Innomotics SD Severe duty motors

Motors for Challenging Conditions

In both harsh and typical industrial settings, the heavy-duty motors with their sturdy cast iron casing are the preferred option for all significant applications. They are incredibly dependable, especially in harsh environments, adaptable, incredibly small, and manageable. Extremely high efficiency guarantee sustainable and cost-effective operation.

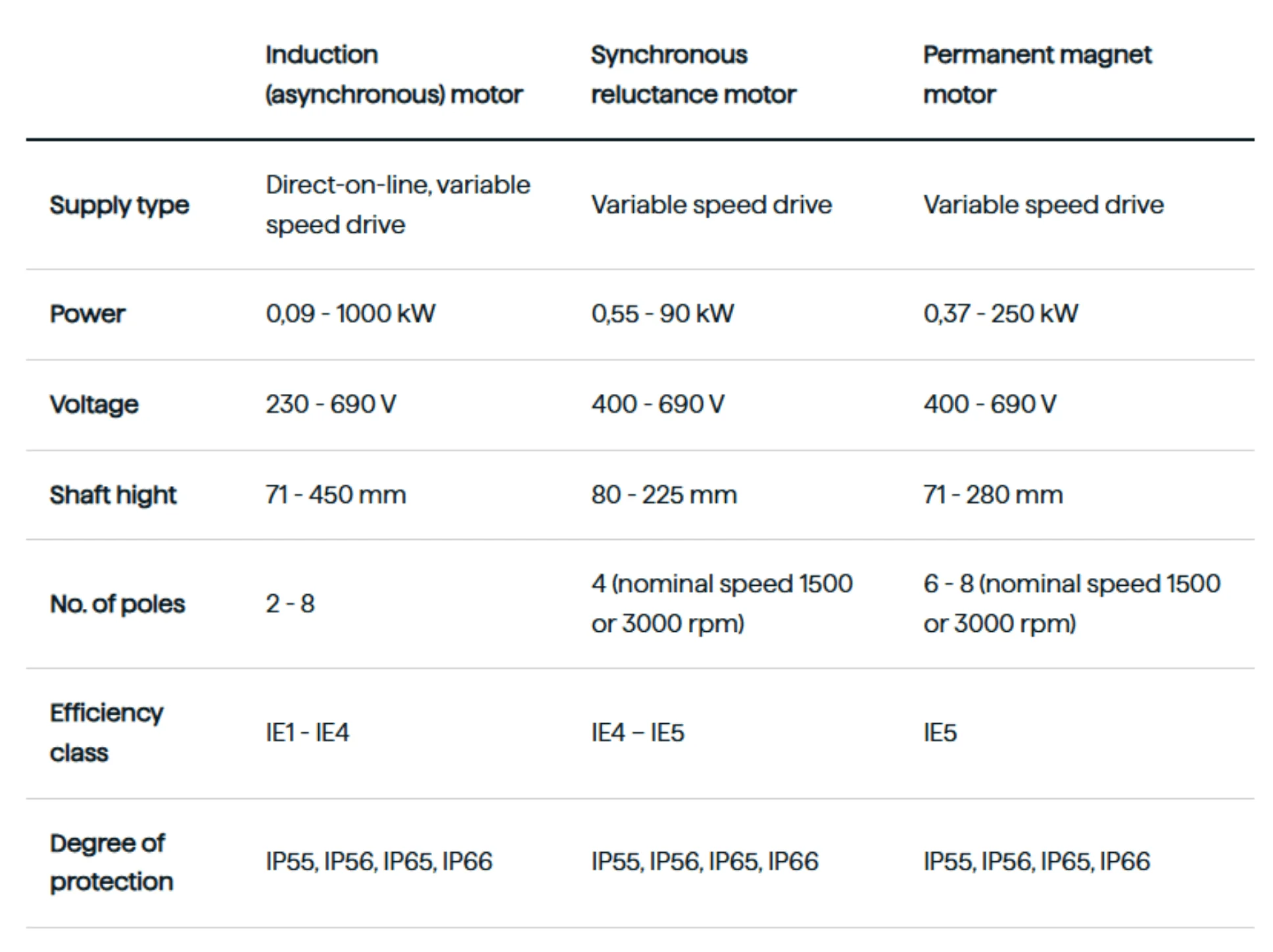

Two distinct synchronous motor technologies are provided in addition to induction (asynchronous) Motors for direct-on-line and convertor operation. These must always be utilised in conjunction with frequency converters (VSD).

