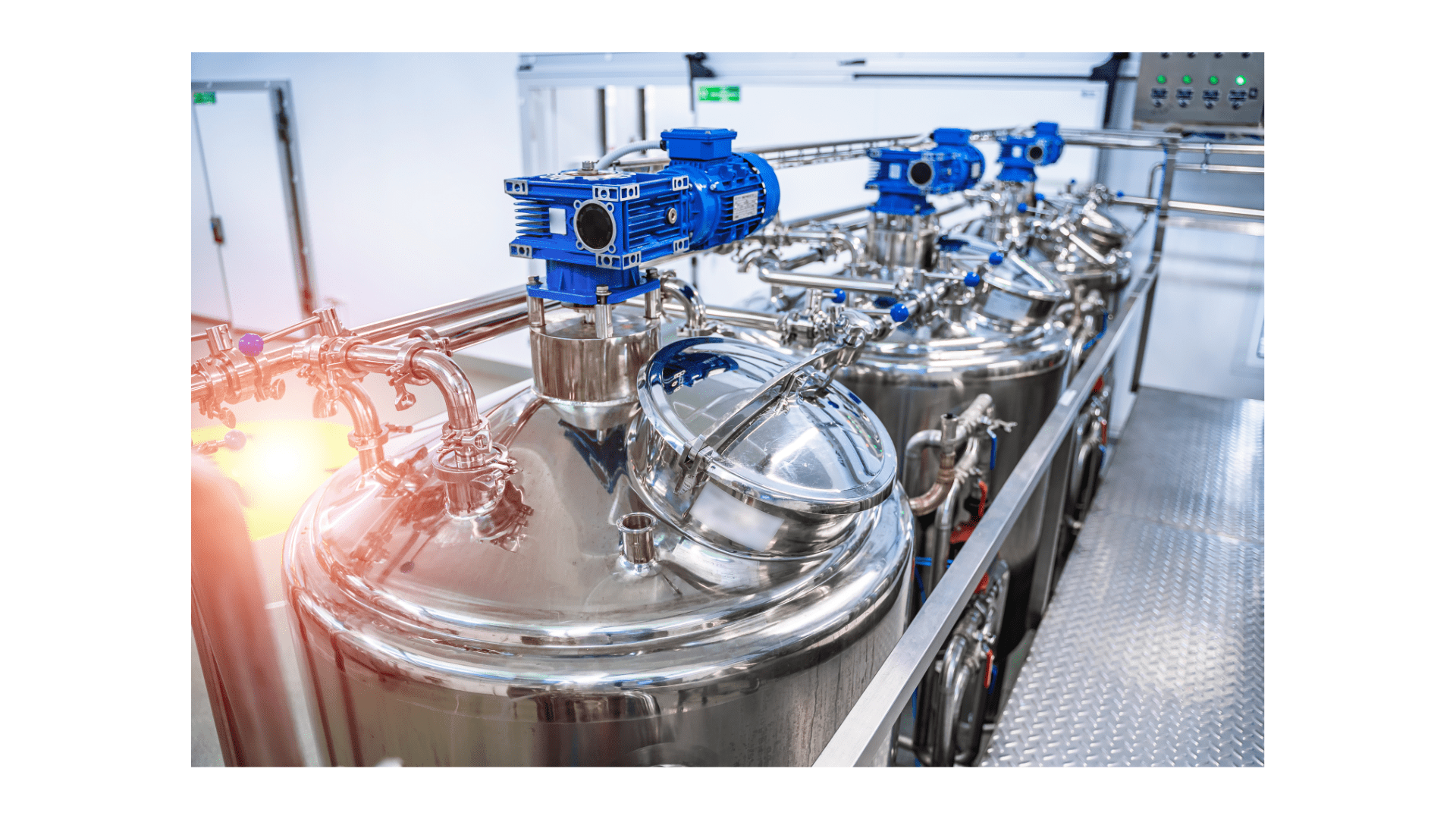

Increased Adaptability On The Way To Producing More Customised Goods

The dairy industry is known for its mass manufacturing and extreme cost sensitivity, but the market is also being shaped by creative packaging and an expanding range of flavours. Digitalization is giving the dairy industry new opportunities to optimise the entire value chain in order to meet all general and consumer criteria. Drawing from our vast array of customised goods, systems, and solutions, we

Learn About Our All-Encompassing Strategy For The Dairy Sector.

