Revolutionizing Modern Technology with Cutting-Edge Innovation

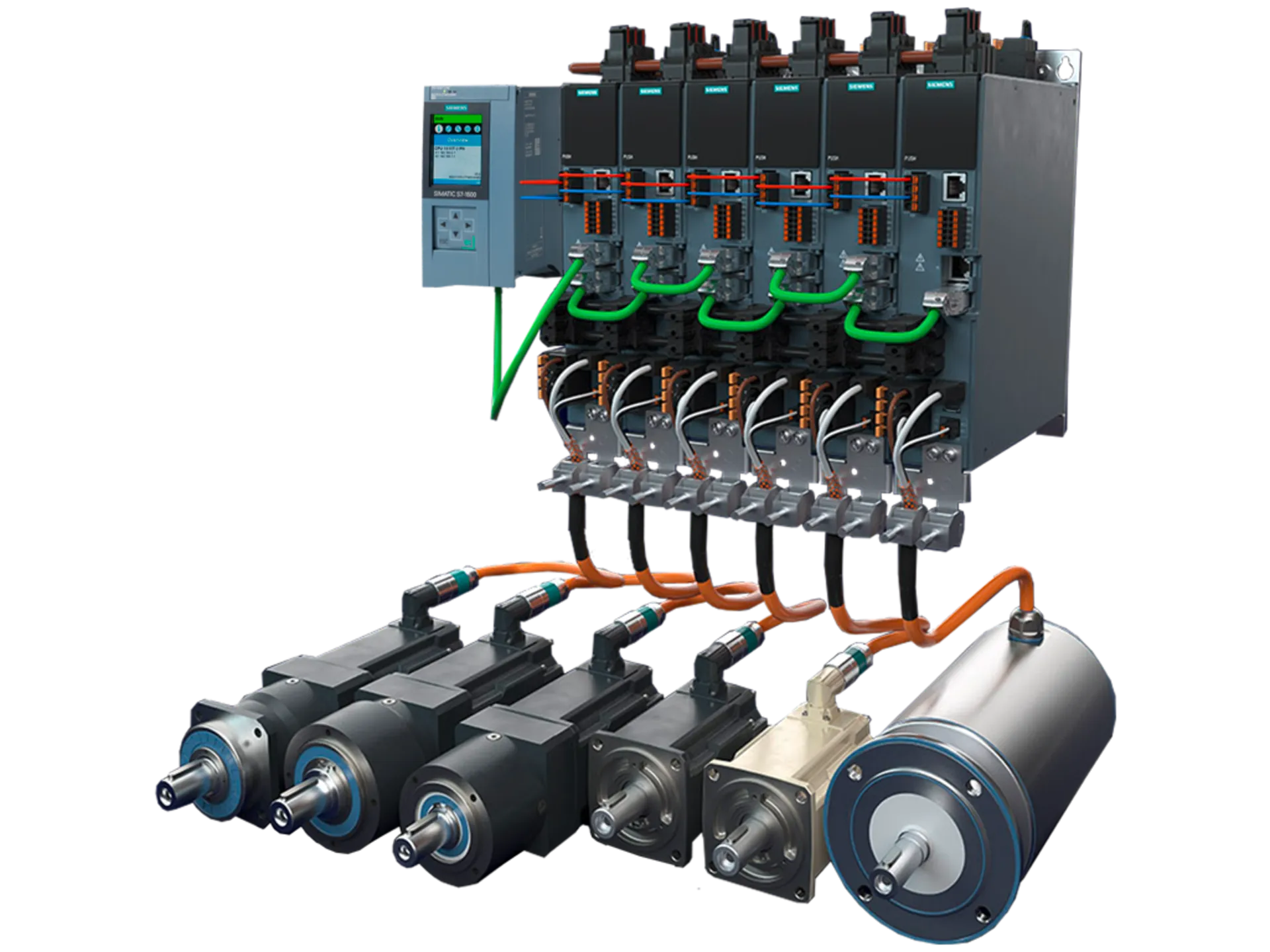

Thanks to enhanced hardware and software, as well as integrated safety and technological features, the SINMAICS S210 servo drive system is raising the bar for dynamic applications across numerous industries. A servo drive and servo motor make up the SINAMICS S210 system, which is intended for high dynamics solutions with power ranges of 50W to 7kW. Find out what you can do.