Direct on line, converter capable motors

The well-proven Innomotics SD Severe duty motors induction motors come in efficiency classes up to IE4 and are designed for line operation. Since July 2023, safe area motors with nominal power between 75 and 200 kW and two to six poles that are sold in the European economic area have been required to be of IE4 class.

However, by providing IE4 designs ranging from 2.2 to 1000kW, up to 8 poles, the Innomotics SD portfolio significantly exceeds these limitations. There are also other catalogue variations, such the incredibly small increased power line motors, which have a shaft height that is one step lower.

Converter-optimized motors

On the Innomotics SD Severe duty motors platform, the variable-speed drive motors are built. The mechanical components are the same, and the design matches that of the line motors. But instead of using the squirrel cage induction rotor, they use one of the two synchronous technologies that are available. Additionally, a lot of the options, terminal box location, motor protection, and construction kinds that are available for line motors are also accessible for VSD motors.

- Motor for synchronous reluctance

The greatest option for extremely for extremely energy-efficient operation while maintaining the usual power-shaft height assignment is a VSD system with an Innomotics reluctance motor. Without a rotor winding, the reluctance techniques guarantees exceptionally high dynamic performance, high efficiencies, and good process quality, especially in the partial load range.

- Motors with permanent magnets

This cutting-edge technology, which uses permanent magnets in the rotor, allows for a high power density in addition to exceptional IE5 energy efficiency. Compared to an induction motor with the same power rating, a permanent magnet motor may even be three frames sizes smaller. These motors also cover extreme overloads and overspeed’s and offer a steady torque from the lowest speed.

Your benefits at a glance

Future-oriented energy efficiency concepts

Environmental friendliness due to lower carbon emissions and increased competitiveness due to energy savings.

- Large selection of IE4 class motors: Super premium efficient motors in a range of design variations, with capacities ranging from 2.2 to 1000kW, are available, significantly surpassing the required standards.

- IES2 compliance for drive systems in accordance with IEC 61800-9-2: Determine the precise system losses of SIEMENS SINAMICS convertors in conjunction with Innomotics SD Motors

Best-in-class-design

Improved flexibility and efficiency throughout the installation process.

- Future-proof and compact design: For increased power line types and larger power densities at similar performance levels.

- Smaller overall measurements: to save space and facilitate replacement.

- The new idea for a terminal box is to provide more flexibility when integrating systems.

- Better operational quality: For low starting currents (IS/IN) or high starting or break loose torques (TS/TN).

- Applications that are flexible include mains and convertors with a voltage of up to 690 V.

Reliability in harsh environments

Strong and durable cast iron housing with modifications available.

- Painting system up to CX offshore: Extremely resilient in harsh environments.

- IP66 protection class:Suitable for extremely humid or dusty conditions.

- -50 to +60°C ambient temperature range: dependable performance under harsh weather conditions

Simple and fast processes

Achieve your next level of performance along the value-added chain.

- Extremely quick delivery timeframes with choices: Increase your planning time and flexibility.

- Additional setup choices: For quicker quotations and quicker response times, employ a larger variety of standardised alternatives. All backed by strong web resources.

- Global reach: adherence to regional regulations and important international certifications.

