First choice for maximum dynamics and precision

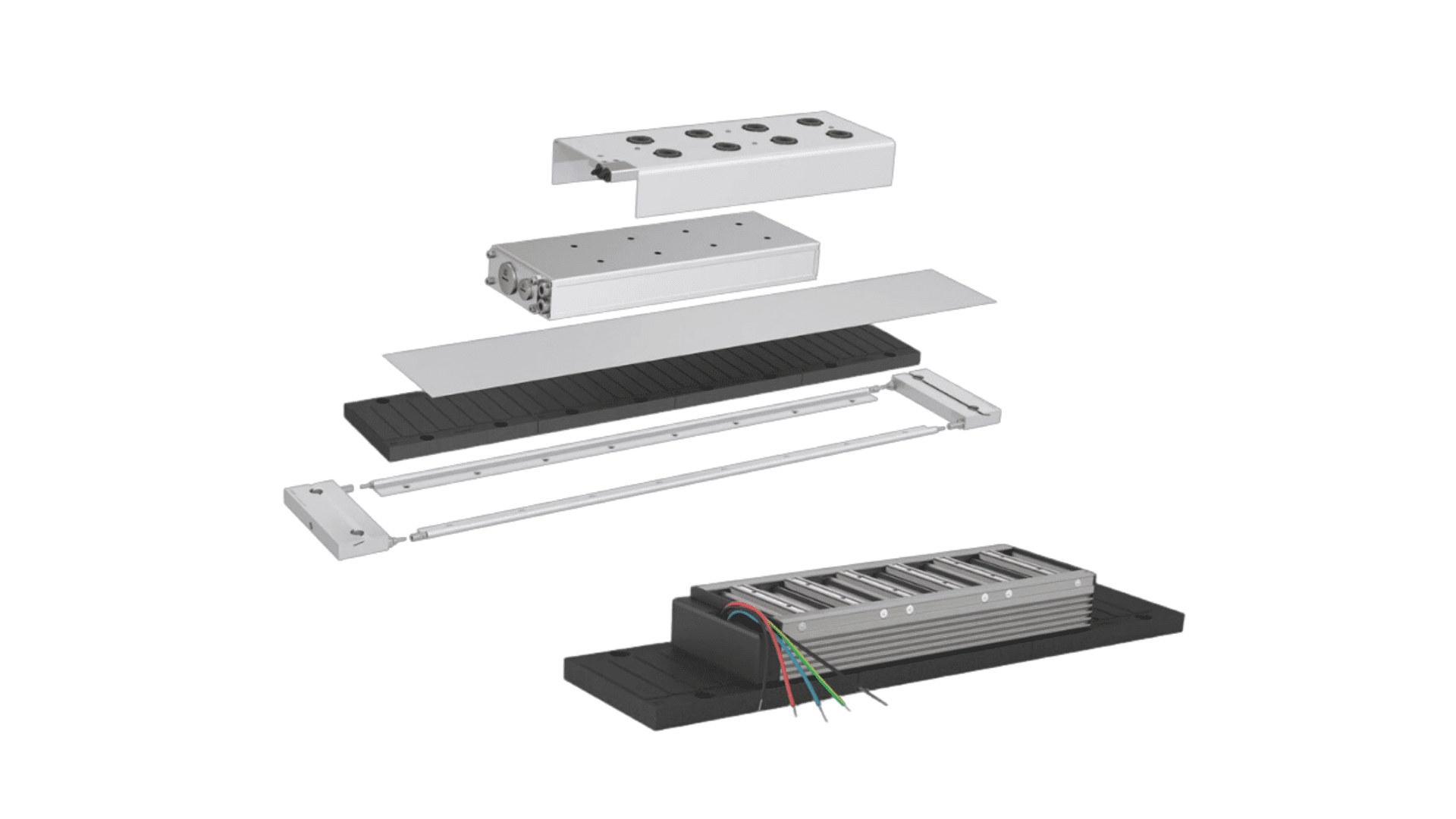

The SIMOTICS L-1FN3 motors are linear drives in compact design with high power/force density. Due to the wear-free power transmission, the motors meet the highest requirements for dynamics, contour accuracy and precision. Together with the SINAMICS S120 drive system, the motors are optimized for operation on high-performance machine tools and production machines.