Your Servo system with strong advantages is the SINAMICS S210.

Versatile

- SINAMICS S210 is flexible and versatile. They move light loads with a high dynamic performance – and average and large loads very precisely

- In conjunction with the technological functions of the higher-level controller, there are many possibilities of motion. To reduce the load on the controller, positioning can also be carried out directly in the drive with the basic positioner (EPOS) (from V6.3).

- The SINAMICS S210 servo drive has an integrated PROFINET IRT (Isochronous Real Time) communications interface for connecting to a control system. Alternatively, from V6.3 onwards, the drive can also be connected to a third-party control system via EtherNet/IP.

Precise

- Low moment of inertia and high overload capability of the motor

- High-resolution encoders with fast sensing and an additional 2nd encoder interface for a direct measuring system

- Short cycle times on the machine are possible even with complex motion control

Safe

- Standard safety concept Safety Integrated. Machine safety for operating and maintenance personnel.

- Integrated safety functions: STO, SBC, SS1-t (time controlled), SS1*, SS2*, SOS*, SLS*, SSM*, SDI*, SLA*, SBT* (*can be optionally activated using a license)

- Seamless implementation of safety functions in accordance with SIL 2 (EN 61508) and PL d (EN ISO 13849-1), the new SINAMICS S210 in SIL3 (EN 61508) and PL e (EN ISO 13849-1)

Security Integrated – Innovation of the new SINAMICS S210

The new SINAMICS S210 provides safe factory default settings, individual user control, and secure communication between the servo drive and the TIA Portal engineering system, further strengthening our drives’ defences against cyberattacks. To stop altered firmware from being installed, access control, integrity checks, and authentication procedures are added.

A wizard walks you through the most crucial security-relevant settings when you use the integrated web server or the Startdrive engineering software for commissioning (TIA Portal).

Single-axis drive-based control: SINAMICS EPOS fundamental positioning feature

The integrated positioning function (EPOS) of the SINAMICS drive system allows for the absolute and relative positioning of individual linear and rotary axes using a motor or machine encoder. The TIA Portal/Startdrive will be used to engineer the drive’s EPOS function.

Selecting step by step

We will walk you through the entire process of getting your servo drive system, from the best servo motor for your application to the best servo converter, the appropriate cables and connectors, and the best controller.

Step:1 Run a motion control application simulation

Incorporate the drivetrain’s digital twin into your machine simulation to expedite the design and engineering stage while enhancing the robustness and quality of your machine! For designing, commissioning, and optimising your drive train system, DriveSim Designer and DriveSim Engineer are the best options available.

Step 2: The ideal servomotor

SIMOTICS S-1FK2 servomotors – the dynamic and compact solution

When combined with a SINAMICS S210 servo converter in a drive system, SIMOTICS S-1FK2 servomotors offer strong closed-control with excellent dynamic performance, quick control and positioning times, and a quick and accurate control response to disturbances.

There are two servomotor versions available, depending on the particular application:

- For Highley dynamic applications with low moving masses, the SIMOTICS S-1FK2 high dynamic offers the highest dynamic response thanks its low inertia

- Compact SIMOTICS S-1FK2: medium to high masses must be moved with a medium moment of inertia under precise, stable control.

Advantages

- Highest dynamic response as a result of the low rotor intrinsic inertia and the high overload capability

- Space-saving design as a result of the optimized frame size with a high power density

- High precision as a result of the high-resolution 22-bit single turn or multiturn absolute encoder

- High IP64 degree of protection of the motor – can be optionally increased to IP65

SIMOTICS S-1FT2 servomotors – the optimizable motor solution

To better address the various constraints of drive technology, the SIMOTICS S-1FT2 servo motor provides a range of extra possibilities. For instance, system precision is increased by encoders with a high resolution of up to 26 bits. A higher level of protection up to IP67 and several motor paint finishers are available in tough locations. There are also new machine possibilities with greater rated speeds. The motors can be more easily adjusted to specific operating circumstances since they have the option of self-cooling and, in the case of frame size 80, forced ventilation. Both the high Dynamic and Compact Moment of Inertia versions of the SIMOTICS S-1FT2 servo motor are available. For applications requiring a high dynamic performance with minimal masses to be moved, the High Dynamic versions provides the maximum dynamic responsiveness because of its low inherent inertia. With a medium intrinsic moment of inertia, the Compact versions offers remarkable, accurate, and steady closed-loop control of medium of high masses.

