Innomotics GP general purpose motors

General-purpose motors with aluminium housing, IP66 protection, and C4 painting systems are appropriate for a variety of common drive duties in humid and industrial settings. The motors’ architecture and design guarantee optimal flexibility and little installation work. Their exceptionally low weight makes them ideal for use in compressors, fans, and pumps.

Product Overview

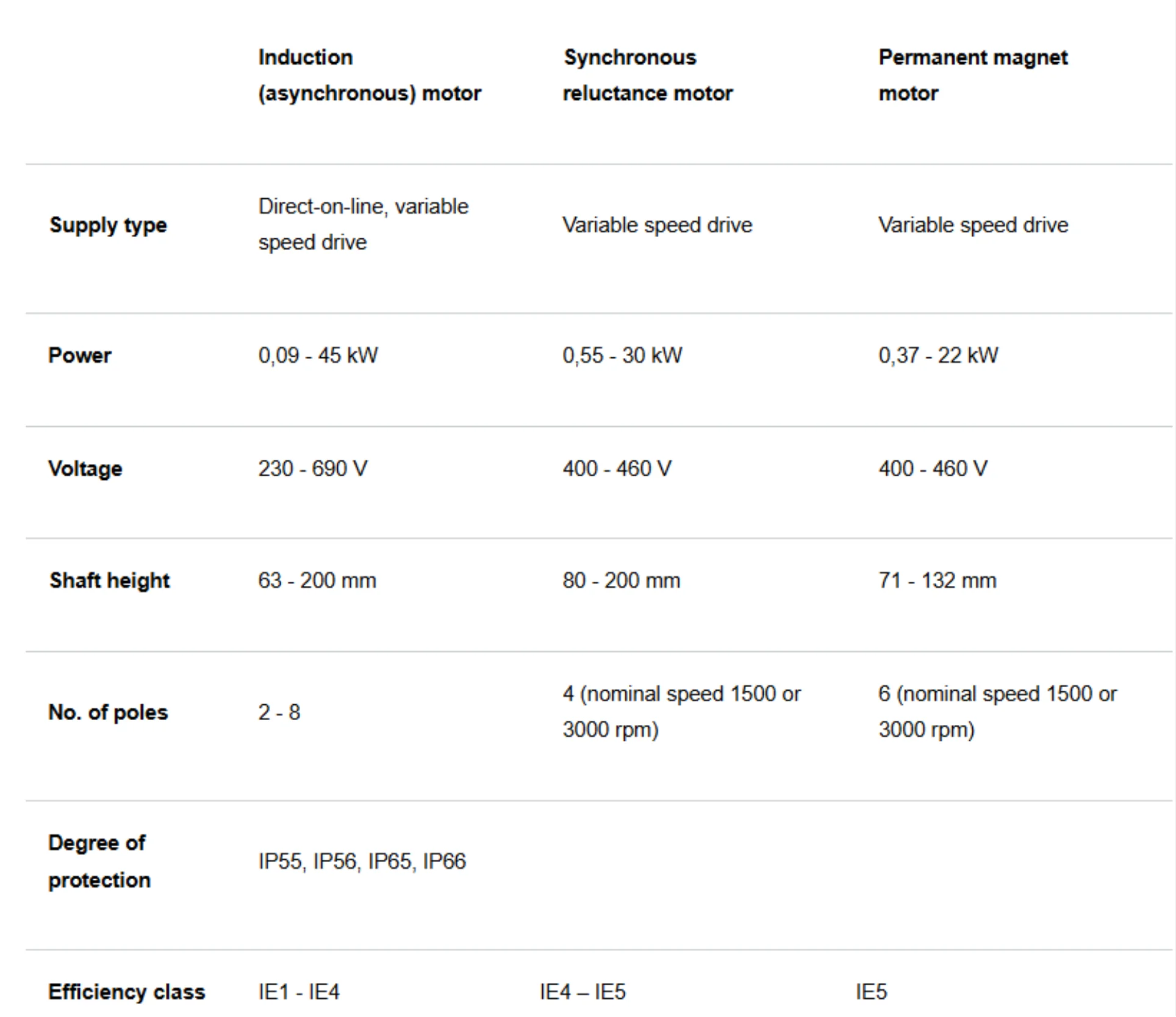

Two distinct synchronous motor technologies are provided in addition to induction (synchronous) motors for direct-on-line and converter operation. These must always be utilised in conjunction with frequency converters (VSD).

Direct on line, converter capable motors

Available in efficiency classes up to IE4, well-proven induction motors from Innomotics GP general purpose motors are tuned for line operation. The Power-shaft height assignment is the same for all motors. Because there are no variations in shaft height, servicing or replacing motors in all efficiency classes is simple. Convertors can also be used to run these grid-optimized motors.

Convertor-optimized motors

The Innomotics GP General Purpose Motors platform serves as the foundation for the variable-speed drive motors.The mechanical components of the design are the same as those of the line motors. However, they use one of the two synchronous technologies that are available in place of the squirrel cage induction rotor. They work exceptionally well and achieve very high energy efficiency (IE4 or IE5), even at partial loads, when combined with the right frequency convertor. Furthermore, the VSD motors have many of the same options as the line motors, including construction kinds, motor protection terminal box location, and other variants.

- Motor for synchronous reluctance

The greatest option for extremely energy-efficient operation while maintaining the usual power-shaft height assignment is a VSD system with an Innomotics reluctance motor. Without a rotor winding, the reluctance technique guarantees exceptionally high dynamic performance, high efficiencies, and good process quality, especially in the partial load range.

- Motor with permanent magnets

This cutting-edge technology, which uses permanent magnets in the rotor, allows for a high power density in addition to exceptional IE5 energy efficiency.Compared to an induction motor with the same power rating, a permanent magnet motor may even be three frame sizes smaller. These motors also cover extreme overloads and overspeed’s and offer a steady torque from the lowest speed.

Your benefits at a glance

- Aluminium structure that is lightweight and affordable

- Simple to use and really little

- Different types of motors for specific uses

- Easy, adaptable installation because of thoughtful design

Technical data overview

more similar articles

Our team are happy to help you with any questions or enquiry you have.

Send Us An Email

Our team are happy to help you with any questions or enquiry you have.