SIMOTICS L-1FN3 – the modular industry standard

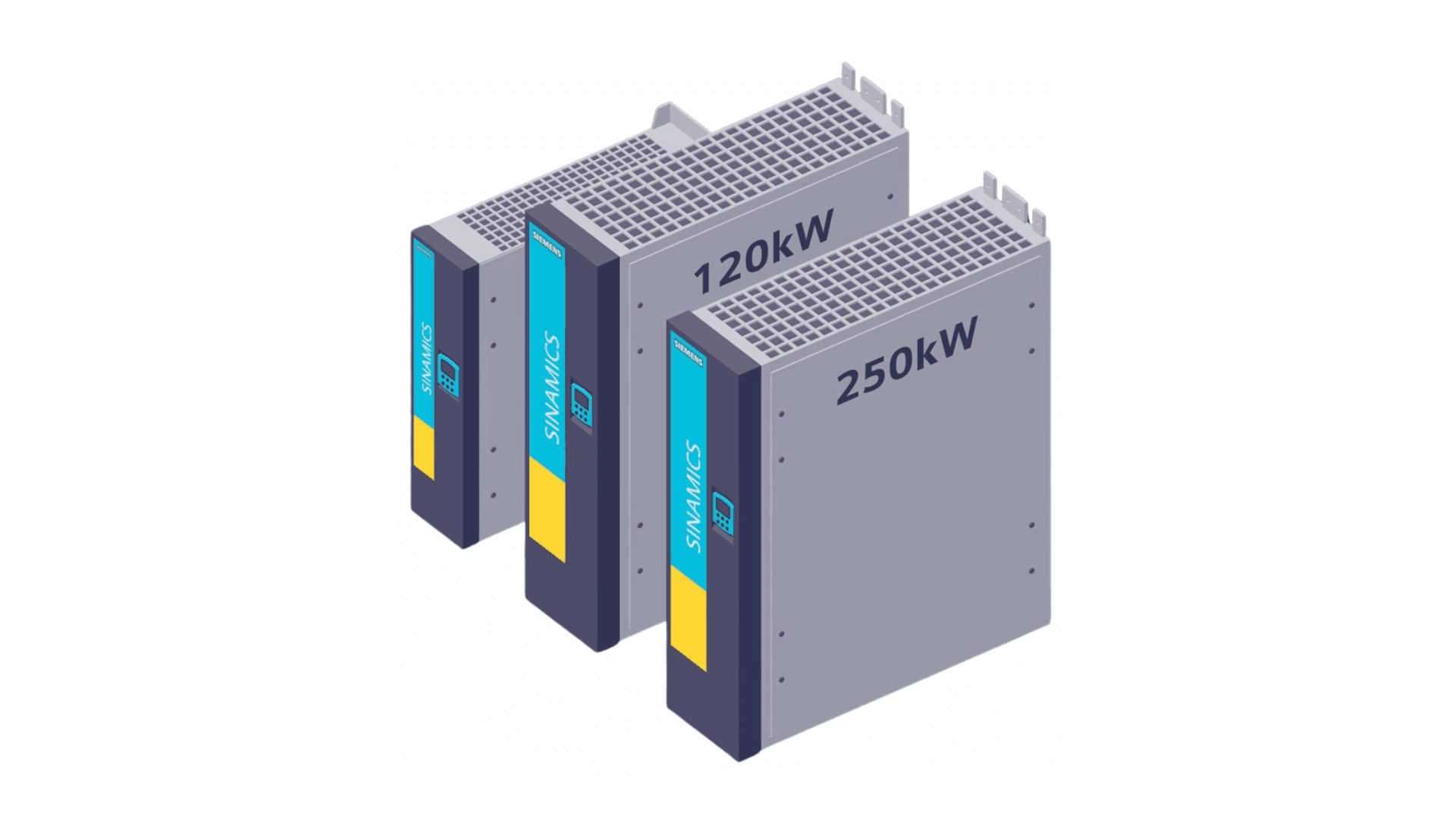

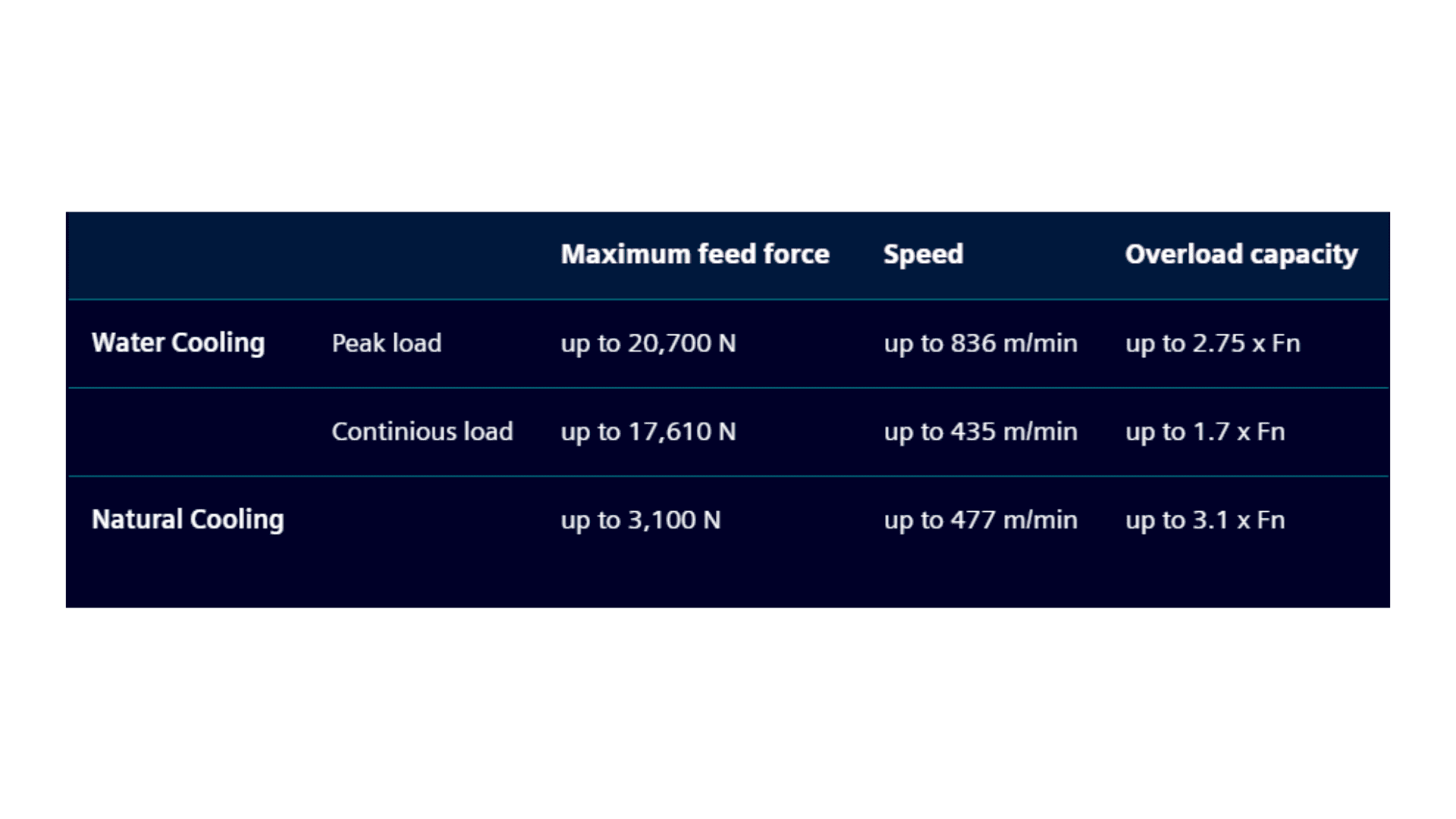

The tried-and-true standard for linear motion for many years is the SIMOTICS L-1FN3 linear motor, which was designed specifically for use in machine tools. You can choose from a wide variety of motor versions that are almost wear-free and require no maintenance thanks to its modular design. There are two variants of the water-cooled SIMOTICS L-1FN3 motors available: one for peak load operation and the other for continuous load operation. They come in multiple action kinds and seven various widths, with a total length variation of up to five. SIMOTICS L-1FN3 motors, which are naturally cooled, come in three width options, three length options, and multiple action types. SINAMICS S120 converters are intended to be used with the motors during operation.

Version for peak load

Use in machine axes that are accelerated for short periods or when high forces are required for short periods.

Typical applications:

