Solutions For Plastics Machines

Rubber/tires, extrusion, blow moulding, thermoforming, injection moulding, and handling With our portfolio of Digital Enterprise solutions, you can achieve the best possible product quality, maximum availability, and flexibility. With our standards for software, automation, and driving technology, you can get quicker development times and a quicker time-to-market.

Multiple Applications In One Library.

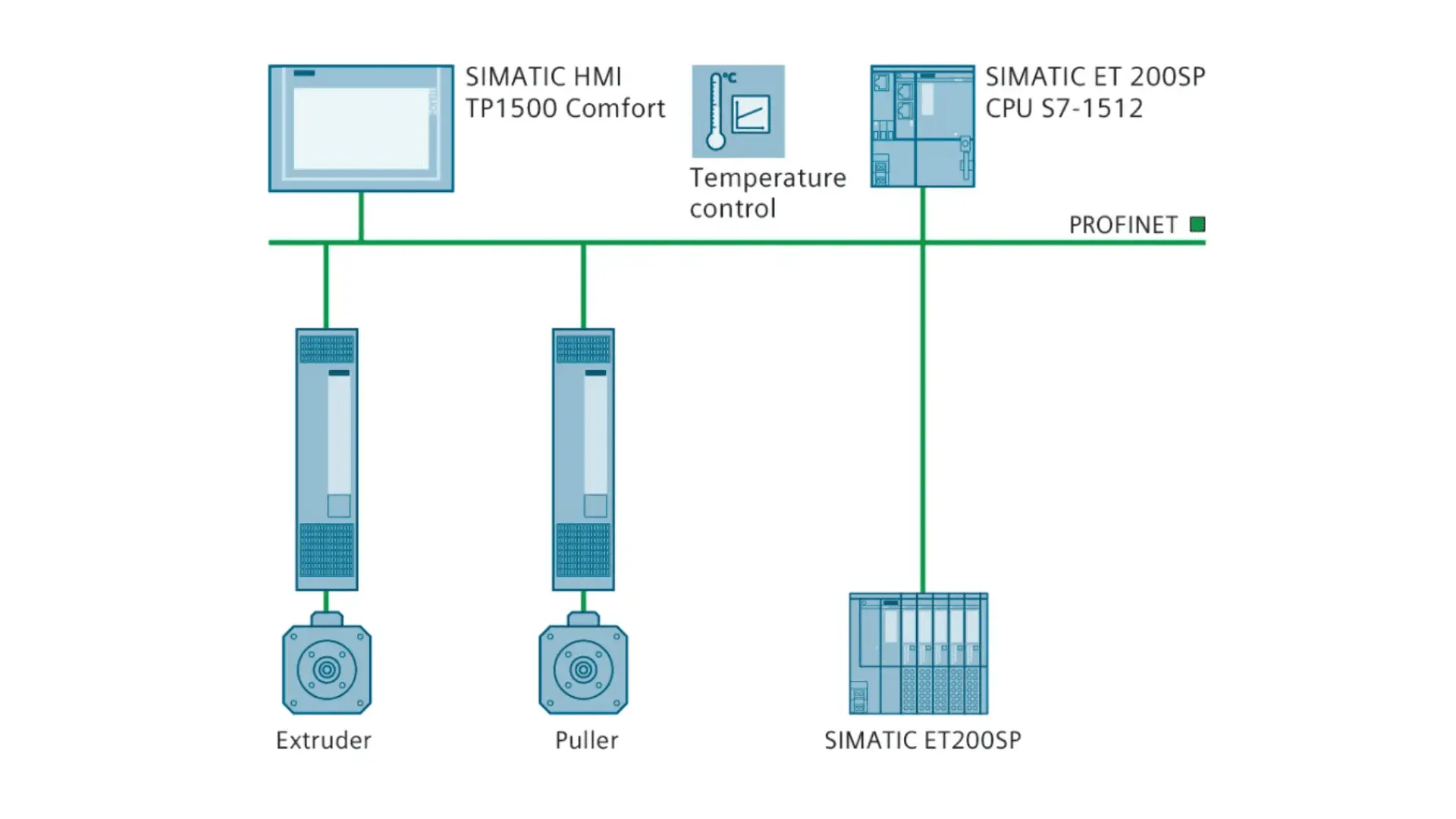

The foundation of the most recent generation of machines is the SIEMENS modular software library. Whether it’s motion control, wall thickness control, drive packages, temperature control, or parameterizable sequence control, this standardised software blocks have the ideal answer for each need. The SIMATIC S7-1500 hardware serves as the standard foundation for the software library, and each module comes with an operational HMI.