Technology overview

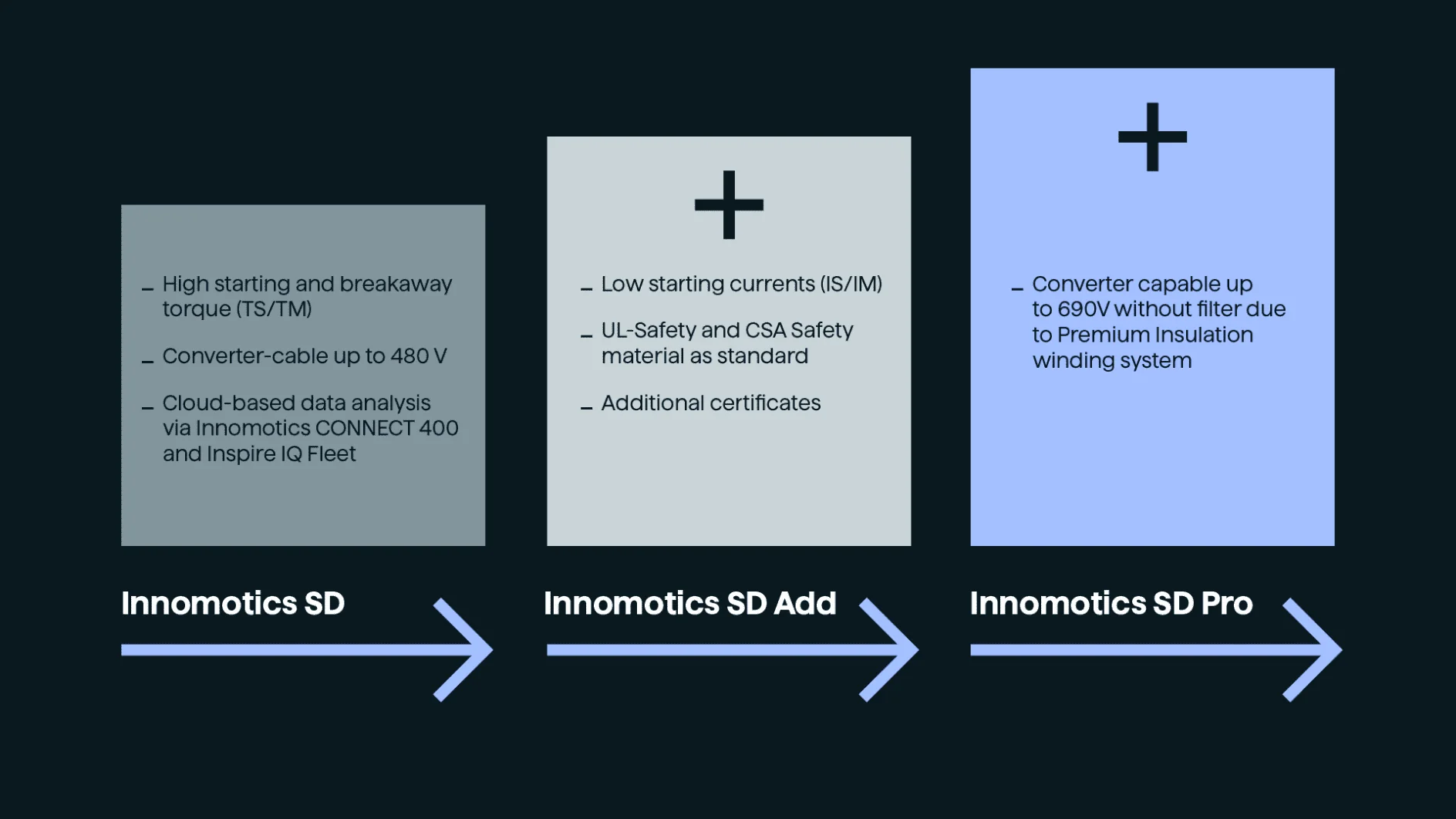

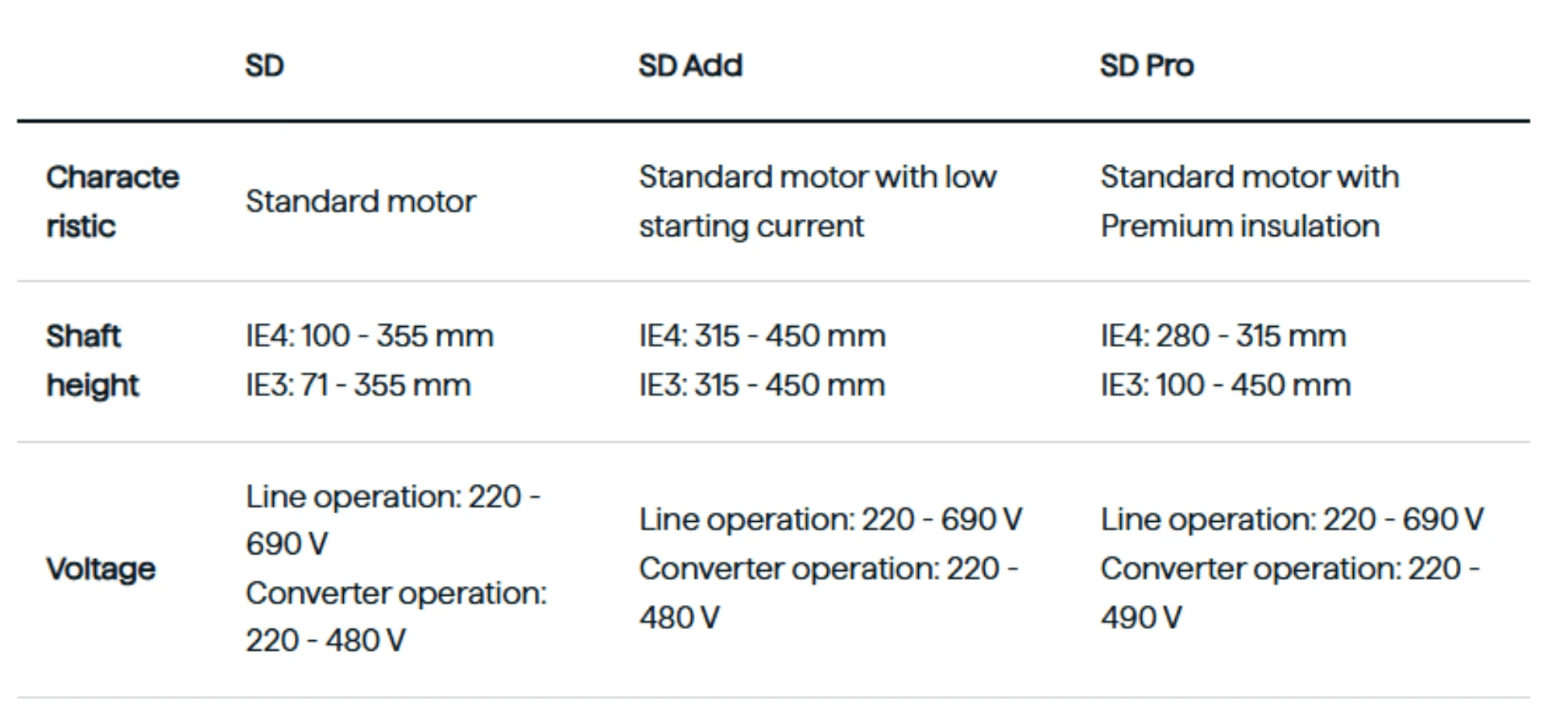

Induction motors-design variants

By default, global certificates are provided by Innomotics SD Add and Innomotics SD Pro. As a result, they are ready for usage by default in all major global markets and regions. Both North america and the European Union can utilise them as standards. Additionally, in compliance with IEC and EISA regulations, they are provided with the electrical values stamped on the rating plate. The motors are electrically equivalent to a NEMA version (Mechanically according to IEC), just like the eagle-line for the smaller shaft heights. There are also numerous additional country-specific certifications available.

Technology overview

Providing compelling answers for your sector

The following industries’ standard applications, including pumps, fans, compressors, conveyors, winders, mixers, extruders, and cranes, are ideal for Innomotics SD Severe Duty Motors.

- Cement Industry: Use Innomotics products to boost the effectiveness of every procedure in your cement manufacturing plant.

- Chemical Industry: Your plant will succeed throughout its whole life cycle if you have an integrated portfolio

- Oil and Gas Industry: Numerous obstacles must be overcome by the oil and gas sector in order to explore, produce, transport, store, refine, and distribute. Having a very dependable and secure framework for automation, digitisation, and electrification is one of the difficulties.

- Pulp and Paper: Your solid technological partner offers pulp and paper, tissue plant, and innovative, dependable, and Highley efficient products and systems

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.