Geared Motors for Innomotics

You’re guaranteed to find the ideal product for your requirements thanks to our wide selection of geared motors. You will gain most from the new Innomotics Geared Motors’ capacity to provide the maximum degree of flexibility because of their small design, complete adaptability, and large selection of gear units. In addition, we offer servo geared motors for Motion Control uses.

Converter world motor Innomotics

The new Converter World Motor Innomotics, which is completely compatible with SINAMICS frequency converters, is what we are introducing. This geared motor has an efficiency class of IE3, is designed to operate with a converter, and comes in power ranges of 0.37 kW to 55 kW. It is referred regarded as a “world motor” since all major international certificates of approval are compatible with its single motor winding. The motor is designed to operate at its peak efficiency at all line voltages, ranging from 380 V to 480 V. It goes without saying that it is integrated with products like Drive Technology Configurator, TIA Selection Tool, and TIA Portal.

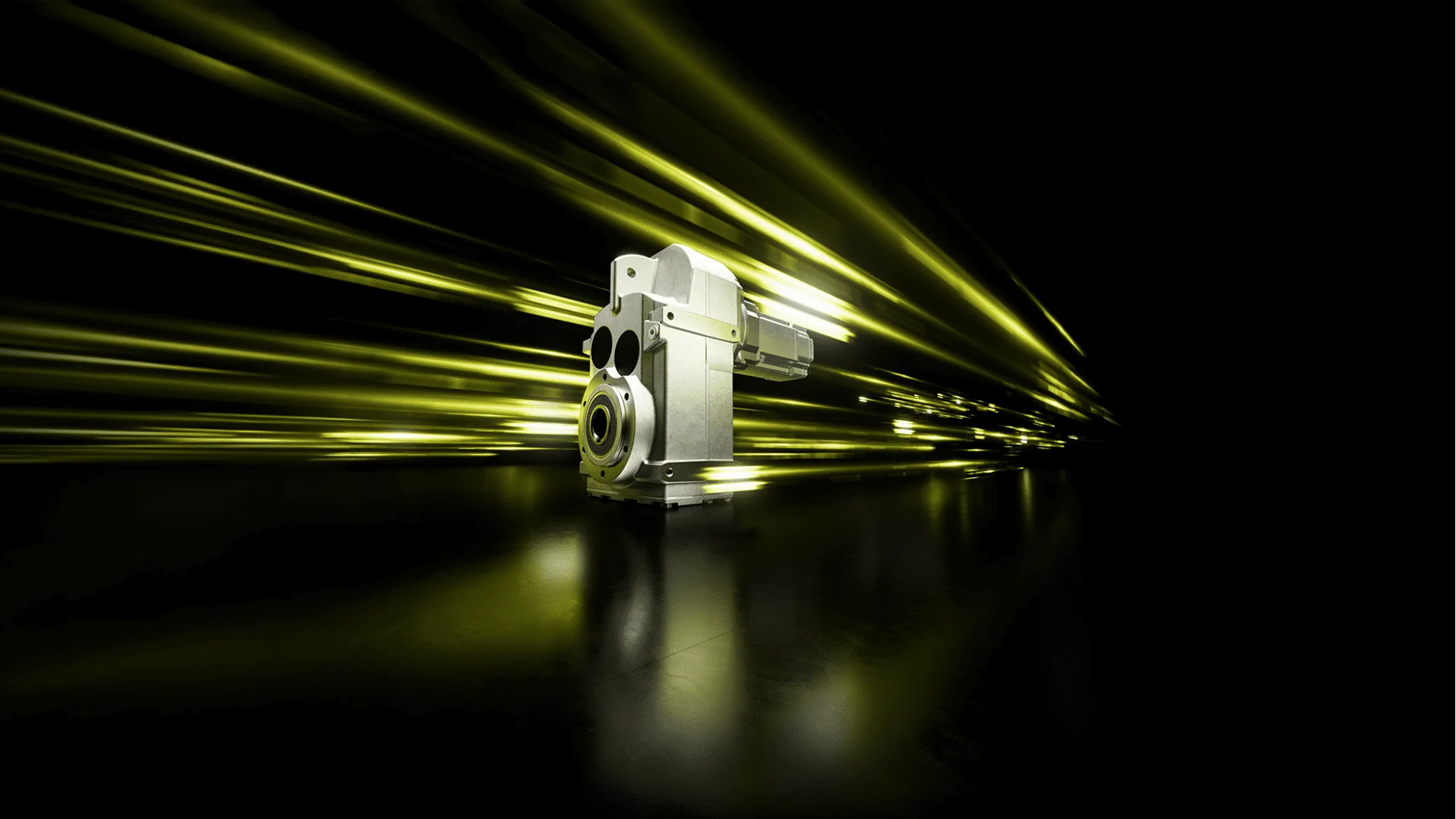

Innomotics Geared Motors

Our geared motors are made to be as flexible and user-friendly as possible. We provide drive systems with optimal performance, including high power density, high gear ratios, high energy efficiency, and precision torque scaling.