Standard Applications: A Quick And Affordable Way To Build Completed Machinery

Any plastics machine solution starts with freely combinable, pre-tested blocks from the plastics library and a consistent hardware basis with SIMATIC ET 200SP Open Controller, SIMATIC S7-1500, SINAMICS drives, and SIMOTICS motors.

Customised Fixes For Injection Moulding Equipment

We offer the appropriate automation technology for your needs, regardless of the kind of injection moulding machine you use—hydraulic, hybrid, or entirely electric. All of the main functions of your electric injection moulding machine are covered by our SIMATIC-based application solution.

Benefits at a glance

- High degree of flexibility thanks to scalable products and systems based on standard components

- Straightforward and convenient operation of the complete machine

- Scaled performance of operating components optimized to suit requirements

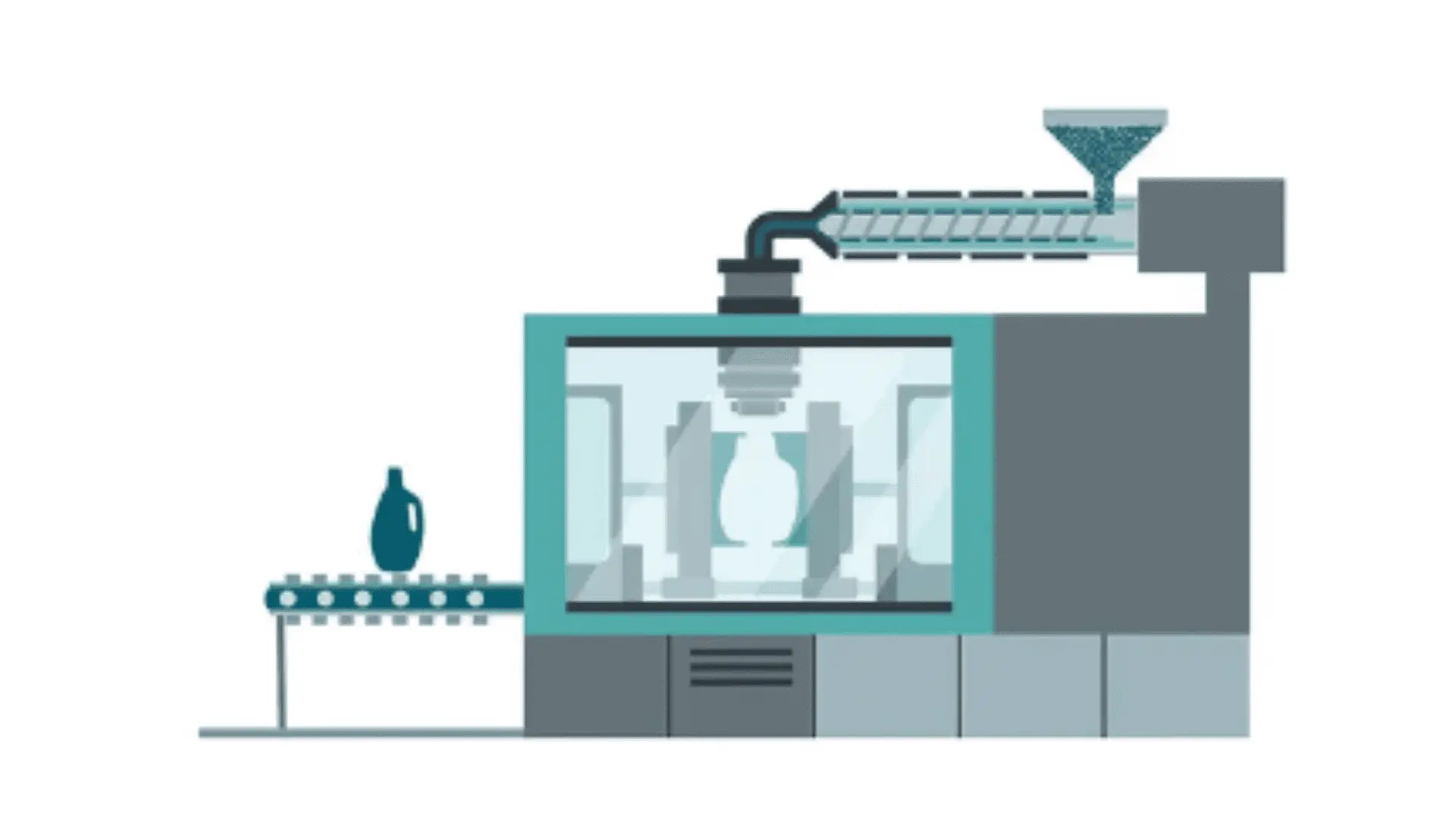

Increased Blow Moulding Machine Efficiency

Whether your blow moulding machine needs to be powered by electricity or hydraulics, we offer the ideal automation solution for PET processing in one or more stages. Are you trying to find a way to swiftly and economically put blow moulding concepts into practice? The ideal foundation is provided by our SIMATIC S7-based BMM 1500 blow moulding kit, which uses tested hardware, preconfigured software, and an adaptable visualisation approach with ready-made graphics.

