Upgrade for uptime

Invest in Flender AIQ detect for your flexible coupling to increase operational dependability and reduce unscheduled downtime.

FLENDER AIQ detect will save you time, money and resource’s

Your flexible N-EUPEX and RUPEX coupling becomes a smart component with Flender AIQ detect. In addition to measuring rotational direction and speed, the digital coupling sensor tracks the elastomers’ state of wear. This enables you to continuously check the state of your coupling.

Reduce the amount of downtime

By using AIQ Detect to continuously and permanently monitor the clutch, unanticipated failures can be avoided and operational reliability is increased. But more importantly, it serves as the foundation for condition-based maintenance. Flender AIQ detect has made it possible to replace the elastomers only when required and in a targeted manner rather than at regular intervals. this is sustainable in addition to being cost-effective.

Save effort

Using legitimate measured values, Flender AIQ Detect consistently evaluates the state of your flexible coupling. As a result, staff members do not need to be trained or instructed in monitoring. The sensor signals a change in condition as soon as the elastomers’ wear limit is surpassed. There is still time to schedule upkeep. The system may be unavailable for several hours during yearly routine maintenance. Long-term, Flender AIQ detect can spare you this work.

Check the function

In addition to monitoring the elastomers’ wear, the sensors logs each coupling revolution. Flender AIQ Detect can calculate and report the rotational speed and direction based on this data. This enables you to guarantee that the driveline is always moving correctly.

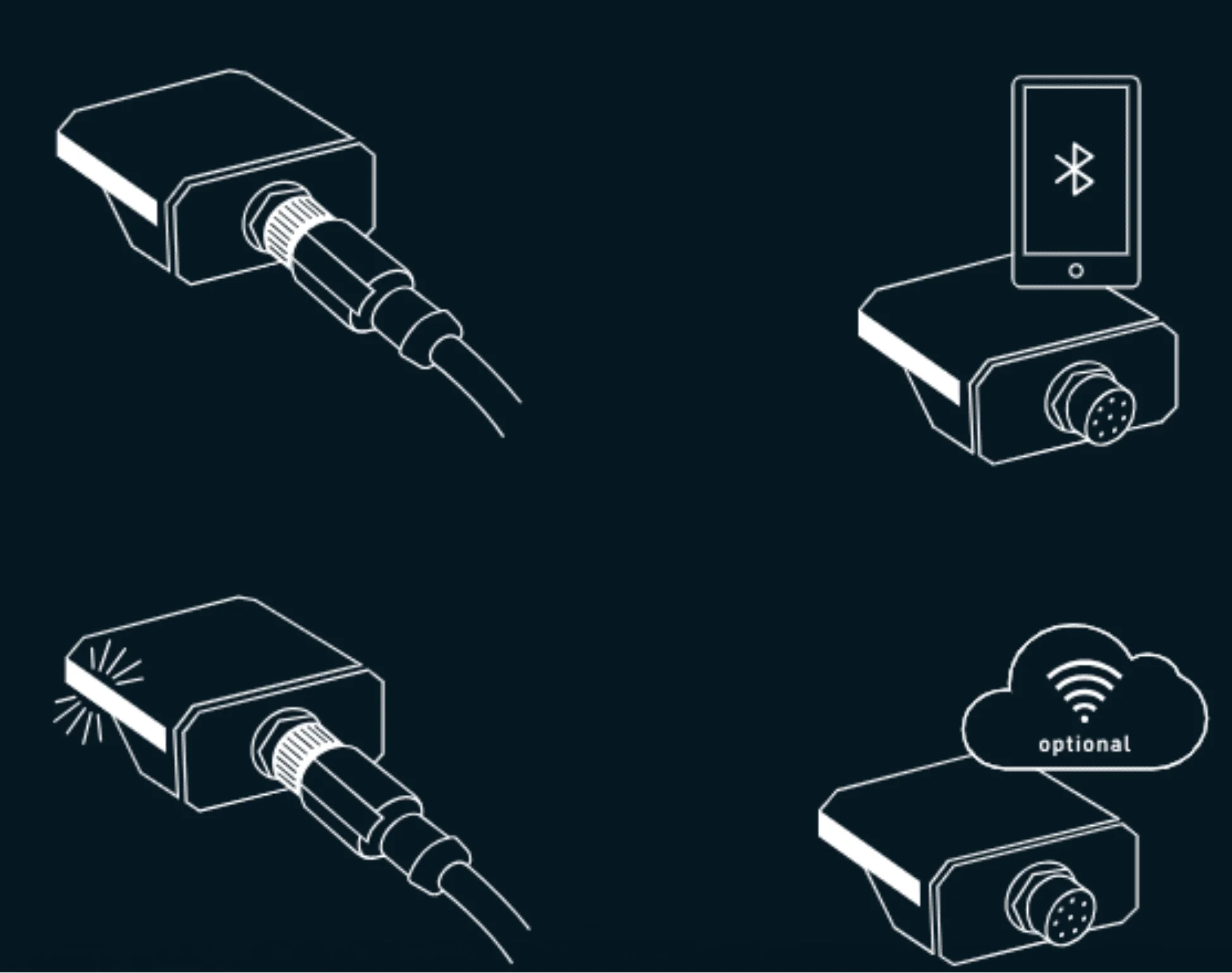

Extensive connection options for convenient status monitoring

You can always monitor your coupling with Flender AIQ Detect. A coloured LED light strip is used directly display the elastomers’ wear state on the sensor. Additionally, you can use a Bluetooth connection to access the status via the Flender AIQ app. You can connect to your system controller via a wired PLC interface. The connection assignment and warnings can be changed. The Flender AIQ Portal also allows you to keep an eye on the coupling status online. This is accomplished by connecting the Flender AIQ detect to an already existing Flender AIQ Core, which transmits data via its WiFi connection. The data sheet, which you may download straight as a PDF file, and the box on the right include an overview of all technical facts.