We use a comprehensive approach, combining cutting-edge automation solutions, cutting-edge software concepts, and tailored finance offerings to produce a comprehensive package that boosts your productivity, sustainability, and competitiveness.

1. Comparative Analysis

The Food and Beverage Industry is seeing novel issues in the intralogistics domain, mostly due to the swift expansion of e-commerce.

Flexible, scalable intralogistics systems with maximum reliability and availability are needed to handle growing inventory turnover rates with ever-shorter storage periods, small order quantities with quick delivery times, rising return rates, and increased delivery volumes on short notice.

2. Eco-Friendly Packaging

High material and energy consumption was standard. The products are wrapped in an incredibly thin, highly elastic stretch film using a method known as orbital wrapping, which makes use of cutting-edge cold wrapping technology. The outcomes are striking: a 90% reduction in energy usage, 70% less plastic, and 40% less cardboard.

Significant numbers that translate into a 70% decrease in the total carbon footprint. In addition, the film’s production material was created to be up to 100% recyclable, which makes the idea of a more circular economy attainable.

3. Astute Loaning

At Siemens, we can assist you in determining which technology best suits your requirements and your financial situation. With its cutting-edge array of financing options, Siemens Financial Services spares you from having to spend your valuable capital.

These solutions can be adjusted to include any extra requirements, such as software, maintenance, and support, and can be designed to accommodate your specific cash flow requirements. Our goal, which we refer to as “smart financing,” is to maintain a positive cash flow.

4. Cybersecurity

The increasing digitalization and networking of industrial systems and machines also means a higher vulnerability to cyberattacks. Facilities that serve soft drinks are not an exception; taking the necessary precautions is essential. To fully defend industrial facilities from both internal and external cyberattacks, a multilevel strategy covering all bases at once is necessary, from access control to copy protection, from the operational to the field level.

As advised by the international standard IEC 62443, Siemens offers a multilayer security concept called “defence in depth” that offers plants both all-around and in-depth protection.

5. IT/OT Integration

Integrating horizontally and vertically entails dismantling information silos and making use of all the data an organisation produces. Networks for Information Technology (IT) and Operational Technology (OT) must work together smoothly for the best use of the data produced in production. To do this, we have combined all necessary technologies into our Totally Integrated Automation (TIA) approach.

6. Plant Efficiency And Maintenance

Manufacturers of food and beverages are realising more and more how important it is to process production data even more extensively.

Siemens can assist your company in gathering, connecting, and transforming data from a variety of sources into insightful knowledge that will enable you to monitor and control your operations. By linking this data, it is possible to take a precise performance snapshot, which opens the door to root cause analysis and speeds up production improvement. In addition, Siemens offers a wide range of products that assist condition-based maintenance, which guarantees the plant’s effectiveness.

7. Sustainability

The food and beverage sectors of today face enormous obstacles in their quest for cost-effective, high-quality, climate-neutral production.

We assist our clients in optimising their buildings, production facilities, auxiliary installations, and power consumption by helping them increase productivity while advancing their sustainability goals. We are helping them to provide wholesome, high-quality food and drinks.

8. Standardization

Digitalization is predicated on standardisation. Siemens presents an integrated solutions, data interfaces, communications, and technology standardisation model.

For instance, a standardised, user-friendly Line Integration System that integrates equipment from the same or various OEMs and offers performance visualisation, monitoring, and operational authority might be used in the soft drink business.

This system provides a notion that complies with Weihenstephan and OMAC User Group specifications while supporting OPC UA.

9. Tracking And Tracing

Product genealogy

A product’s history can be compiled by using Opcenter Execution Process to record material movements. Transparency throughout the production process guarantees the validity of sustainability claims for labour and human rights.

Trusted traceability

Products in the food and beverage sector can now be transparently traced from the field to the kitchen, thanks to blockchain technology. See how we use this technology in conjunction with the IoT OS MindSphere to allow full traceability for the F and B industry by reading our white paper.

10. Simulation

Throughout the production lifecycle, processes can be tested with Siemens’ digital simulation technologies to better understand “what if?” scenarios and maximise capacity. Manufacturers can predict and analyse performance and identify improvements before making additional financial commitments by building an accurate virtual model of a product, process, or production plant.

11. Adaptable Recipe Management

Even the biggest food and beverage factories require an efficient process automation system?