Benefits at a glance

- Modular, integrated technology modules enable easy scalability and adaptability

- Proven, open solutions are provided using the standard range of SIMATIC S7 modules and the open STEP 7 system

- A large TFT touch panel with a clear intuitive user interface

- Simple recipes storage on a USB flash drive

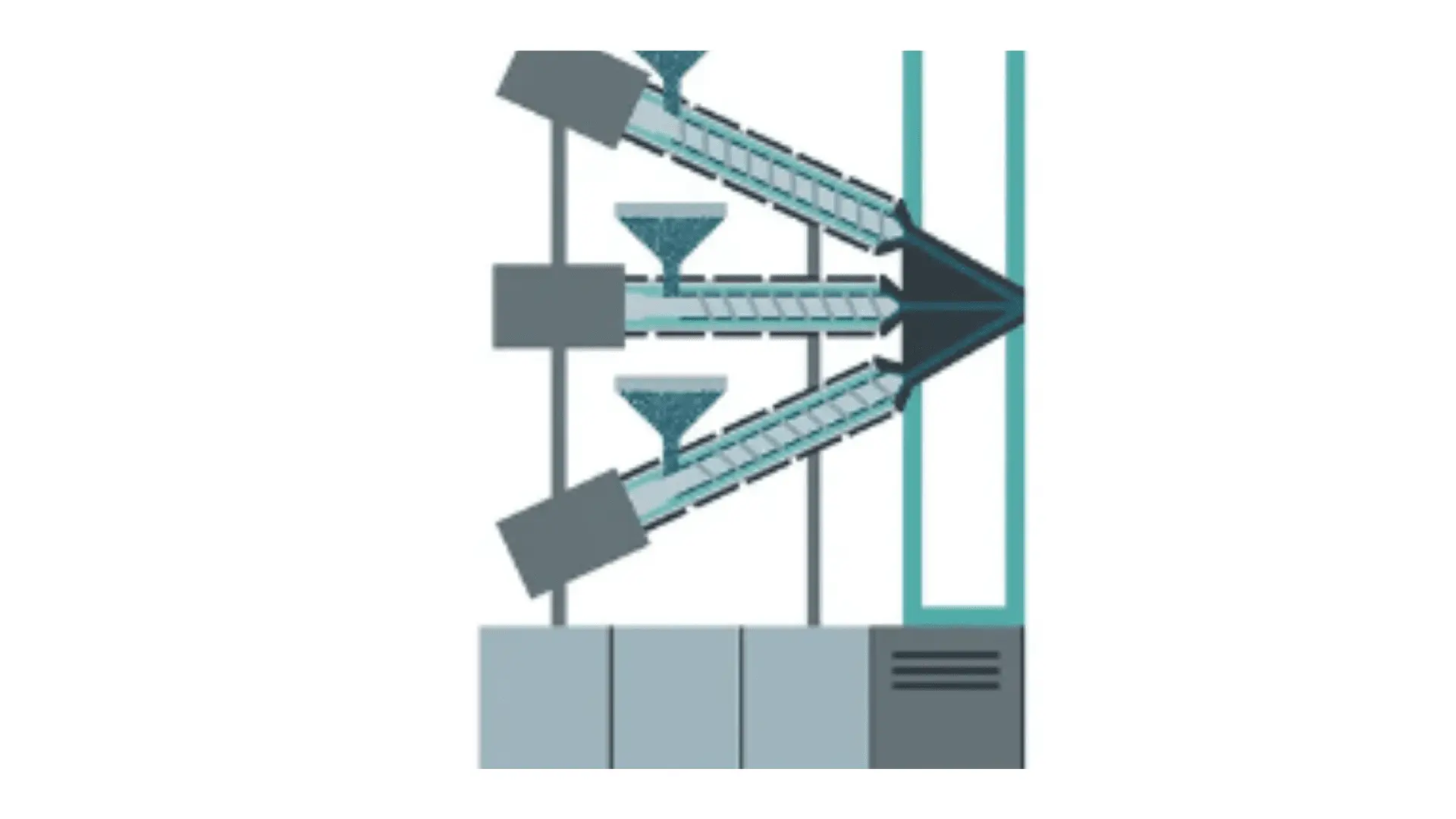

Integrated Automation Of Extrusion Machines

Our high-performance visualization and control systems provide extrusion solutions that are easy to adapt to specific production requirements. With integrated software for controlling and operating all the different parts of the plant around the extruder, you can operate downstream equipment, sensors for product testing, melt pumps and dosing devices using just one controller.

