Only the best for our Motion Control motors

For your motion control applications, choose our specially designed products such as Motion-Connect connection technology and measuring systems. This facilitates the project planning and commissioning of system solutions for a wide range of tasks in plant and machine engineering

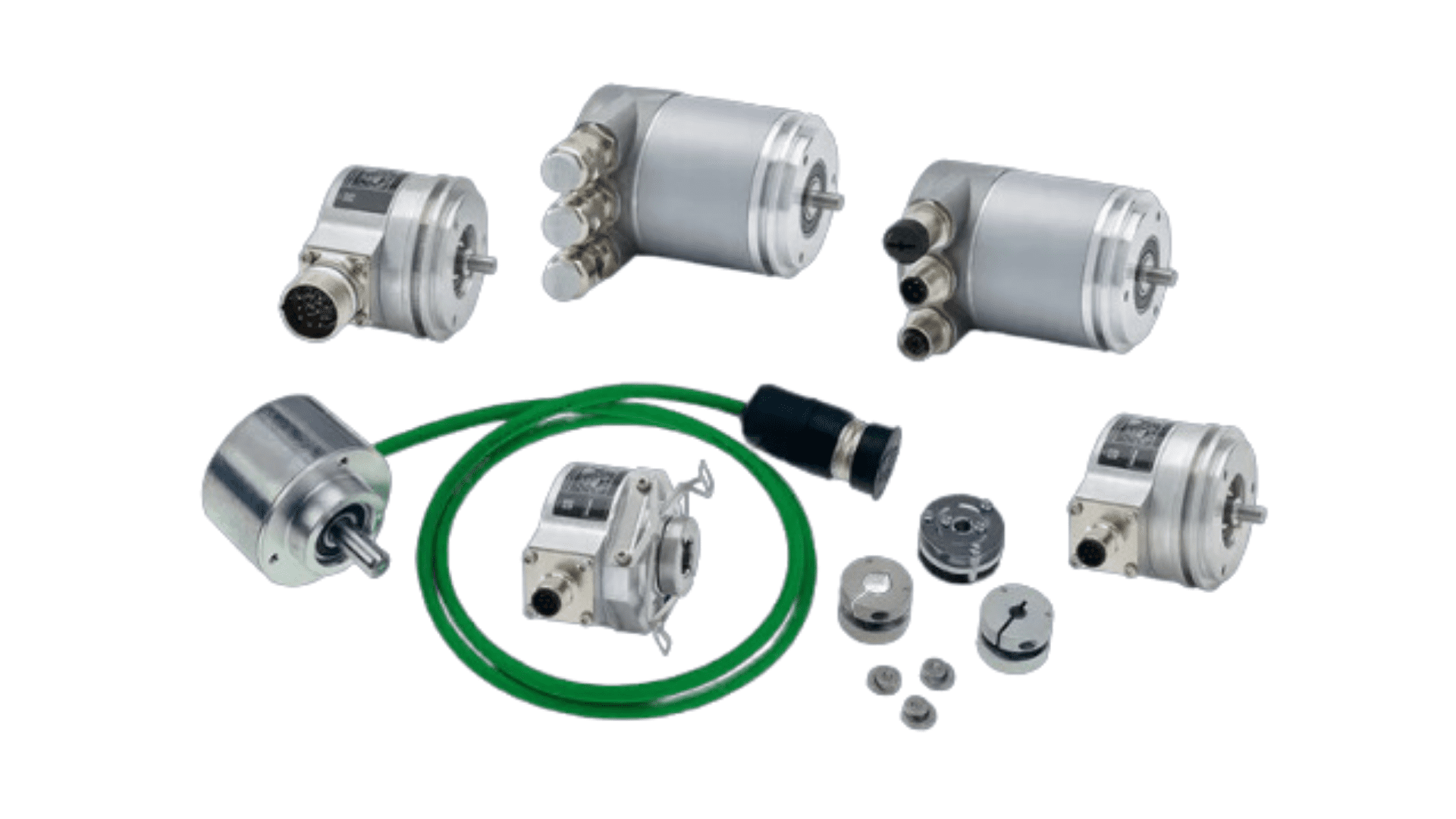

Motion Control encoder measuring systems

For the best location sensing

Optoelectronic encoders used for motion control are used to measure traversing distances, rotational angles, machine axis positions, and speeds. Direct measurement devices called motion control encoders are fixed to shafts, axes, or motors. They can be employed with drives, position displays, and numerical and programmed logic control systems.

Design

- All motion control encoders are available as synchro flange and clamp flange versions. The absolute encoders are also available with a hollow shaft and torque arm.

- The motion control encoders are driven via a plug-in coupling or spring disk coupling. Alternatively, belt pulleys can also be used.

Benefits

- Vibration resistance

- Replaceability in the field

- Without removing the motor (from the machine)

Incremental encoders

Incremental encoders detect relative movement and deliver a defined number of electrical pulses per revolution as well as a reference mark, which represents the measurement of the distance or angle travelled through.