Easy retrofit or direct ordering

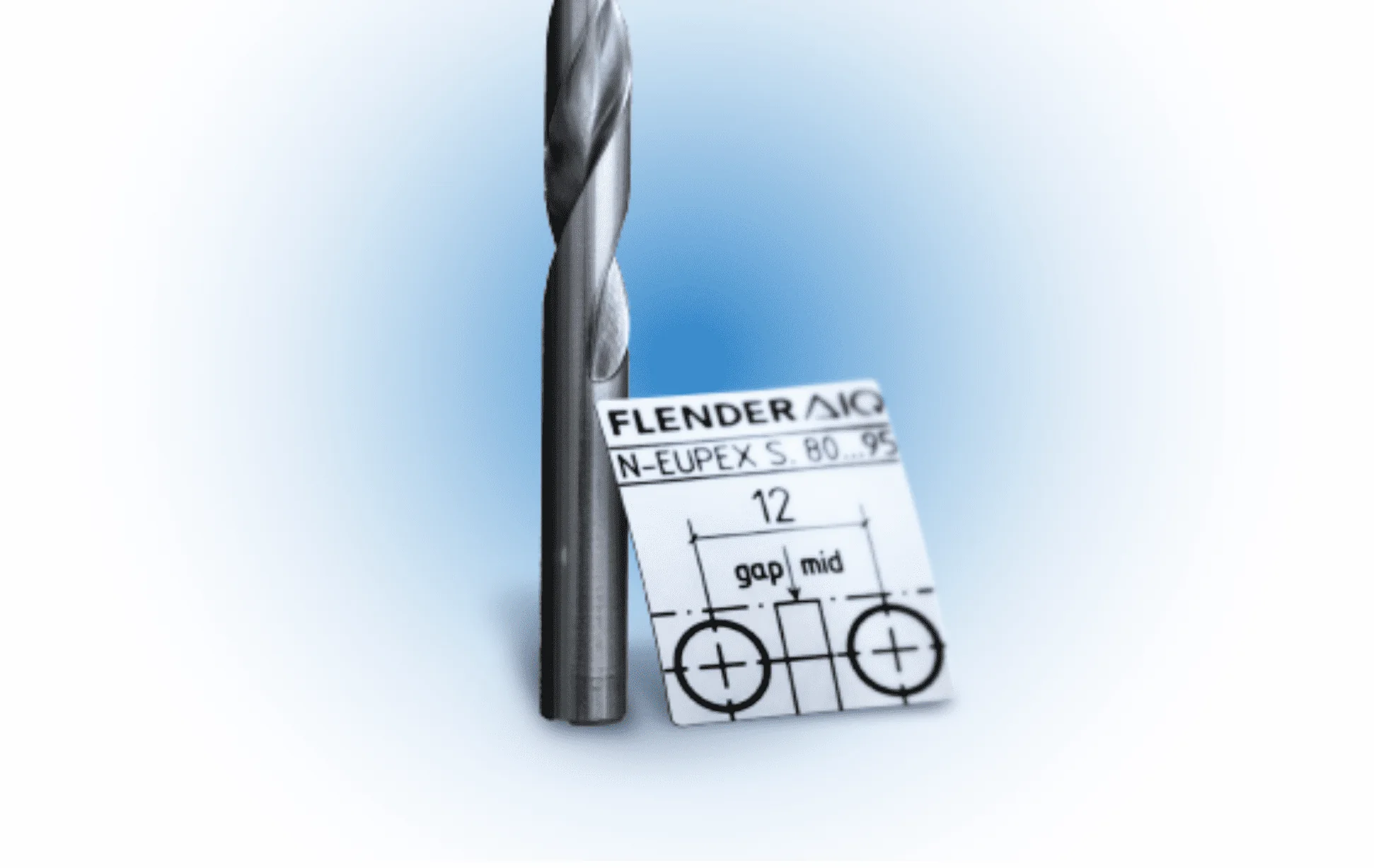

You can choose to configure a new N-EUPEX or RUPEX with the Flender AIQ detect ready option when you place your order. The Magnets required for the sensor measurements will subsequently be installed in your coupling. After that, the Flender AIQ detect is prepared for usage. Naturally, you may order the Flender AIQ Detect is prepared for usage. Naturally, you may order the Flender AIQ Detect sensor at the same time. After installation, you can start monitoring the clutch’s condition right away. Additionally, Flender AIQ detect may be retrofitted to any N-EUPEX or RUPEX, making it simple to add intelligence to your current couplings. The next step is to refit the magnets needed for the measurement.

UPGRADE PACKAGE

- Flender AIQ Detect Sensor

- Extra Strong Magnets

- Quick Guide

INSTALLATION KIT

- Special drill with 6 mm diameter and depth of cut, specially adapted to the magnets to be installed

- Self-adhesive template for easy and optimal positioning of the drill holes

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.