Benefits at a glance

- Easy operation through clear user interfaces and large TFT touch panel using modern WinCC Comfort visualization software

- Cost savings thanks to a complete solution for extrusion machines comprising a factory-fitted software package and modular hardware

- Flexibility and expandability based on the global industrial standards SIMATIC S7 and Totally Integrated Automation

- Increased cost-efficiency thanks to integrated economy functions in the temperature control system

Accuracy In Thermoforming Apparatuses

Hundreds of separate radiant heaters are frequently needed for thermoforming, and each one needs to be carefully adjusted or reset for a different mould. In terms of product quality, even a few degrees of variance can have a significant impact. Accurate mate- ing between the table and top dies is necessary for a flawless moulding process. The TMF 1500 is our solution for accurate thermoforming; its clear heat imaging allows for extremely quick temperature setting. Because their axis motion is jerk-free and exact to the next millimetre, high-precision motors and drives also contribute to maintaining consistent quality.

Benefits at a glance

- Individual thermoforming solution thanks to scalable products and systems based on standard components

- Precise and fast temperature control

- Performance gradation of the heating process optimized to suit requirements

- Large TFT touch panel with temperature graphics

Topology Extrusion Machine

Siemens Solutions For The Plastic Industry

In the plastic industry, precision, efficiency, and reliability are paramount. At Alpha Drives Ltd., we understand the unique challenges faced by plastic manufacturers, which is why we partner with Siemens, a world leader in industrial automation and control technology, to provide comprehensive solutions tailored to the needs of the plastic industry. Let’s explore some key Siemens components that Alpha Drives Ltd. integrates into plastic manufacturing processes:

1. Siemens Drives and Motors

Siemens offers a wide range of drives and motors specifically designed for the plastic industry. These components provide precise control over speed, torque, and positioning, ensuring optimal performance and energy efficiency in plastic processing equipment such as extruders, injection molding machines, and blow molding machines.

Siemens SINAMICS Drives

SINAMICS drives offer seamless integration with various control systems and communication protocols, allowing for flexible and efficient operation of plastic manufacturing equipment.

Siemens SIMOTICS Motors

SIMOTICS motors are renowned for their reliability and performance, delivering high torque density and low vibration for smooth and consistent operation in demanding plastic processing applications.

2. Siemens PLCs (Programmable Logic Controllers)

Siemens PLCs serve as the brain of automation systems in plastic manufacturing plants, controlling and coordinating the operation of machinery and processes. These powerful controllers offer advanced functionality, real-time monitoring, and seamless integration with other Siemens components.

Siemens SIMATIC S7 PLCs

SIMATIC S7 PLCs provide scalable solutions for small to large-scale plastic manufacturing operations. With features such as high-speed processing, modular expansion, and built-in diagnostics, SIMATIC S7 PLCs ensure efficient and reliable control of production processes.

3. Siemens HMI (Human Machine Interface)

Siemens HMI solutions offer intuitive and user-friendly interfaces for operators to monitor and control plastic manufacturing equipment in real time. With high-resolution touchscreens, customizable layouts, and remote access capabilities, Siemens HMI panels enhance productivity and ease of operation on the factory floor.

SIMATIC HMI panels provide seamless integration with Siemens PLCs and other automation components, enabling operators to visualize process data, set parameters, and diagnose issues with ease.

4. Siemens Industrial Networking Solutions

Siemens offers a comprehensive portfolio of industrial networking solutions to ensure seamless communication and connectivity between various components in the plastic manufacturing environment. From Ethernet switches and routers to wireless access points and industrial communication protocols, Siemens networking products facilitate reliable data exchange and control.

Siemens SCALANCE Networking Devices

SCALANCE networking devices enable secure and efficient communication between PLCs, HMIs, drives, and other devices in the plastic manufacturing plant, ensuring smooth operation and optimal performance. At Alpha Drives Ltd., we leverage the expertise and innovation of Siemens to deliver tailored solutions that address the unique needs of the plastic industry. By integrating Siemens drives, motors, PLCs, HMIs, and networking solutions into plastic manufacturing processes, we help our customers achieve greater efficiency, productivity, and competitiveness in a rapidly evolving market.

Partner with Alpha Drives Ltd. for Siemens Solutions That Drive Success in the Plastic Industry.