Advantages

- High dynamics due to low rotor inertia and high overload capacity

- High accuracy with up to 26-bit resolution single-turn or multi-turn absolute encoders

- Robust operation in harsh and humid environments with extendable protection up to IP67 and various coating options

- Greater variety of winding designs compared to SIMOTICS S-1FK2 for higher nominal and maximum speeds

- Increased cooling performance through forced ventilation, allowing for higher power density and more compact size

- Space-saving design with optimized size and high power density

SIMOTICS S-1FS2 Hygienic design servomotor – the solution for the food, beverage and pharmaceutical industries

For specific applications in the food, beverage, and pharmaceutical industries as well as plants and systems where regular SIMOTICS S-1FK2 and S-FT2 servomotors are insufficient, SIMOTICS S-1FT2 servomotors enhance the motor portfolio for the SINAMICS S210 servo drive system. The four sizes of this stainless steel motor series, which operates under extremely hygienic circumstances, range in power from 0.45 to 2 kW and torque from 3.1 Nm to 23.5 Nm.

Advantages

- High IP66 / IP67 degree of protection for the complete motor, IP69k (30 bar) motor housing

- Suitable for cleaning in place processes (CIP) using commercially available cleaning agents

- Meets the requirements of the pharmaceutical and food industry: 1.4404 stainless steel enclosure, EPDM seals, bearing grease with NSF H1 approval

- Design according to EHEDG guidelines

- High accuracy thanks to high-resolution 22-bit multiturn absolute encoder

- Shaft and flange compatible with SIMOTICS S-1FK2 and S-1FT2 servomotors

SIMOTICS S-1FK2 and S-1FT2 planetary servo gearmotors – the pre-assembled geared motor solution

With a lightweight and low-inertia gearbox design, or inertia adjustments for precise movement of heavy loads, SIMOTICS S-1FK2 and S1FT 2 servo planetary gearmotors allow for the highest cycle rates.

Due to the large variety of gearbox sizes and ratios, these geared motor drives can be precisely tailored to the application. Thermal dimensioning is as easy as for a servomotor using the digital twin of the geared motor that is included in the TIA Selection Tool.

Gearbox versions

- Gearbox NRB/NRBW: The NRB(W) is the lightest gearbox with the highest power density. As a result of its low-friction bearing design, it has a low intrinsic temperature rise and is suitable for high speeds.

- Gearbox NRK/NRKW: As a result of their large output bearings, NRK(W) gearboxes are suitable for higher radial and axial forces. Thanks to their low inner friction, these gearboxes are also suitable for higher speeds.

- Gearbox NLC/NLCW: As a result of their pretensioned tarped rolling bearings, the NLC(W) gearbox has a high degree of stiffness, and is the perfect choice for high radial and axial load levels. These gearboxes are protected against dust and water thanks to their IP65 sealing system.

Advantages

- Optimum adaptation of the torque-speed or the mass moment of inertia relationship between the motor and load

- Pre-assembled, tested and ready-to-run servo geared motor solutions

Step 3: The optimum servo drive

SINAMICS S210 servo converter

The power range of the SINAMICS S210 servo drive is 0.1 to 7kW. Utilising a SIMOTICS servomotor from the S-1FK2 or S-1FT2 product line, the system is primarily intended for sporadic equipment construction applications that demand a high level of dynamic performance. When the application calls for accurate positioning and motion control, SINAMICS S210 makes the most of its advantages. Every motion sequence is executed with the maximum level of accuracy, even with the most dynamic performance. SINMAICS S210’s exceptional performance make it compelling choice for digital printing, woodworking, plastics processing, handling systems, and packaging equipment.

