Alpha Drives Control System Upgrade for Sewerage WWTP

The system implemented seamlessly orchestrates every stage of the process, commencing from the Inlet screens, which are meticulously serviced by two gravity-fed sewers. It guides the progression through a series of meticulously coordinated steps, including screen conveyors, compactors, grit separators, and the pivotal washpactor.

Facilitating intuitive control and monitoring, the Simatic HMI interface empowers operators with an array of functionalities. This includes comprehensive management of Flow meter totalizer readings, categorized into daily, weekly, and total accumulations, as well as meticulous monitoring of kWhr pulse statistics across varying timeframes, spanning from daily snapshots to cumulative totals.

Furthermore, the HMI facilitates insightful trending analysis, charting the dynamic fluctuations of both flow rates and kWhr consumption over time. Instrument Pages within the interface grant access to fine-tuning parameters, adjustment of setpoints, and meticulous scaling to ensure optimal operational performance.

Alarm and Event pages provide a comprehensive log of all system alerts and events, offering operators the ability to swiftly respond to anomalies and configure dial-out numbers for automated notifications. Through this integrated control system, operators can effortlessly oversee and optimize every facet of the wastewater treatment process, ensuring efficiency, reliability, and regulatory compliance.

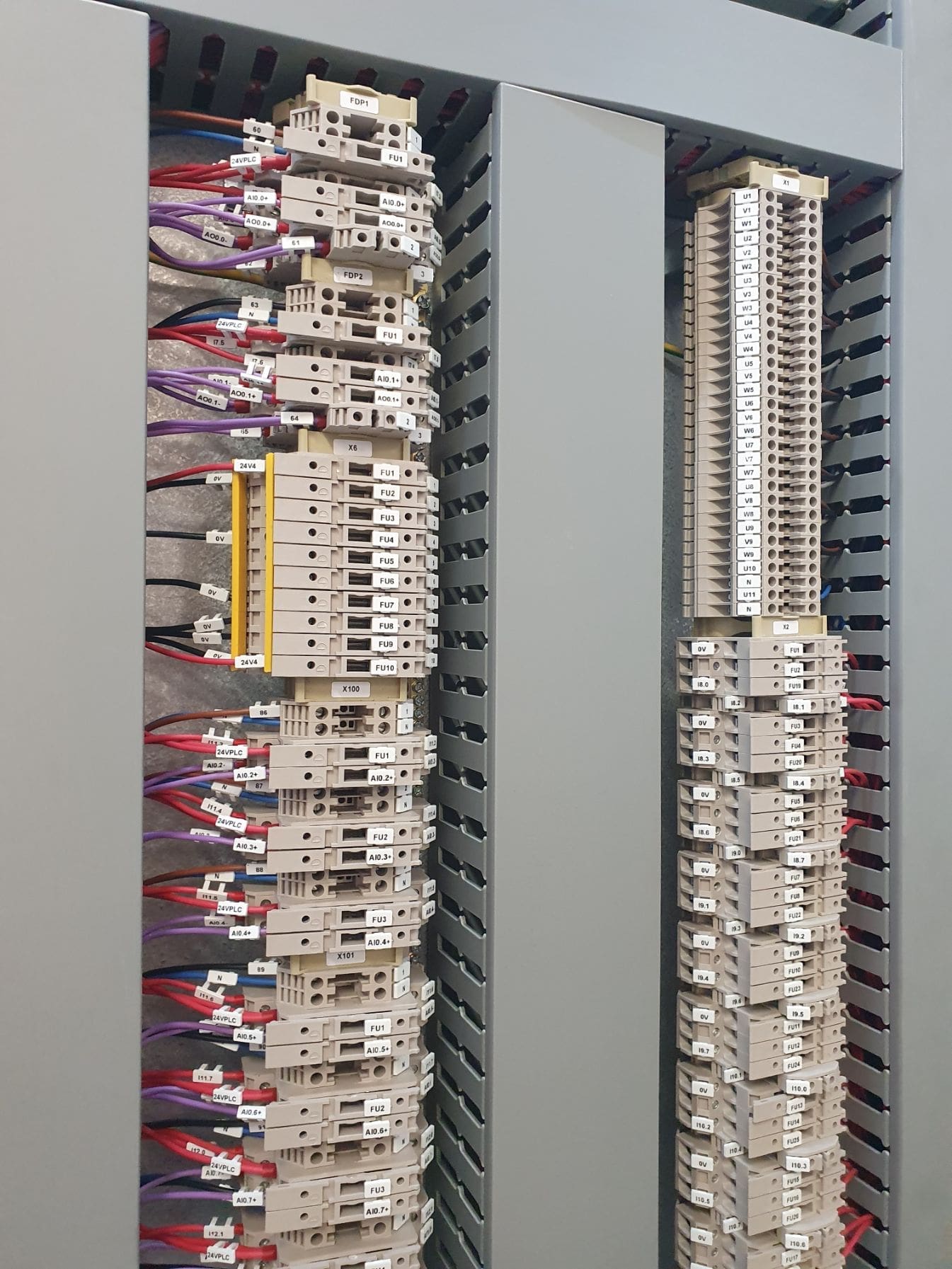

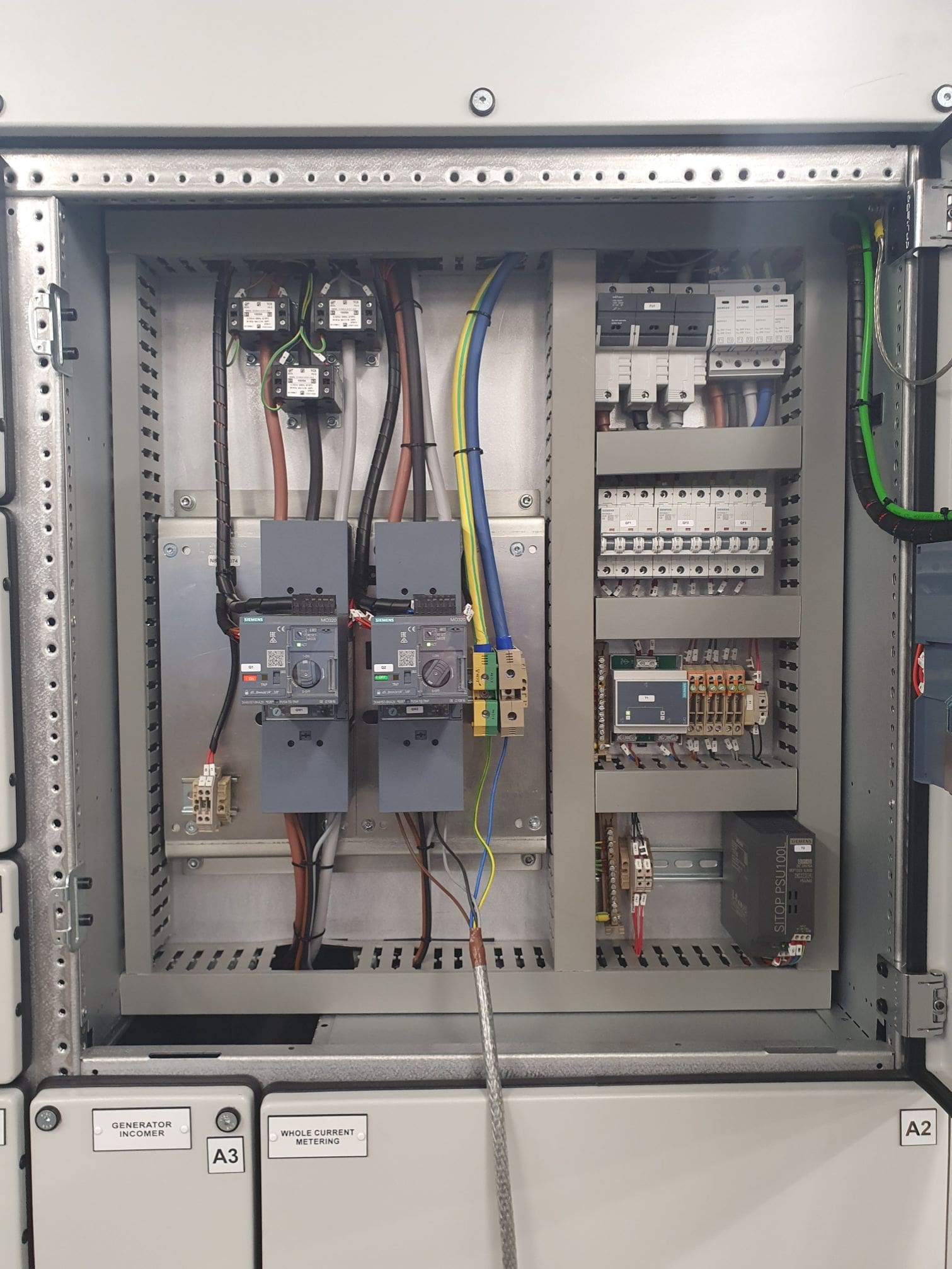

Hardware Included:

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.