Absolute encoders

An absolute angular location between 0 ° and 360 ° is output by absolute encoders. Despite having more tracks than incremental encoders, they function according to the same scanning concept. For instance, in the case of single-turn encoders, 213 = 8192 steps are coded if there are 13 tracks. One-step (grey) code is the code that is utilised. This keeps scanning mistakes at bay. There is no need to travel to a reference point once the machine is turned on because the position value is transferred right away to the control system.

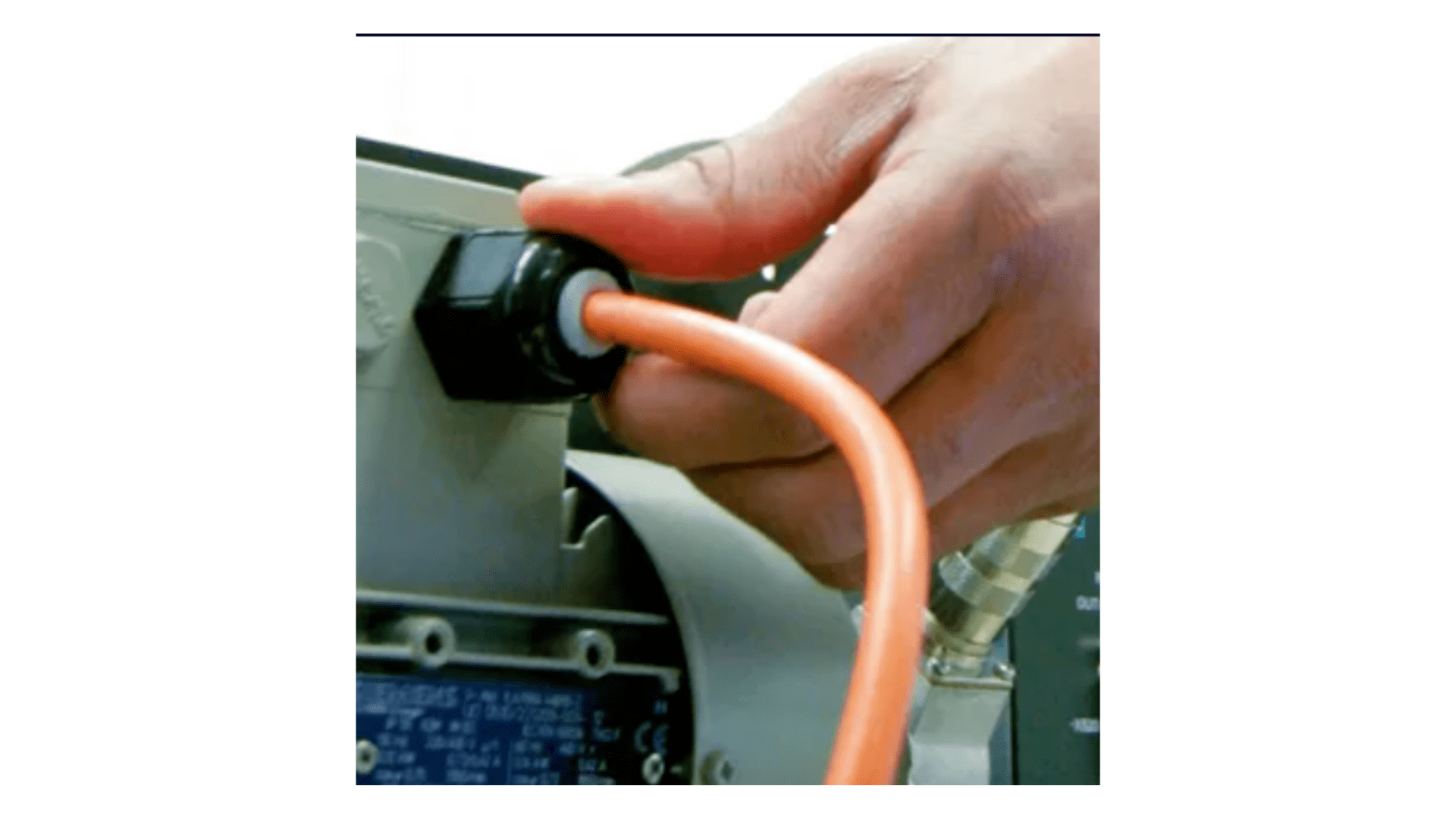

MOTION-CONNECT connection system

Open encoder interface

Thanks to the use of the most advanced connection technology, Siemens’ extended range of MOTION-CONNECT cables and solutions are the preferred option for machine tools, production machinery and general applications in motion control. The signal and power cables boast both UL-CSA and VDE certification and are specially designed for servo motors, induction motors and direct-drive motors for motion control applications and systems tested with Siemens motion control systems and drives.

Benefits

- Reliable system performance

- User friendliness

- Flexibility

DRIVE-CLiQ open encoder interface

An open encoder interface is DRIVE-CLiQ. This implies that users can select measuring systems that are ideal for the tasks at hand. DRIVE-CLiQ can also be used to connect encoders that make use of novel measurement techniques, such as lasers, magnetostrictive sensors, and magnetic/inductive systems.