Step 4: The matching cables

Motor connecting cables – OCC (One cable connection)

The SINAMICS S210 servo system’s motor and frequency converter are all connected by a single cable, which also serves as an encoder and brake controller. Easy connection that doesn’t require any extra equipment.

Available cables:

- MOTION-CONNECT 400 for fixed routing (only for SIMOTICS S-1FS2)

- MOTION-CONNECT 500 cables are used for predominantly fixed routing

- MOTION-CONNECT 800PLUS cables when routing cables in moving cable carriers (drag chains).

The cables can be ordered prefabricated with the required length.

Extension cables and motor connection cables

- SPEED-CONNECT plug connector on the motor side of a prefabricated OCC motor connecting cable (shield terminal provided in the scope of delivery)

- Siemens IX signal connector on the converter side and SPEED-CONNECT plug connector on the motor side of a prefabricated OCC motor connecting cable (shield terminal included in the scope of delivery)

- Extension cable that is prefabricated

Step 5: The matching controller

SIMATIC S7-1200 G2 for basic motion control applications

Completely integrated into TIA Portal, a comprehensive approach using the SIMATIC S7-1200 G2 controller and the SINAMICS 210 servo drive system allows operation in the basic automation sector. Positioning, synchronous operation, cams, and others motion control applications are developed using SIMATIC technology objects and run safety and deterministically at predetermined internals using PROFINET IRT and PROFIsafe via PROFINET.

For a strong safety concept, suitable fail-safe SIMATIC variations are available.

SIMATIC S7-1500 for advanced motion control applications

For complex motion control applications programmed in TIA Portal, the SINAMICS S210 servo drive with PROFINET is an ideal coordinated and harmonised solution when used in conjunction with the SIMATIC S7-1500 and SIMATIC S7-1500 T-CPU. The SIMATIC technology objects found in the SIMATIC S7-1500 control are used to implement motion control functions, including positioning, synchronous operation, cams, etc. For safety applications, the suitable fail-safe SIMATIC variations are available. Clock-synchronous PROFINET IRT is used to link to the SINAMICS S210 servo drive system

Step 6: The user-friendly accessory for your operation

SINAMICS Smart Adapter

The Smart Adapter is a useful plug-and-play accessory that enhances the system. It allows a wireless connection (via WiFi) between a laptop or mobile device and the SINAMICS S210 servo drive system during commissioning, operation, or diagnostics. Its compact design makes it perfect for carry-on luggage and eliminates the need for extra charging or batteries.

Planning, Configuring, engineering and commissioning

Selection tools

- You can easily locate the appropriate drive on your smartphone with the SINAMICS Selector App.

- You can configure your drive with the help of the Siemens Product Configurator (SPC)

- You can define the mechanics and choose and design drives and motors with the help of the TIA selection Tool (TST). Project outcomes and energy and performance estimations are provided by SIZER for Siemens Drives.

- The Digital Twin is used for virtualisation and simulation.

Commissioning tools

- Together with features like the SINAMOICS Smart Adapter for Wi-Fi connectivity and more, the integrated web server guarantees effective setup, diagnostics, and maintenance.

- Through the TIA Portal, SINAMICS Startdrive facilities the methodical commissioning and integration of the system into the automation environment.

SINAMICS S210: Sustainable and energy-efficient

Siemens EcoTech

The goal of Siemens EcoTech, an environmental product performance mark, is to promote the long-term, sustainable transformation of infrastructure and industry. The mark enables you to make well-informed decisions that support your sustainability goals by making the performance of our certified items transparent across environmentally relevant criteria. This environmental label includes the SIMOTICS S-1FT2 servo motor and the SINMAICS S210 servo drive system.

Analyze the lifecycle of your drive system

At Alpha Drives & Switchgear, we are committed to supplying equipment that is both environmentally responsible and sustainably produced. We work with manufactures who avoid the use of hazardous substances in their products while maintaining the highest performance standards for our customers. Through the Environmental Product Declaration (EPD), we provide the ability to assess the full lifecycle of your drive system.