Innomotics Motor systems

With the wide range of geared motors offered by Innomotics, you can always find the ideal geared motor to fit your exact needs. We’ve added even more to our offering: the TIA Selection Tool now allows you to pair Innomotics gearboxes with a larger selection of Innomotics motors to create a single, comprehensive package that solves all of your problems. The programme makes it simple to configure the entire system because it calculates and approves every possible motor combination based on factors like mechanics, geometry, and temperature conditions. This one-package solution has an easy ordering and delivery process.

- The TIA Selection Tool (desktop/offline version)

Innomotics explosion-protected geared motors – Available now in an integrated version.

Geared motors with explosion protection from Innomotics can be used in dangerous areas. These locations place a high value on safety, and these effective motors can function safely in harsh conditions for extended periods of time. Based on robust, high-end motors that have been tried and tested all over the world, they are reliable. The end product is a seamless line of motors that meet client needs while maintaining the highest levels of operational efficiency and safety. We have added an integrated version to our array of explosion-proof products, eliminating the need for an adaptor. An adapter between the motor and gearbox is not needed for applications in Zones 2 (gas) and 22 (dust), which reduces complexity and facilitates dimensioning and selection.

- Brochure: Innomotics – explosion-protected geared motors (former known as SIMOGEAR explosion-protected geard motors)

Innomotics reluctance geared motors geared motors

Reluctance geared motors innomotics geared motors

Because of its synchronous-reluctance solution, they are simple to service, making them a great option for a high-energy-efficiency drive system.

Comparing the synchronous-reluctance solution to conventional asynchronous motors reveals numerous significant technological advantages as well as application across a wide range of domains. In addition to being able to attain a high permanent overload in the upper speed range, these motors maintain a steady speed even in the absence of an encoder.

The system is typically used to control roller, chain and belt conveyors in airport baggage and cargo handling facilities. It is also a great fit for warehouses and distribution logistics including packaging and mail handling areas. It is commonly used in hoisting equipment, scissor lift tables and monorail conveyors as well as for skids used in the automotive industry.

Innomotics KS Adapters

By releasing a new coupling adapter made specifically for SIMOTICS servomotors, Innomotics broadens its selection of servo geared systems. This adaptable system makes it possible to connect designated SIMOTICS servomotors to a variety of Innomotics gear unit types. It is both small and versatile. Handling is made much simpler by this method, which links different gear unit types to different SIMOTICS servomotors instead of requiring a unique adapter for each motor. Shorter downtimes and lower costs due to easy installation and removal, optimised stock management, and a backlash-free design that enables attachment with no feather key as standard for high-precision are some of the advantages of the adapter solution itself.

- Brochure: Innmotics Geared Motors KS adapter – Simplified handling for high-precision applications (former known as SIMOGEAR Geared Motors KS adapter)

Geared motors for all production areas

Innomotics Helical Geared Motors

Shank pinion allows helical geared motors to achieve large gear ratios. In addition to having very economical performance, they have remarkable energy efficiency (98% per stage). furthermore offered in a high power level. They come in foot and flange-mounting versions with solid shafts, and one, two, or three stages. Among other applications, Innomotics helical geared motors are used in conveyor belts, packaged goods transportation, and vertical conveyors.

Innomotics Geared Motors

The geared motor solutions that Innomotics provides are small, adaptable, and best fitted into the drive train. Consistently forceful and accurate. The industry expects more power, more flexibility, and a more consistent approach, particularly in the area of conveyor technology.

Performance of an Innomotics gear motor ranges from 0.09 kW to 55 kW. With helical, parallel shaft, helical bevel, and worm geared gear units, among other types and sizes, it may attain a gear unit torque of up to 19.500 Nm. The geared motor from Innomotics is compatible with many other geared motor vendors because it complies with the current regulations. The new series of Innomotics geared motors is 1:1 compatible to the general standard in the market, and can therefore be simply integrated into existing or new machines and systems.

Innomotics Bevel Geared Motors

In addition to having high gear ratios, bevel geared motors have very high energy efficiencies—98% per stage. They have a high power density and can reach high gear ratios. They can be utilised in locations with defined spatial conditions even in narrow buildings. They are available in foot or flange mounting versions with solid or hollow shafts in stages two and three. Bevel-geared motors manufactured by Innomotics are utilised in carriage drives, rope lifts in warehouse operations, and conveyors for moving goods.

