Universal. Precise.Safe

Universal

- Power and closed-loop control performance can be freely coupled thanks to SINAMICS S120.

- Increased adaptability with intelligence for central closed-loop control

- Vector and servo control performance can be flexibly chosen

Precise

- Reduce life cycle costs for systems and plants

- The Totally Integrated Automation (TIA) engineering platform allows for the parameterisation, programming and commissioning of any component without causing any system interruptions

- A wide variety of embedded software is mostly used to implement the functions.

Safe

- Safety integrated is a universal, standardised safety concept.

- STO, SBC, SS1 SS2, SOS, SLS, SDI, SSM, SLP, SP, and SBT are examples of integrated safety functions

- Smooth execution of safety features in compliance with PL d (EN ISO 13849-1) and SIL (EN 61508)

Full flexibility for plant, system and machine concepts

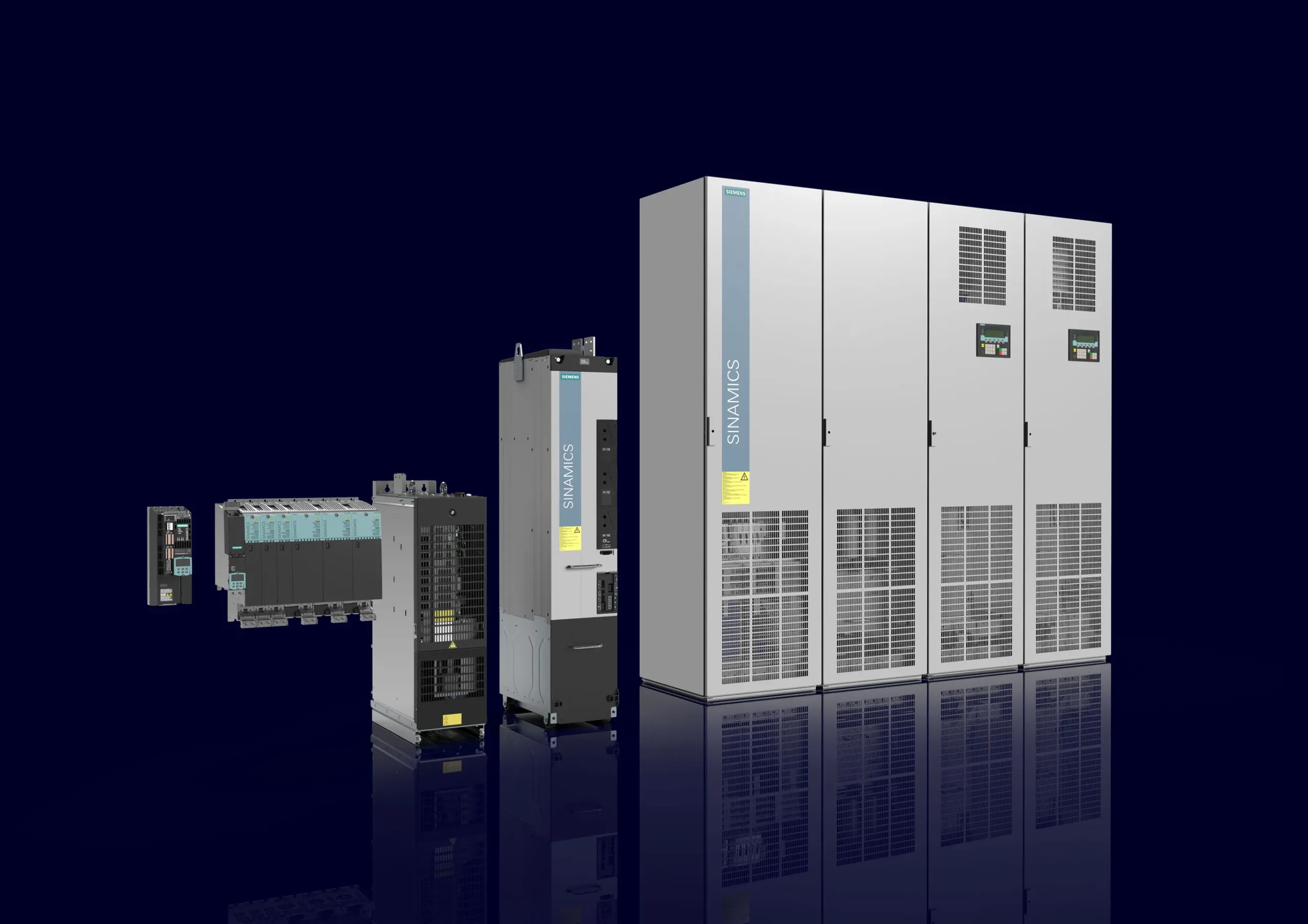

Modular SINAMICS S120 system

SINAMICS S120 Block-size

The small, versatile player for one-axis applications

SINAMICS S120 Book-size

Demonstrated effectiveness in the development of plants and machinery as well as the broadest variety of motion control activities

SINAMICS S120 M

The little drive unit that is ready to connect for distributed topologies

SINAMICS S120 Chassis DC/AC

Powerpacks with liquid or air cooling for multi-axis drive solutions

SINAMICS S120 Chassis-2 DC/AC

The creative solution for multi-axis drive solutions with 315-900 kW of power

SINAMICS S120 Chassis AC/AC

The power modules with liquid or air cooling for single-axis applications

SINAMICS S120 Cabinet Modules

The type-tested cabinet system for multi-motor drives with liquid or air cooling that is ready to connect

SINAMICS S120 Cabinet Modules-2

Our air-cooled modular cabinet system’s next phase combined with SINAMICS S120 Chassis-2’s cutting edge benefits

