various options for optimally adapting the gear unit to the requirements of your application, e.g:

- Gear unit base for base mounting

- Torque shaft support

- Support 2 (Chun version)

- Connection for oil cooling

- Suitable for temperatures down to -40 °C

Your benefits at a glance

- Highest power density: compact, lightweight, powerful

- High efficiencies and maximum efficiency

- Highest quality and reliability

- High overload capacity: Nominal torque x 2

- Very high modularity

- Many sizes in harmonic gradation close to the desired torque

- 3D design with FEM

- Available i. e. individually or as integrated drive train

Applications

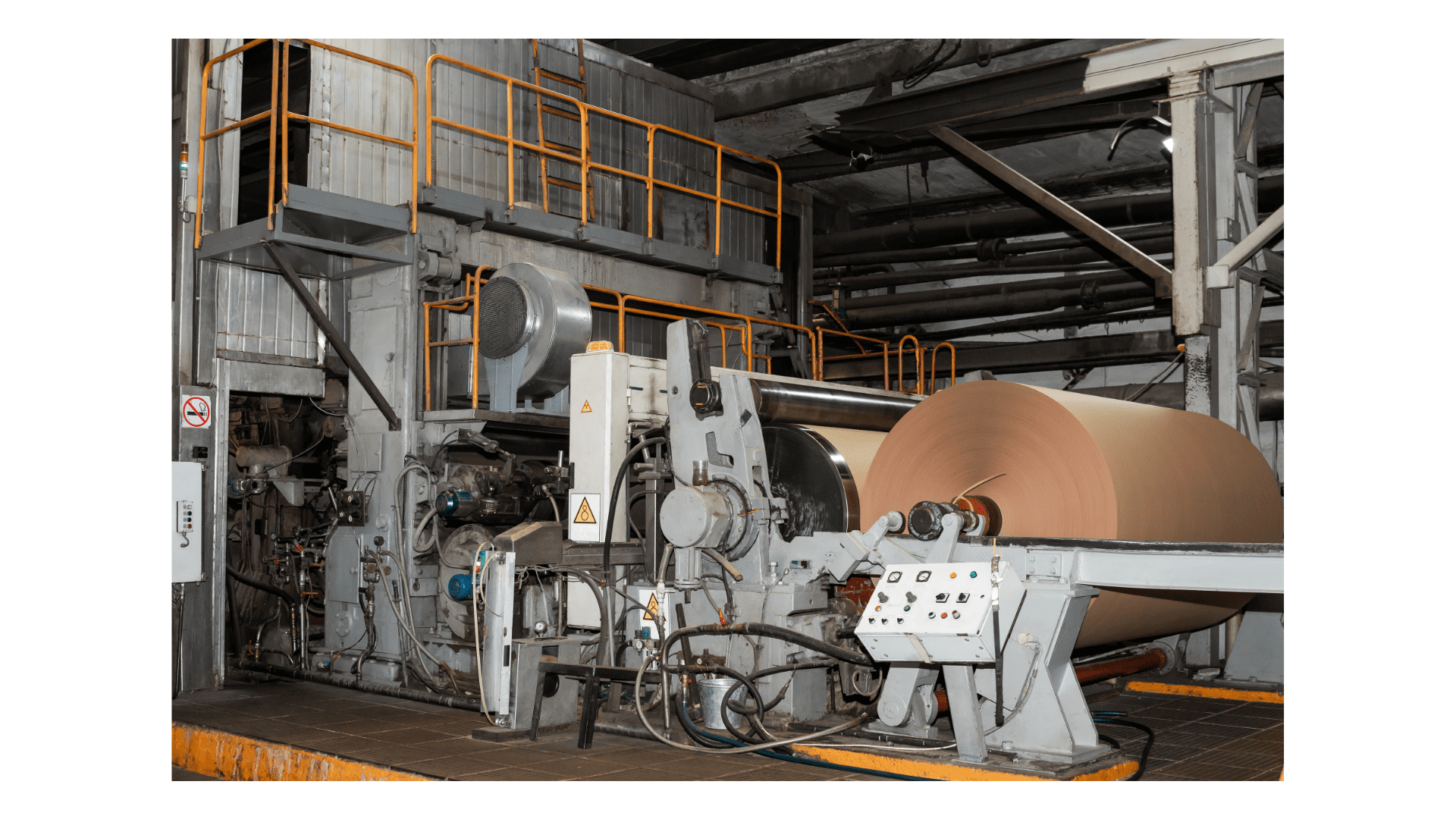

- Roller presses

- Sugar cane mills

- Central drive

- Apron feeder

- Vertical mill drives

- Travel drives

- and many more

Were you aware of this already?

The next development in drive technology is called DIAGNOSTEX. We provide the option to add measurement sensors to our gearboxes so that they can be used to continuously check the systems’ performance. This allows for the planning and anticipation of any maintenance needs, the reduction of maintenance expenses, and the avoidance of downtime.

Powering Your Industry With Precision: Introducing FLENDER SIP – Simplifying Efficiency, Elevating Performance.

PLAYMAKER IN THE PREMIUM LEAGUE

- Planetary gear unit with high power density which can be installed horizontally or vertically

- Nominal torque range from TKN = 10,000 Nm to 80,000 Nm with 8 sizes

- Nominal transition range from i = 25 to 15,000

We provide you with a range of dependable, fatigue-resistant, and precisely spaced gear unit options with FLENDER SIP® planetary gear units. The series guarantees that quality and performance have a reasonable relationship to life cycle costs and pricing, and it contains the highly integrated planetary gear motor in addition to maximum compliance with all international motor standards.

There are eight frame sizes, six gearbox ratios and five output shaft types available in the FLENDER SIP series of gear units. A variety of alternatives are available to guarantee that the gear units can be placed in any application, including flanged shafts, hollow shafts with shrink discs or splines, and cylindrical shafts with parallel keys or splines. Up to 53 steps are available in a very precisely spaced spectrum of gearbox ratios with coaxial and 90° FLENDER SIP gear units. The accessory program offers all the connecting adapters required for standard motors, including servomotor and IEC/NEMA motor connections.

Additionally, a design for temperatures as low as -40 °C, taconite seals, temperature control, explosion protection, and a variety of mounting choices ensure maximum availability and fail-safe operation even in challenging environmental circumstances.

Reliability and flexibility are now products thanks to FLENDER SIP. Take advantage of the unique FLENDER SIP attributes in the premier league to achieve the desired efficiency.

Your quick advantages

Maximum power output and optimal dependability

Best performance and high efficiencies

Transmission ratios that are finely spaced and have up to 53 steps

The motor’s compliance with all international motor and interface standards allows for maximum freedom in the selection process.

For a simple connection to the work machine, there are five output shaft types.

either as an integrated drive system or as a single gear unit

Made in Germany, worldwide in use

- Mining and Cement: apron conveyors, bunker dischargers, scratchers

- Steel Production: pilger rolling mills and reversing rolling mills

- Food and Beverage: mixers

- Other fields of application: chain conveyors

Did you know?

The combination of the FLENDER SIP with the SIMOGEAR geared motors results in an incredibly wide selection of product variants. This means that almost any drive task can be solved ideally.

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.