Innomotics parallel shaft geared motors

Narrow construction spaces can also be effectively utilised with parallel shaft geared motors. Their energy efficiency is impressive, with 98% of it being used for each stage. The plug-in pinion allows Innomotics parallel shaft geared motors to achieve large gear ratios. Can a hollow shaft be positioned on both sides? They are attached using a foot, flange, housing flange, or shaft mounting with torque arm, and they have two or three stages. Solid shafts, hollow shafts, splined hollow shafts, and hollow shafts with shrink discs are the available options. They are commonly utilised in vertical conveyors, shelf access devices, agitator drives, and carriage drives.

Innomotics worm geared motors

Worm geared motors are an affordable option, particularly for low power levels, and are incredibly quiet. Because of their compact shape, they can be employed in narrow locations and attain high gear ratios. Versions with foot or flange installation are available, and they come with one or two stages. Worm geared motors from Innomotics are distinguished by their SIMOLOC keyless tapered hollow shaft locking system. They are available with hollow or solid shafts. Typically, these kinds of motors are utilised for rope lifts, tiny conveyor belts, and other conveyor systems.

Innomotics Helical Worm Geared Motors

Two-stage versions of helical worm geared motors are available. The mounting selection consists of both hollow and solid shafts. Since they use less energy, they are frequently selected for drives that include angular geared motors. Worm gear stage allows for the implementation of high ratios. For angular geared motors in the lower torque range, Innomotics helical worm geared motors are an affordable option. They are utilised, for instance, in waste water systems and movie theatre drives because they produce incredibly little noise.

Innomotics Geared motors with motor integrated frequency convertors.

The SINAMICS G115D is a full drive system, not merely a new distributed drive. The SINAMICS G115D comes in two versions and includes a gearbox, frequency converter, and motor. With features specifically designed for conveyor applications, this user-friendly, modular, and adaptable solution has a unique design that makes commissioning, servicing, and joining up a breeze. You can take use of SINAMICS G115D’s innovative design for effortless handling, quick setup, and incredibly straightforward operating. Because it is an all-in-one solution, integrating it into current automation environments is simple.

Innomotics reluctance geared motors

Particularly under partial load, reluctance geared motors are known for their incredibly great energy efficiency. Its motor efficiency is about the same as IE4. With the help of the synchronous-reluctance solution, they are quite simple to service. Even without an encoder, they are able to achieve exact speed. In the high speed range, a high permanent overload is achievable. Comparing the synchronous reluctance method to a conventional asynchronous approach, there are significant technological advantages and application possibilities in numerous industries. The Innomotics reluctance geared motor is especially well-suited for applications requiring excellent energy economy in general equipment systems and conveyor technology. When combined with the appropriate converter, the portfolio is quite large. The method is commonly employed in luggage and cargo handling facilities at airports for rollers, chains, and belt conveyors. It also works well with postal and packing services, warehouses, and distribution operations. It is frequently utilised in rollers, chains, belts, skids, and scissor lift tables, as well as in monorail conveyors, hoisting gears, and the automotive sector.

Gears with motor adapter

The Innomotics series is offered with motor adapters allowing the use of other motors in addition to variants with integrated motors. It is possible to mount the entire range of Innomotics motors because of the specially developed traction group. Both synchronous and asynchronous motors can benefit from that. The newly designed short coupling adapters enable the provision of the appropriate geared motor for any given application. At the moment, Innomotics adapters consist of:

- IEC motor adapters – there are two possibilities for the mounting of IEC standard motors. We suggest the short adapter K4 for universal use and the coupling adapter K2 for more sophisticated use. The adapters can be mounted on all types of Innomotics geared motors and are in accordance with the dimensions of the IEC standard flange (B5).

- NEMA motor adapters – there are two possibilities for the mounting of NEMA standard motors. We suggest the short adapter K5 for universal use and the coupling adapter K3 for more sophisticated use. The adapters can be mounted on all types of Innomotics geared motors.

- Motor adapters for servomotors – the adapters for servomotors are based on two versions. The first one is the KS adapter available for SIMOTICS S-1FL6, S-1FK2, S-1FK7, S-1FT7, M-1PH8 and is extensively widening the Innomotics drive system portfolio for the servomotors. The second type is K8 adapter available for SIMOTICS M-1PH8 main motors.

Servo geared motors

When developing SIMOTICS S-1FG1 servo geared motors, special emphasis was placed on the optimum coordination with the SINAMICS S120 drive systems. Motors, converters and commissioning tools are optimally coordinated and harmonized with one another. The system can be quickly commissioned as a result of the electronic type plate and the fact that the motors are connected via the DRIVE-CLiQ system interface. Prefabricated MOTION-CONNECT signal and power cables mean that the components can be simply and perfectly connected with one another.

- More info about SIMOTICS S-1FG1

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.