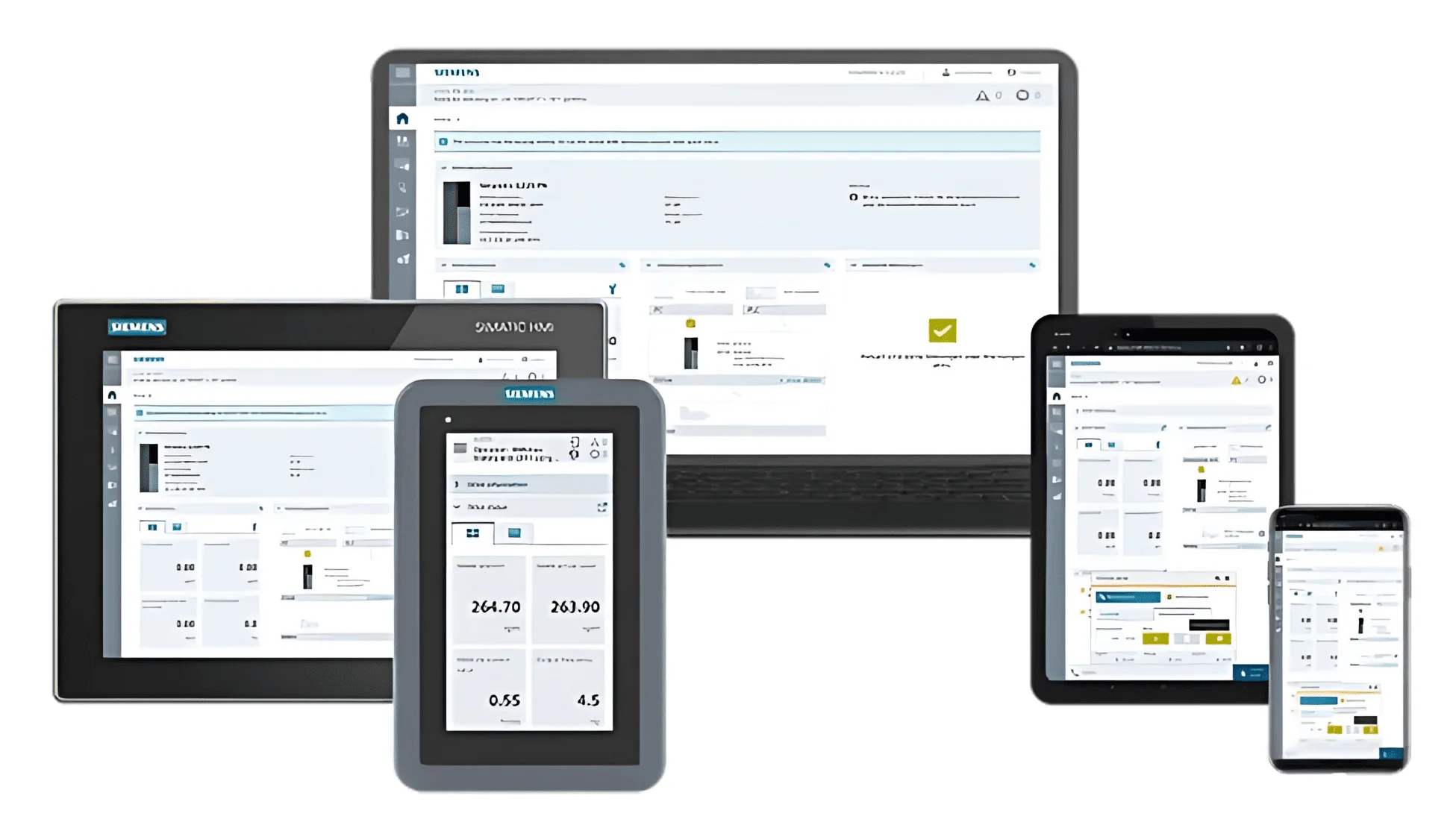

Efficient diagnostics and maintenance – at any time from any place

With the SINAMICS web server, you may access your SINAMICS S120 from any web-capable device, regardless of where you are right now. You can cut expenses and overhead by using the SINAMICS web server for diagnostics, maintenance, or integrating your own webpages.

SINAMICS web server for SINAMICS S120

High efficiency

- A brief summary of the drive’s current configuration and state

- Multiple languages and easily comprehensible plain text are used to display diagnostic information and messages

- Any PC with network connectivity can upgrade the device’s capabilities, either locally or remotely

- A quick and easy summary of useful resources to aid in troubleshooting

Highest flexibility

- The user-defined parameter lists are shown. It is possible to create, manage, and remove parameter lists. All potential cross-axis parameters are listed.

- It is possible to configure users with different rights

- The commissioning tool (Starter/Start-drive) is not required

High degree of user-friendliness

- English, German, Chinese, Italian, French, Spanish

- It is possible to archive machine documentation

- It is possible to store your own logbooks directly on the drive (information can be easily shared between maintenance and service).

In the realm of digital drives, SINAMICS S120

With digital drive data, you can jumpstart a productive future with greater transparency, efficiency, and simplicity as well as reduced effort, errors, and expenses.