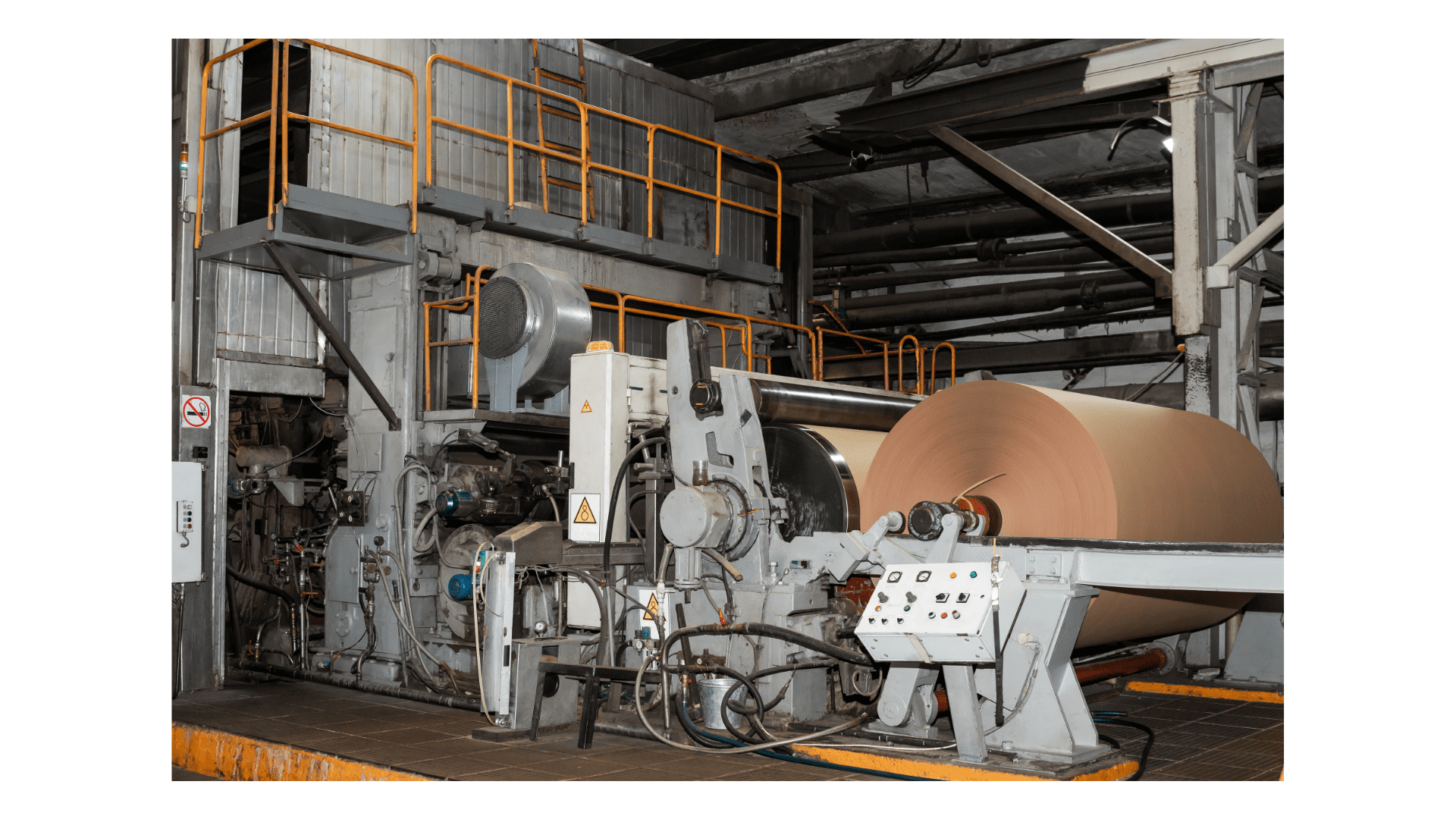

- High-dynamic, flexible machine tool and production machine construction

- Laser machining

- Handling

Version for continuous load

Use in machine axes with constant acceleration changes, with high process and weight forces or during operation without water cooling.

Typical applications:

- Grinding

- Non-circular machining (e.g. oscillating applications)

- Z axes without weight compensation, quills

- Handling, Cartesian robots

With a linear motor, every movement sits perfectly

The benchmark for directly driving linear axes

The main advantage of linear direct drive technology is the extensive avoidance of the effects of elasticity, play, and friction, as well as natural oscillation in the drive train. This results in a higher dynamic response and increased precision.

Highlights:

- Highest precision linear motion with high dynamic performance

- Enormous force density in a compact design

- Highest traversing velocities for all applications

- Large air gap, therefore extremely rugged against external influences

- Wide range of options depending on the application profile

- Wear-free drive components

- Low lifecycle costs of machines

Typical applications SIMOTICS L-1FN3 water-cooled linear motors

- Milling, turning and grinding machines

- Laser machining centres

- Handling systems

- Oscillators

- Test setups

Typical applications SIMOTICS L-1FN3 naturally cooled linear motors

- Handling Axes

- Feed Axes

- Wood Machining

- 3D printing

- 2D/3D handling portals

- Laser Cutting/ Water Jet Cutting Machines

- Placement Machines

Technical overview

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.