Motor and encoder data are automatically programmed into the drive when DRIVE-CLiQ is used. Errors are avoided and programming time is saved.

It also makes it possible to incorporate measuring systems—that is, systems with features and prices specifically designed for the application—into the SINAMICS driving system.

DRIVE-CLiQ for measuring system manufacturers

Encoder manufacturers have the option of providing linear or rotary encoders with a DRIVE-CLiQ interface. For implementation with Siemens.

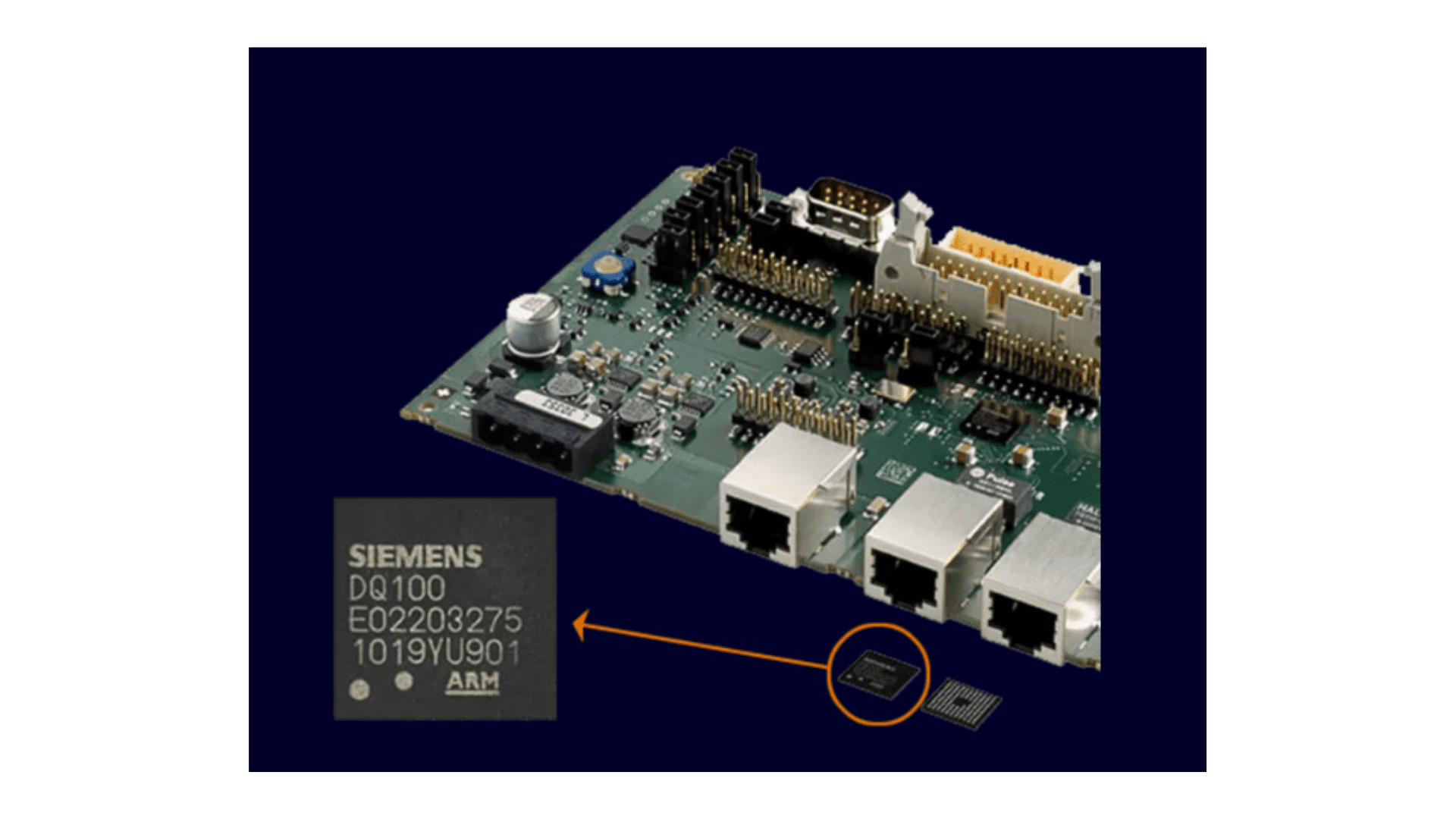

- ASIC DQ100 interface – provides DRIVE-CLiQ functionality. The encoder has direct access to the DRIVE-CLiQ system interface as a result of being integrated into the encoder electronics. The circuits can be ordered in batch sizes of 60, 240 and 1,200.

- Development kit for developing and testing – for developing DRIVE-CLiQ encoders. Comprises a DQ100 evaluation board, driver software and documentation. DRIVE-CLiQ interface software can be developed using the DQ100 evaluation board, whatever driver software and documentation is used.

- Support and certification

The Siemens Support Center provides support for the integration of the DRIVE-CLiQ encoder interface and certifies the DRIVE-CLiQ measuring system.

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.