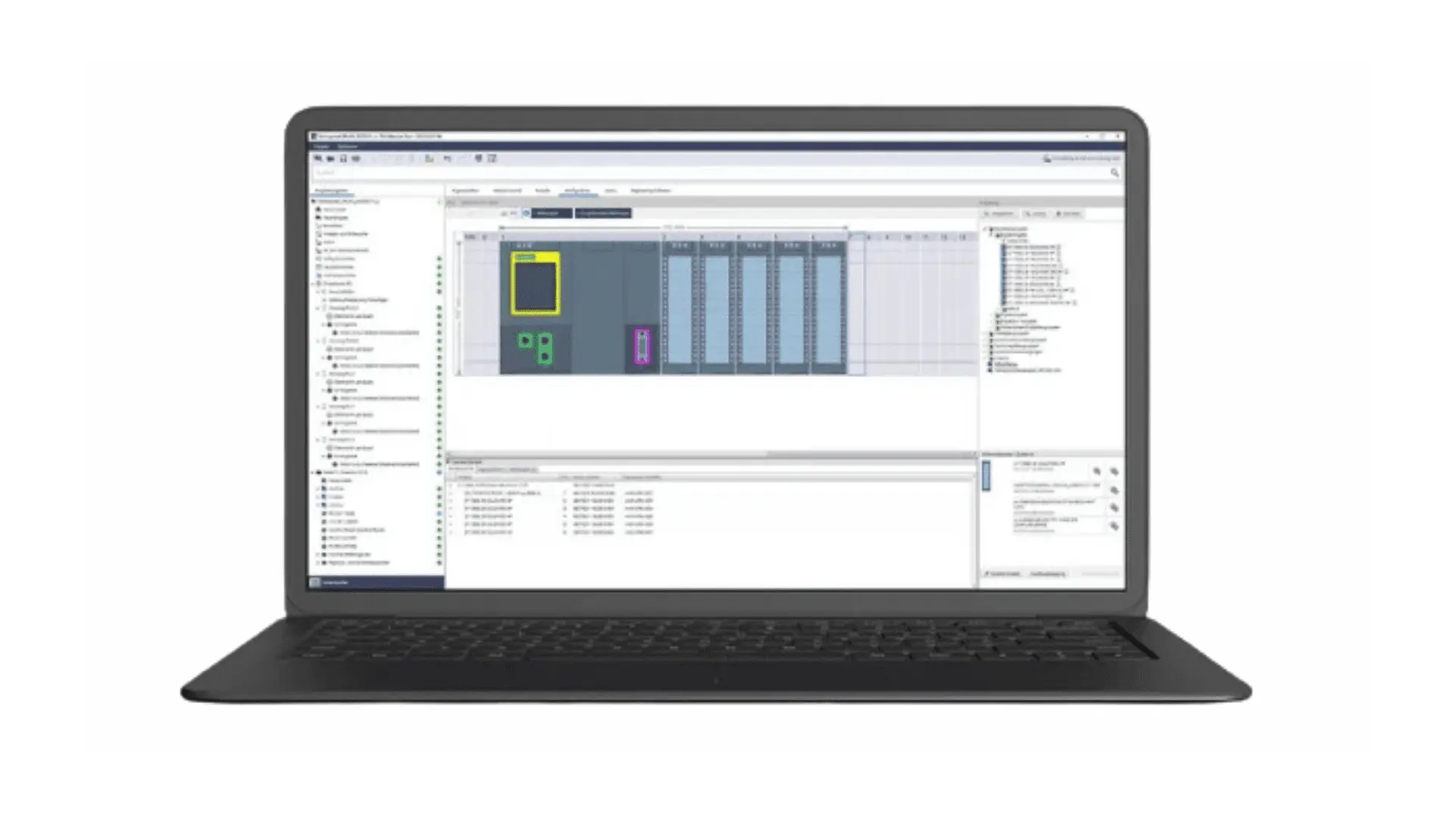

SINAMICS S120 – now integrated into the TIA Selection Tool

The initial phase involves integrating the SINAMICS S120 Booksize Active Line/Motor modules into the TIA Selection Tool, which makes dimensioning and configuration quick and easy. This makes it simple for you to use application-specific criteria to define your automation and drive design, including control, motor, gear unit, and converter. After that, the industry Mall gathers the relevant product listings and paperwork for your order.

Quick: Complete project configuration with just a few inputs

Easy: Technically always up-to-date about product portfolio and innovative approaches

Smart: Smart selection wizard for error-free configuration and ordering, pre-testing and simulating

“SINAMICS DriveSim Basic” simulation

With little parameterisation work and ease of use, the virtualisation program “DriveSim Designer” enables the accurate simulation of all SINAMICS S120 device types. The simulation tool imports a standardised “Functional Mock-up Unit” (FMU) straight into it. Even before the design stage, drive configurations in machines can be simulated, modified, and optimised using specific drive parameters and interfaces. Unlike the actual product, just the necessary portion of the drive can be configured in the simulation. This improves quality, speeds up the planning process overall, and saves time.

The control system and mechanical interface, including virtual commissioning of the PLC, can be automatically tested and validated through the use of “DriveSim Designer”.

Suitable applications for SINAMICS S120

- Moving: The drive for compressing, ventilating, and pumping is SINAMICS

- Processing: SINAMICS is the engine that powers continuous operations with precise torque and rapid speed.

- Positioning: The drive for placing one or more coordinated axes is know as SINAMICS

- Machinery: All material processing applications rely on SINAMICS

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.