Here it is: SISTAR provides all the features you need for mixing and creating recipe-based soft drinks in an intuitive and accurate manner. You have complete transparency with SISTAR. You can always get up-to-date reports with SISTAR. Additionally, you can benefit from a fully established MES/MOM solution with the optional link to SIMATIC Opcenter.

Utilise Technology To Overcome The Complexity-Related Issues Faced By Dairy Farms.

Learn About The Digital Threads In The Dairy Sector

An essential component of our Digital Enterprise strategy is Digital Threads. From product creation to tracking the finished product, all five threads are anchored in one of the Digital Twins. Regardless of the size and market of the business, the Digital Threads assist in resolving the most significant client issues. They can be applied separately to every business, beginning at the point of value creation.

1. Smart Product & Process Design

Create the conditions for ongoing innovation

The beverage and the packaging are two examples of the product in the food and beverage sector. The process of creating a new product calls for multidisciplinary design. Development may be sped up by creating a link between beverage and package R&D and manufacturing through Smart Product and Process Design. Continuous innovation is built on the foundation of simulation, validation, documentation, and global utilisation of virtual assets.

Quicken the pace of innovation

Using a range of simulations, from several production facility simulations to product-performance simulations, stay abreast of market trends and virtually validate new goods.

Quicker transition from laboratory to production

Thanks to close coordination between R&D and manufacturing, shorten the time from lab to practical manufacturing.

Reduced time from concept to shelf

Because of the optimized operations throughout the whole value chain, less time is needed overall to go from ideation to retailers.

2. Product Design And Optimization

Adjust to evolving needs

In the virtual environment, Product Design and Optimisation facilitates the validation and commissioning of new facilities or the modification of existing ones. This facilitates the exploration of numerous options and saves a substantial amount of time and money, as seen, for instance, with Digital Twins and the Module Type Package industry standard. Virtual reality can also be used to verify that humans and robots can work together to create ergonomic work environments.

Adopt new technology with ease and grace.

Use the advantages of the virtual world to create and manage a representation of production assets. Specific plant capabilities can be defined, modular lines can be engineered, and the necessary flexibility can be fully enabled.

Quickly balance output and demand

Adapt production flexibly to the ever-changing needs of the customer.

3. Flexible Manufacturing

fusing the virtual and physical worlds

With the correct technology, shop floors can seamlessly shift from the digital world of design, engineering, and simulation to efficient operation management and automated execution. This is made possible by flexible manufacturing.

Appropriate management of operations

Throughout the production process, optimise scheduling, quality control, and order orchestration for every order.

Plug-in and generate

Integrate new equipment into your production as soon as possible. Flexibility can be increased by adding new hardware modules that interface with current modules with simplicity.

Introduce novel technology

Without having professionals on site, update automation and machinery and add new features for a new process or product by using technologies like edge

4. Traceability And Insights

Acquire knowledge and continually improve output and products.

Utilise the newest technology to collect information and get fresh insights. Edge and cloud analytics facilitate predictive on-site and remote equipment maintenance as well as a deeper understanding of a plant’s performance. IoT, MindSphere, and Blockchain are the three layers that make up Siemens Trusted Traceability.

Openness and confidence

More and more customers are choosing goods that align with their values. Businesses can increase their competitiveness by demonstrating that they meet the expectations of their customers.

Look for methods to produce superior goods.

Refresh virtual world simulatio

Opportunities From Data That Never End When You Use Siemens Xcelerator To Transform Your Business Into A Digital One.

Businesses may gather, comprehend, and utilise the vast amounts of data generated by the Industrial Internet of Things (IIoT) by evolving into real Digital Enterprises. As a result, industry is becoming more sustainable through constant optimisation in almost real-time, increased transparency, and decreased resource usage. We assist our clients in accelerating their digital transformation to become Digital Enterprises using Siemens Xcelerator, our user-friendly, adaptable, and open digital business platform. Find out what opportunities exist for your business!

Optimize Production Processes Through Modernization That Preserves Liquidity

Why Modernize Now?

- Increase production efficiency

Increase the efficiency of your dairy through better raw material yields, less material loss, and optimized throughput times, and avoid production downtime. - Increase sustainability

Optimize the consumption of energy, water, and chemicals through targeted modernization – for sustainable production and a better CO₂ balance. - Accelerate time to market and protect processes

Respond faster and more flexibly to new market demands through more efficient development and production of new products and easier product changes and protect your dairy from the growing threat of cyberattacks with a holistic approach.