Service Protect offers extended warranty coverage

The warranty coverage for your SINAMICS S210 servo drives or SIMOTICS motors can be extended up to 7 years with various options.

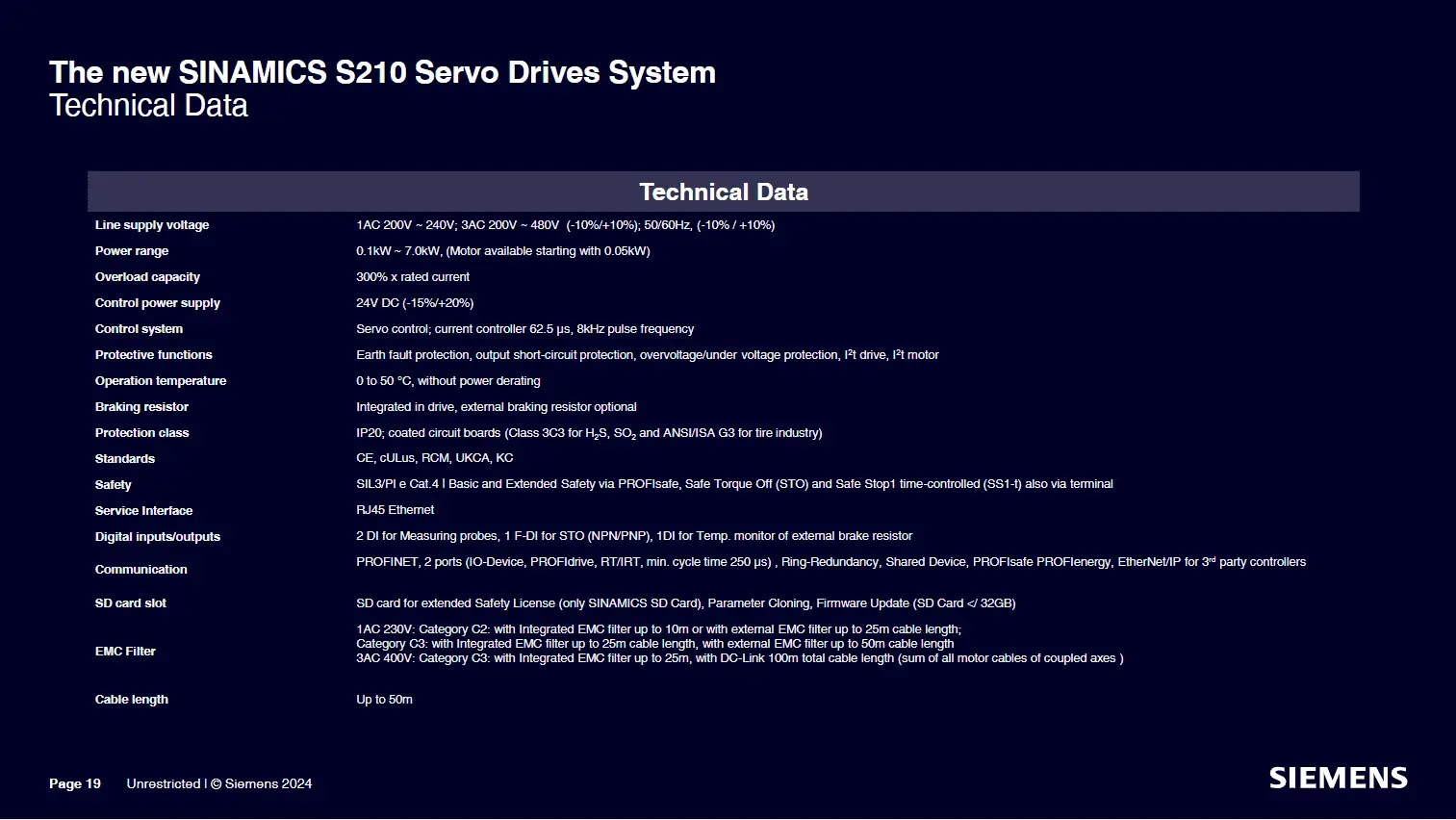

S210 Technical Data

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.